Large-cross-section box column and processing technology thereof

A box-shaped column, large-section technology, applied in the direction of columns, piers, pillars, etc., to achieve the effects of high bearing capacity, efficient and fast production, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described further below with embodiment, is not to limit the scope of implementation of the present invention hereto.

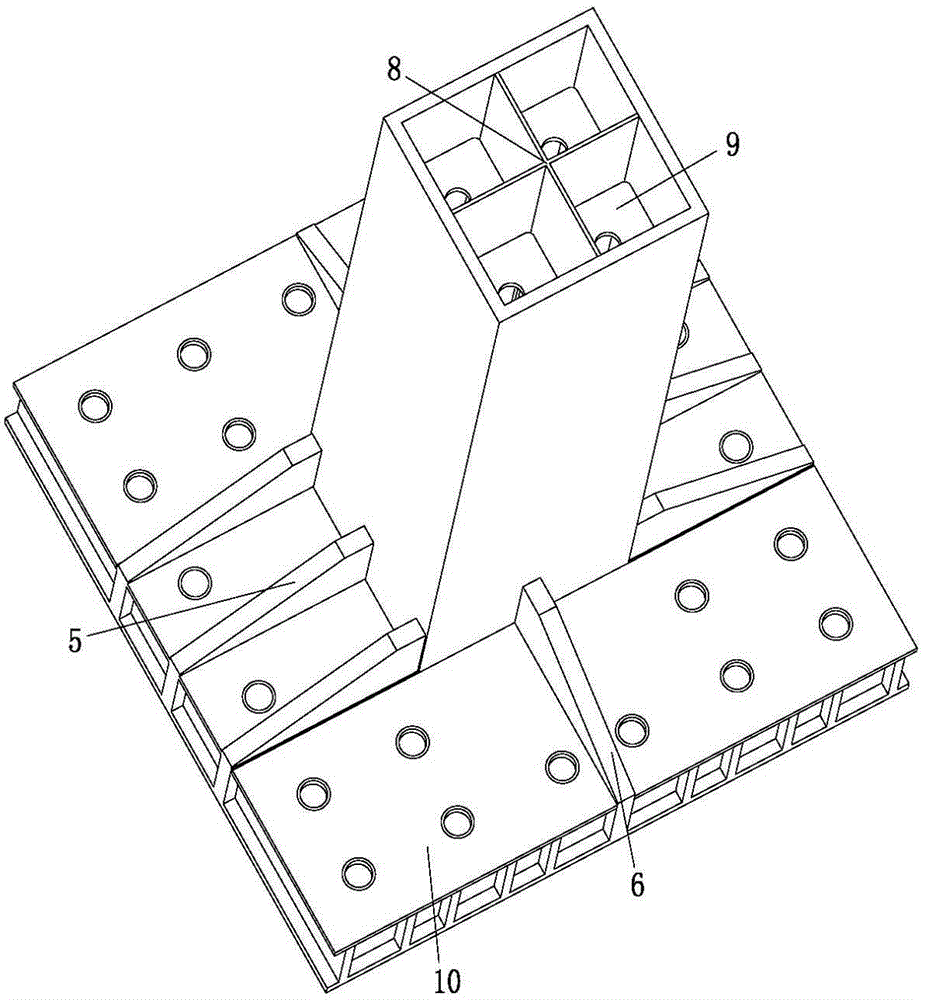

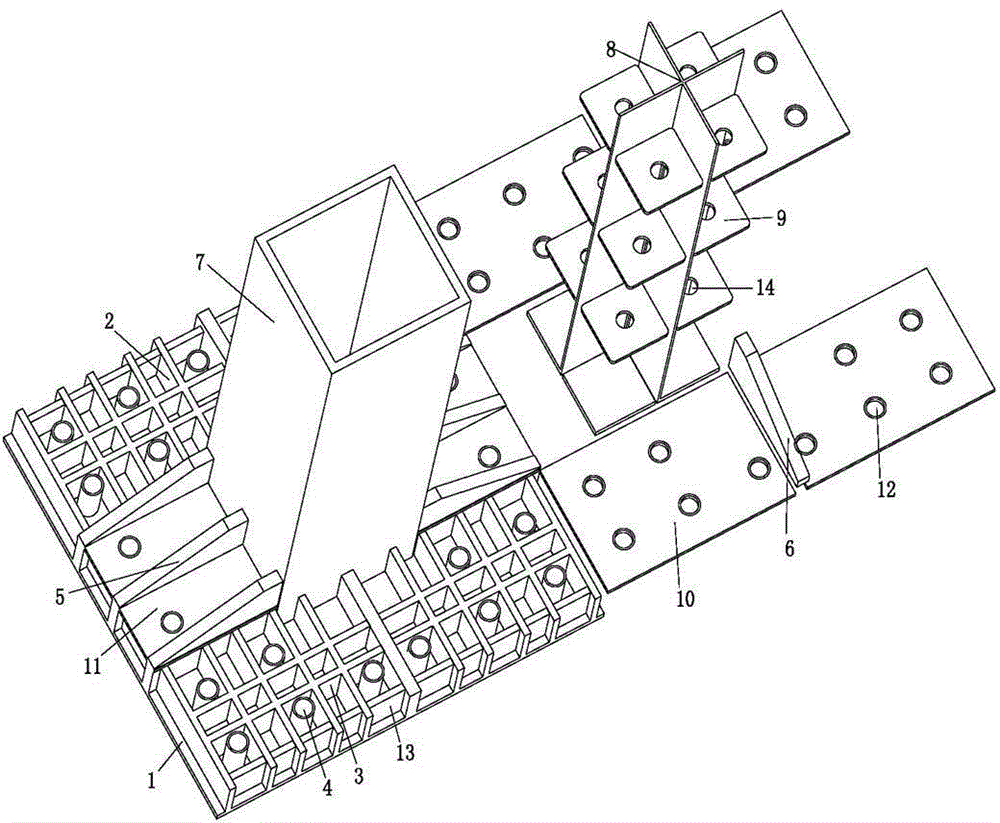

[0022] Such as figure 1 and figure 2 As shown, a large-section box-shaped column includes a bottom plate 1, and the bottom plate 1 is drawn with auxiliary stiffeners 2, small stiffeners 3, and positioning lines connected by positioning pins 4 before connecting other structures. There are box-shaped columns, and the outer edge of the box-shaped column is provided with a cover plate. There are several auxiliary stiffeners 2 and small stiffeners 3 connected vertically and horizontally between the cover plate and the bottom plate 1. The auxiliary stiffeners 2 and small stiffeners 3 are interlaced. Positioning pins 4 are arranged in the connected holes, main stiffeners 5 are connected to one of the symmetrical sides of the box-shaped column, and upper cover stiffeners 6 are connected to the other symmetrical two sides of the box-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com