Collagen membrane with highly oriented and crystalline collagen fiber structure and preparation method thereof

A technology of collagen fibers and collagen membranes, applied in medical science, prostheses, tissue regeneration, etc., can solve the problems of inconvenient material collection, limited orientation, mechanical inability to approach natural tendon, etc., and achieve fast and effective preparation and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

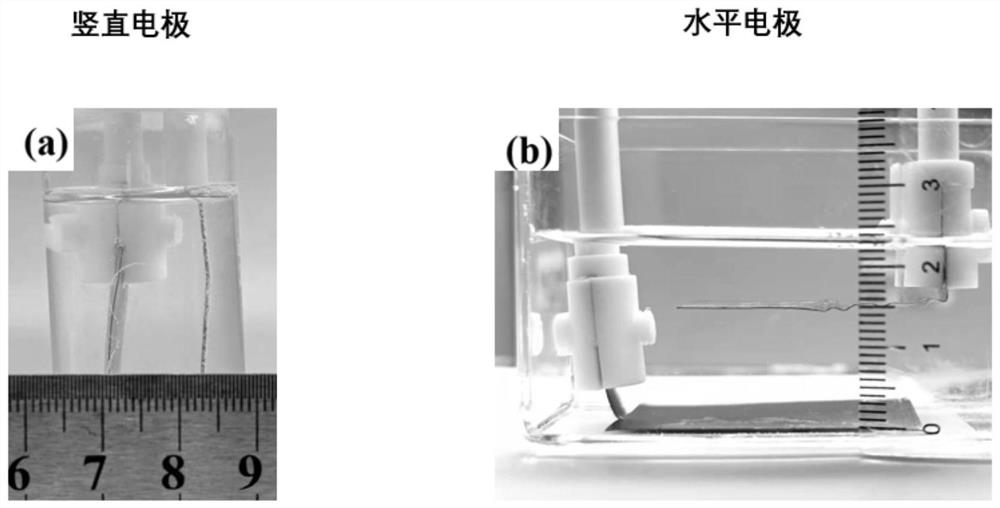

[0051] Example 1: Assembly of short-range oriented amorphous collagen materials by EDP technology

[0052] (1) Collagen solution configuration: Accurately weigh 400 mg of type I collagen into 40 mL of ultrapure water, dropwise add glacial acetic acid and stir well to promote complete dissolution of the collagen, and adjust the pH of the final solution to 3.5. Put it in a dialysis bag (M Wcut off =7.0kDa) and put it into a beaker containing 1000ml of water and 15ml of glacial acetic acid, and dialyzed at 4°C for 72h to remove small molecular impurities. A collagen viscous fluid of 10 mg / ml was obtained after dialysis. By changing the quality of the collagen raw material added, the final concentration of collagen solution can be adjusted in the range of 1-20 mg / ml. When the concentration exceeds 20 mg / ml, the solution loses fluidity.

[0053] (2) Add 100 μl / ml of hydrogen peroxide to the collagen solution described in step (1), stir evenly, centrifuge at 8000 rpm / min at 4°C to...

Embodiment 2: and preparation example I

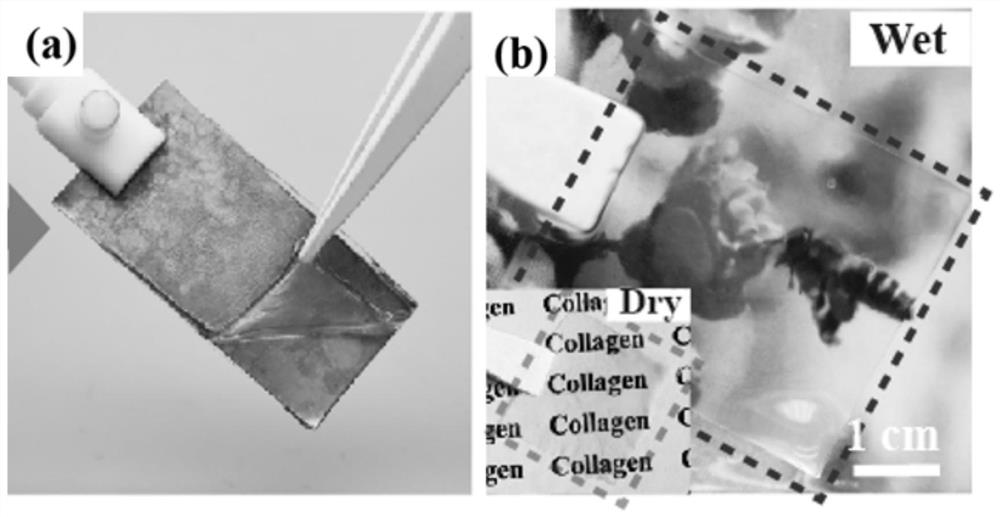

[0060] (1) Mechanical stretching

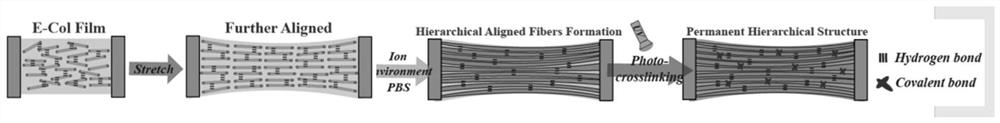

[0061] The collagen membrane E-Col was prepared according to the method of Example 1, and it was cut into a rectangular spline with a length of 30 mm and a width of 10 mm. Immerse several rectangular splines of E-Col in ultrapure water for 5 minutes, and then use Electro-Force 3200 biodynamic tester to stretch the length of the collagen membrane to a strain of 200%, so that the internal The microfibrils are further oriented along the force direction, forming a long-range oriented collagen material. Finally, the stretched E-Col was soaked in ethanol to temporarily fix the orientation structure.

[0062] (2) Ion incubation

[0063] Carry out ion incubation of the long-range oriented collagen material in step (1): fix both ends of the strip-shaped collagen membrane material in a petri dish with tape to keep the collagen membrane subject to continuous external force without shrinking, and then place the strip on the petri dish. 0.1M PBS buffer...

Embodiment 3

[0067] Example 3: Preparation Example II of Collagen Film with Highly Oriented and Crystalline Collagen Fiber Structure

[0068] (1) Mechanical stretching

[0069] The collagen membrane E-Col was prepared according to the method of Example 1, and it was cut into a rectangular spline with a length of 20 mm and a width of 20 mm. Immerse several rectangular splines of E-Col in ultrapure water for 10 minutes, and then use Electro-Force 3200 biodynamic tester to stretch the length of the collagen membrane to a strain of 50%, so that the internal collagen membrane is stretched to 50% strain. The microfibrils are further oriented along the force direction, forming a long-range oriented collagen material. Then, the stretched E-Col was soaked in ethanol to temporarily fix the orientation structure.

[0070] (2) Ion incubation

[0071] Incubate the highly oriented collagen material in step (1): fix both ends of the strip-shaped collagen membrane material in the petri dish with tape, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com