Systems and Methods for Stripping and/or Finishing Wood Surfaces

a wood surface and system technology, applied in the direction of gear teeth, manufacturing tools, manufacturing apparatus, etc., can solve the problems of time-consuming and laborious fixing process, many different materials, and uneven wood surface, etc., to achieve the effect of quick and efficient preparation of wood surface and quick and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention relates to systems and methods for stripping and / or finishing wood surfaces. Specifically, the present invention relates to using systems and methods utilizing rotary apparatuses having metal embedded industrial diamonds to cut, grind, and polish wood surfaces.

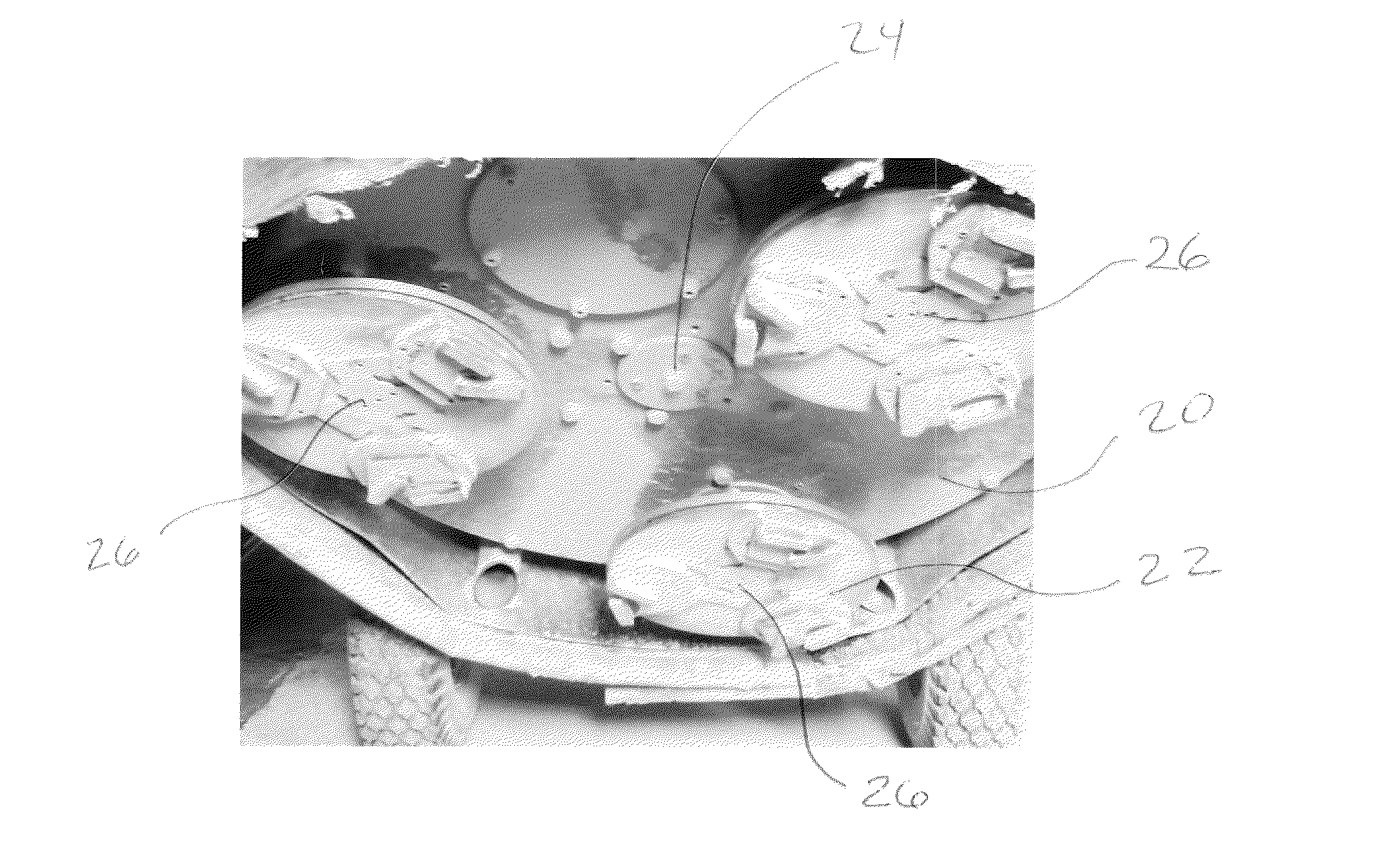

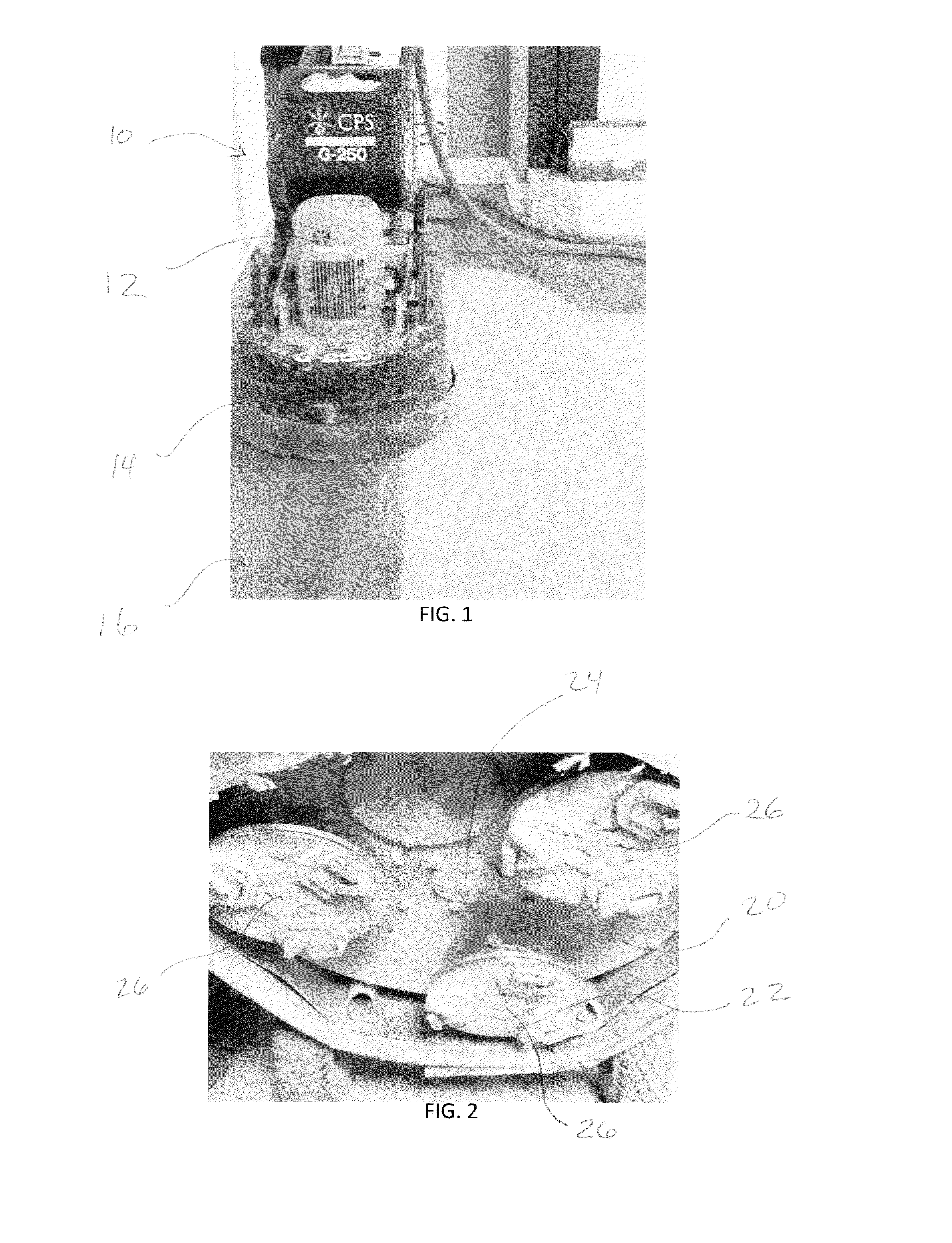

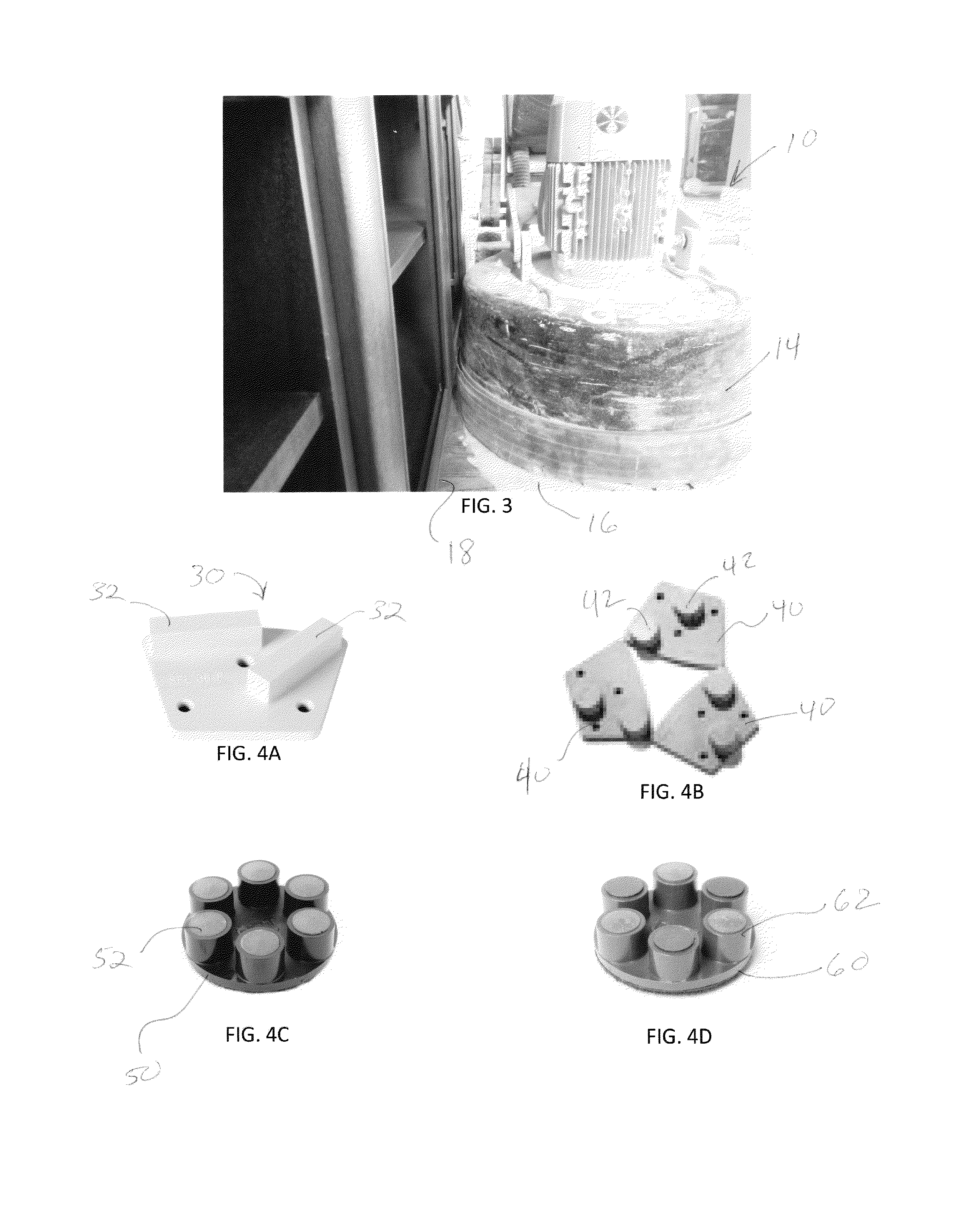

[0031]Now referring to the figures, wherein like numerals refer to like parts, FIG. 1 illustrates an apparatus 10 typically utilized for grinding concrete surfaces, known as a CPS G-250 rotary concrete grinder. It should be noted, however, that any rotary concrete grinder apparatus may be utilized in the present invention, and the present invention should not be limited as described herein. The rotary grinder apparatus 10 may have a motor 12 for imparting high speed rotation to a disc 20 having concrete grinding heads 22 thereon, as illustrated in FIG. 2. The disc 20 may be contained within a drum 14 utilized for housing the disc 20 and the grinding heads 22 therein.

[0032]The apparatus 10 is known f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| abrasive | aaaaa | aaaaa |

| grit sizes | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com