Preparation method of elastic conductive paste

An elastic conductive, paste technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve problems such as poor tensile electrical stability, changes in resistance characteristics, and low initial conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

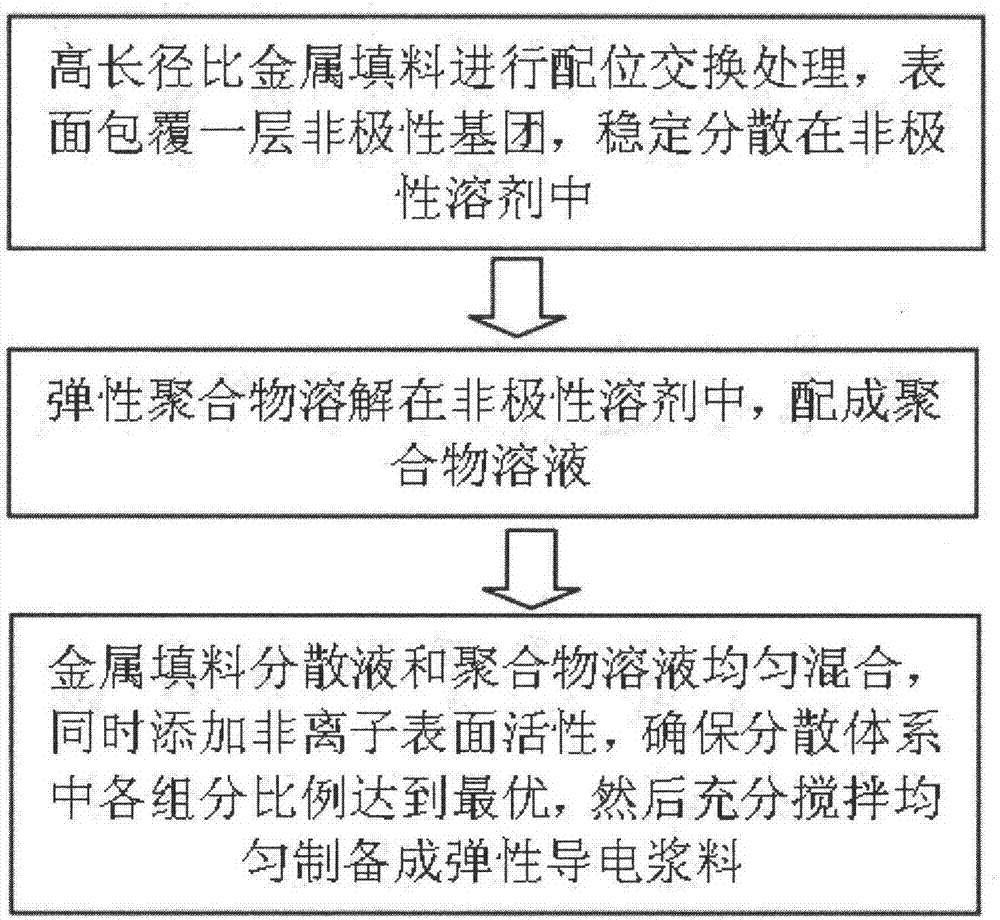

[0019] Specific embodiment one, please refer to figure 1 , a preparation method of elastic conductive paste, the steps are:

[0020] (1) First, carry out ligand exchange treatment on the surface of silver nanowires with an aspect ratio of 100-5000: 1, so that the surface is covered with a layer of non-polar groups, and then the silver nanowires are coated with 20-60wt% by weight Disperse in a non-polar solvent and make a stable dispersion for use;

[0021] (2) dissolving the elastic polymer in a non-polar solvent, according to the polymer solution of 10-50wt% by weight;

[0022] (3) The dispersion liquid prepared in step (1) and the polymer solution prepared in step (2) are mechanically mixed according to the mass ratio of the silver nanowires in the dispersion liquid to the elastic polymer in the polymer solution being 1.5-3.5:1 , and then add water-soluble nonionic surfactant whose mass is 10-30% of the mass of silver nanowires to the mixed system, and finally prepare the ...

specific Embodiment 2

[0024] Specific embodiment two, please refer to figure 1 , a preparation method of elastic conductive paste, the steps are:

[0025] (1) Firstly, ligand exchange treatment is performed on the surface of copper nanowires with an aspect ratio of 100-5000:1, so that the surface is covered with a layer of non-polar groups, and then the copper nanowires are coated with 20-60wt% by weight Disperse in a non-polar solvent and make a stable dispersion for use;

[0026] (2) dissolving the elastic polymer in a non-polar solvent, according to the polymer solution of 10-50wt% by weight;

[0027] (3) The dispersion liquid prepared in step (1) and the polymer solution prepared in step (2) are mechanically prepared according to the mass ratio of the copper nanowire in the dispersion liquid to the elastic polymer in the polymer solution being 1.5-3.5:1. mixing, and then adding a water-soluble nonionic surfactant whose mass is 10-30% of the mass of copper nanowires to the mixing system, and f...

specific Embodiment 3

[0029] Specific embodiment three, please refer to figure 1 , a preparation method of elastic conductive paste, the steps are:

[0030] (1) First, carry out ligand exchange treatment on the surface of gold nanowires with an aspect ratio of 100-5000:1, so that the surface is covered with a layer of non-polar groups, and then the gold nanowires are coated with 20-60wt% by weight Disperse in a non-polar solvent and make a stable dispersion for use;

[0031] (2) dissolving the elastic polymer in a non-polar solvent, according to the polymer solution of 10-50wt% by weight;

[0032] (3) The dispersion liquid prepared in step (1) and the polymer solution prepared in step (2) are mechanically prepared according to the mass ratio of the gold nanowires in the dispersion liquid to the elastic polymer in the polymer solution being 1.5-3.5:1. mixing, then adding a water-soluble nonionic surfactant whose mass is 10-30% of the mass of the gold nanowires to the mixing system, and finally mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com