Method for improving light emitting performance by automatically injecting Si ions to silicon-based material

A silicon-based material, ion implantation technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unpublished reports, only observable at low temperature, and low fluorescence annihilation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

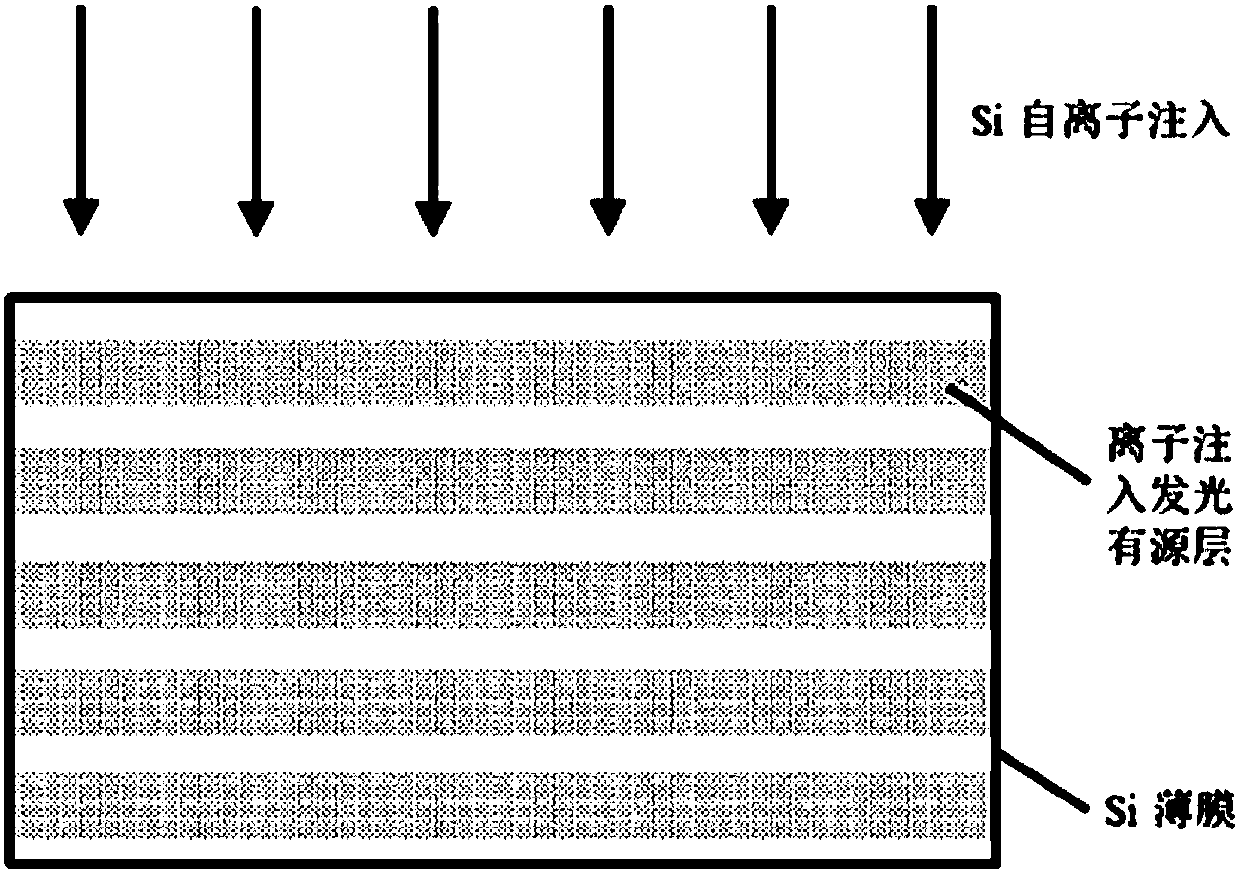

[0017] In this embodiment, Si+ is self-injected into the silicon film on the insulating layer, that is, the SOI (Silicon on insulator) substrate. The thickness of the top silicon layer is 210nm, the purity is ~99.999%, the resistivity is ~10Ω·cm, [100] crystal orientation, p type single crystal. The middle layer is 340nm thick SiO2, and the bottom layer is p-type single crystal Si with a thickness of 675 µm.

[0018] Step 1: Surface-treat the SOI substrate with Shiraki standard cleaning.

[0019] Step 2: Send the SOI substrate into the vacuum implantation chamber of the ion implanter equipment. Use an ion implanter to self-implant Si+ into the top silicon film of SOI three times. The first implantation energy is 110keV, the second implantation energy is 80keV, the third implantation energy is 50keV, and each implantation dose is 1×1014cm-2 . The included angle between the ion beam and the surface normal of the silicon thin film layer is 7°, and the whole implantation proces...

Embodiment 2

[0023] Step 1 is the same as in Example 1.

[0024] The difference between step 2 and embodiment 1 is that Si+ is self-implanted into SOI top layer silicon three times with an ion implanter, and the implantation dose is 1×1013 cm-2 each time.

[0025] The difference between step 3 and embodiment 1 is that a rapid thermal annealing furnace is used to anneal the SOI substrate after ion implantation, the annealing time is 60s, and the annealing temperature is 300°C.

Embodiment 3

[0027] In this embodiment, a p-type [100] oriented single-crystal Si substrate is used, with a thickness of 675 μm, a purity of ~99.999%, and a resistivity of ~10Ω·cm.

[0028] Step 1: Surface-treat the p-type Si substrate with Shiraki standard cleaning.

[0029] Step 2: Send the Si substrate into the vacuum implantation chamber of the ion implanter equipment. Use an ion implanter to self-implant Si+ into the silicon thin film layer five times. The first implantation energy is 250keV, the second implantation energy is 200keV, the third implantation energy is 140keV, the fourth implantation energy is 100keV, and the fifth implantation energy is 100keV. The implantation energy is 60keV, and the implantation dose is 1×1016cm-2 each time. The included angle between the ion beam and the surface normal of the silicon thin film layer is 7°, and the whole implantation process is carried out under vacuum and room temperature.

[0030] Step 3: Perform conventional annealing on the imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com