Automatic mortar distributor for prefabricating interlocking blocks

An interlocking block and ash machine technology, applied in the direction of manufacturing tools, supply devices, etc., can solve the problems of large amount of manual ash separation, many hidden safety hazards and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

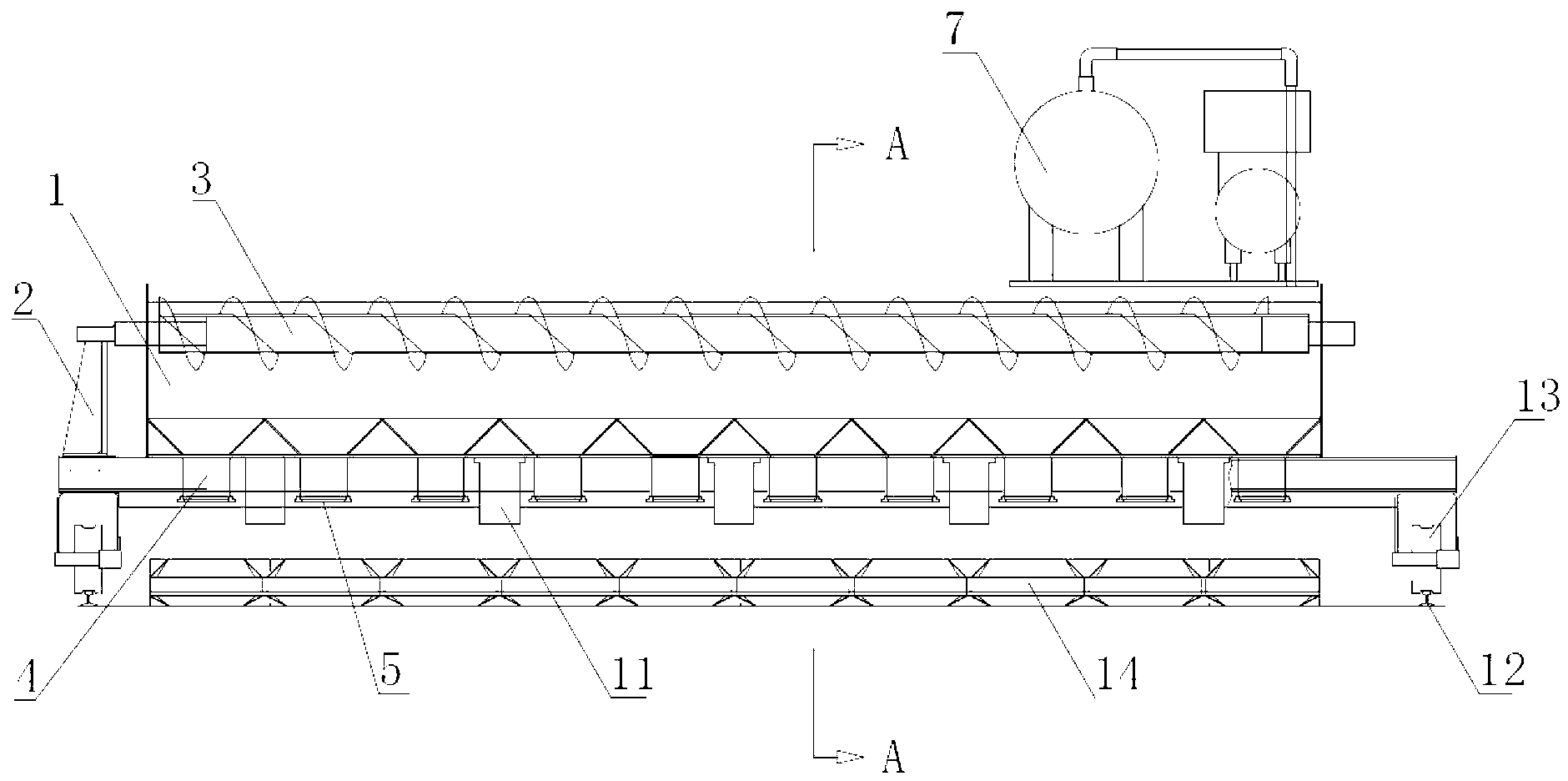

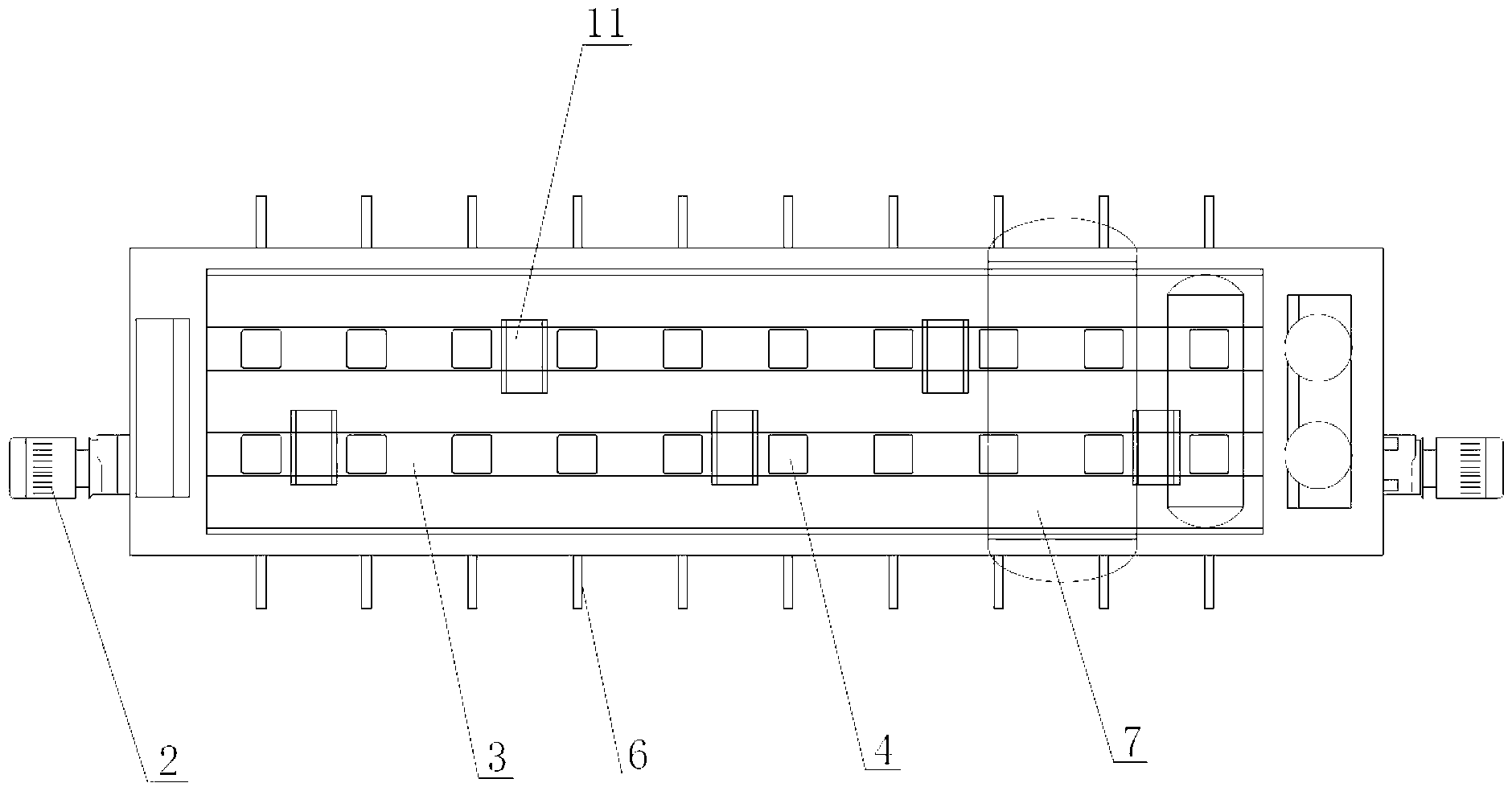

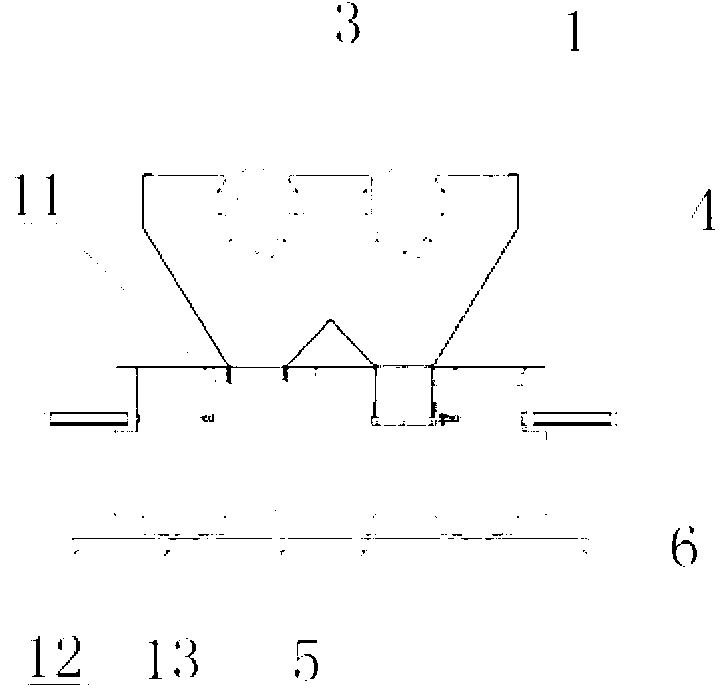

[0023] like figure 1 , figure 2 and image 3 As shown, the interlocking block prefabricated automatic ash separator of the present invention comprises a hopper 1, two variable-diameter and variable-pitch helical blades 3 driven by a motor 2 are arranged in the hopper 1, and a discharge port 4 is provided below the hopper 1. The material openings 4 are divided into two rows, 10 in each row, and the lower ash rams 5 that can be opened and closed are set. The rams 5 are controlled by the pneumatic system control system. The pneumatic system control system includes a cylinder 6 connected to the ram 5 and The air compressor 7 connected to the cylinder 6, the connection between the cylinder 6 and the air compressor 7 can adjust the ash lowering time and position, and realize the electronic control system of fixed point and quantitative ash separation. Pulse wall cleaners 11 are arranged at intervals beside the discharge port 4 . The wheels 13 matched with the track 12 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com