Preparation method of lanthanum manganese oxide/strontium iridate heterojunction film

A thin film preparation, strontium iridate technology, applied in semiconductor/solid-state device manufacturing, vacuum evaporation coating, coating and other directions, can solve the difficulty of preparing lanthanum manganese oxide/strontium iridate heterojunction, cumbersome and uncontrollable magnetic regulation, etc. problem, to achieve the effect of fast and effective preparation, low production cost and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content of the present invention, the present invention will be described in detail with reference to the accompanying drawings and specific embodiments.

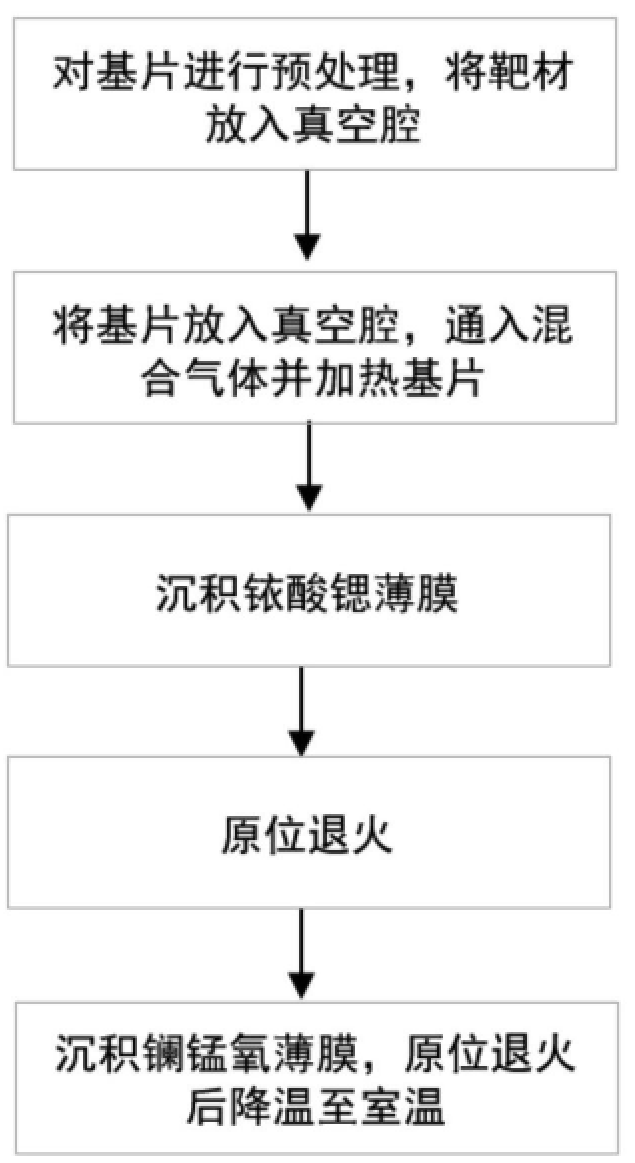

[0028] figure 1 This is a flow chart of the method of the present invention. The preparation process is: pretreating the strontium titanate substrate. The method adopted in this embodiment is as follows: first, at room temperature, the strontium titanate substrate is separately dissolved in acetone and anhydrous ethanol. After ultrasonic cleaning for 5 min, the strontium titanate substrates were ultrasonically cleaned in deionized water and aqua regia for 20 min at 70 °C, respectively. Finally, the treated substrates were annealed at 1000 °C for 2 h in an oxygen atmosphere. Prepare lanthanum manganese oxide and strontium iridate targets respectively, and place the targets in a vacuum chamber for later use.

[0029] Then put the processed substrate into the vacuum chamber, and set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com