A kind of low SFD magnetic recording material and preparation method thereof

A magnetic recording and oxide technology, applied in the field of magnetic information materials, can solve problems such as restricting applications, and achieve the effects of ensuring magnetic properties, refining particle size, and improving uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

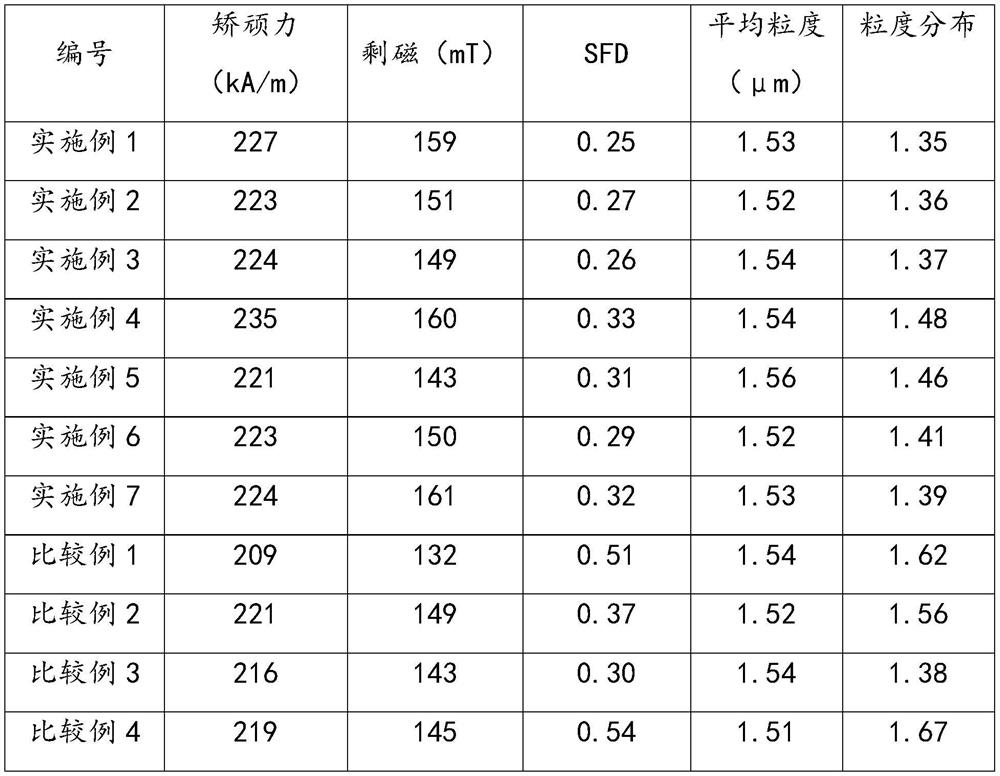

Examples

preparation example Construction

[0058]The present invention also provides a method of preparing a magnetic recording material of the low SFD, comprising the steps of:

[0059]The raw materials were blended, densely treated, 1-4 h at 1-4h at 1000-1200 ° C, rough crushed, and refurbished from 920-1000 ° C for 1-4 h, and the magnetic recording material was obtained.

[0060]In a preferred embodiment of the invention, the gradient is warmed for 1-4 h at 1000-1200 ° C gradient. More preferably, at 1000-1050 ° C pre-fertilized 0.5-1 to 1060-1100 ° C, the temperature is 10.50 to 1200 ° C. 0.5-2 h.

[0061]In a preferred embodiment of the invention, the dense process comprises: dense processing of 30-90s using a mine mill.

[0062]In a preferred embodiment of the invention, the ball of the ball is from 50 to 500 μm.

[0063]In a preferred embodiment of the invention, the crude crushing to a particle size of 2.0 to 2. μm after pre-feave.

[0064]In a preferred embodiment of the invention, the fine milling method comprises: wet fine milling ...

Embodiment 1

[0067]The method of preparing the magnetic recording material according to the present embodiment, the steps are as follows:

[0068](1) According to the weight of the weight, 135 parts of the iron (Tangshan Iron and Steel Group), 15 parts of carbonate, 7 copies of bicarbonate, niomethorium oxide, 0.7 copies of niobium oxide, 1.2 parts of oxide, titanium oxide 1.2 parts 1.6 parts of cobalt oxide, 1.6 parts of zirconia, 1.6 parts of nickel oxide, 2 parts of nicodium oxide, mixed in a mine machine, after dense treatment of 60s, water, the ball is 200 μm;

[0069](2) Pre-war at 1020 ° C in 1020 ° C for 1 h at 1020 ° C, and then warmed to 1 h at 1180 ° C; after the end, the ball mill is first carried out to the average particle size 2.0μm;

[0070](3) Place the material obtained in step (2) is placed in the ball mill, and the fine mill is 1.5 μm;

[0071](4) The material obtained in step (3) was treated with 2 h at 980 ° C, and then dispersed using a high speed pulverizer to obtain the magnetic rec...

Embodiment 2

[0073]The present embodiment refers to the preparation method of Example 1. The difference is only that the raw material of the present embodiment is 135 parts of the iron red (Tangshan Iron and Steel Group), 18 parts of Barium carbonate, 8 copies of carbonate, manganese oxide 1.5 0.7 parts of niobium oxide, 1.2 parts of oxide, 1.2 parts of titanium oxide, 1.6 parts of cobalt oxide, 1.6 parts of zirconia, 1.6 parts of nickel oxide, and 2 trioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com