A kind of cobalt-based multilayer film and preparation method thereof

A multi-layer film, cobalt-based technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problem of damage to perpendicular magnetic anisotropy, achieve increased range and controllability, and simple process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

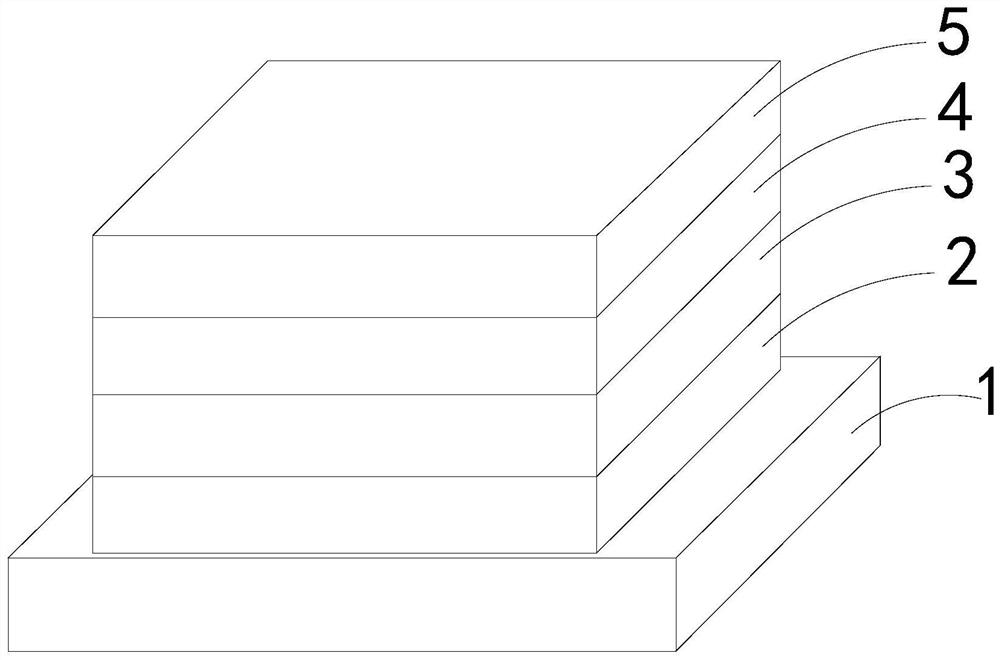

[0034] Based on the same inventive concept, the present application also provides a method for preparing a cobalt-based multilayer film, comprising the following steps:

[0035] S1. Provide a base;

[0036] S2. Prepare a first covering layer on one side of the substrate;

[0037] S3, preparing a nitrogen-doped tungsten layer on the side of the first covering layer away from the substrate;

[0038] S4, preparing a Co-based soft magnetic layer on the side of the nitrogen-doped tungsten layer away from the substrate;

[0039] S5, preparing a second covering layer on the side of the base of the Co-based soft magnetic layer.

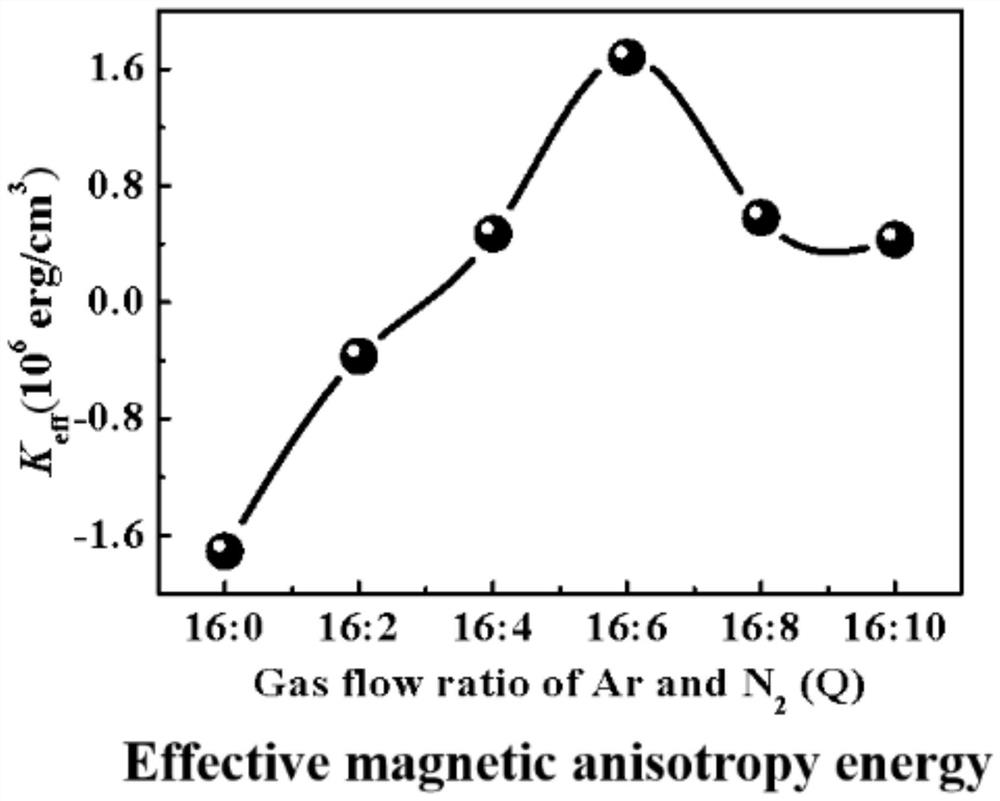

[0040] In some embodiments, the nitrogen-doped tungsten layer is prepared by magnetron sputtering method in S3, wherein the magnetron sputtering method is specifically: using argon as the sputtering gas, using W as the sputtering target, The nitrogen gas is fed into the target at the same time, and the nitrogen gas flow is stopped after the deposition is c...

Embodiment 1

[0052] A cobalt-based multilayer film, which includes a Si substrate and a first covering layer, a nitrogen-doped tungsten layer, a Co-based soft magnetic layer, and a second covering layer sequentially positioned on one side of the Si substrate, wherein the material of the first covering layer is Ta, the thickness of the first covering layer is 2nm, the thickness of the nitrogen-doped tungsten layer is 3nm, the material of the Co-based soft magnetic layer is Co, the thickness of the Co-based soft magnetic layer is 1nm, and the material of the second covering layer is Pt , the thickness of the second covering layer is 2nm.

[0053] Specifically, the preparation method of the cobalt-based multilayer film comprises the following steps:

[0054] S1, providing a Si substrate;

[0055] S2. Using Ta as the target, Ta is prepared on one side of the Si substrate by magnetron sputtering, which is the first covering layer; wherein, the sputtering power of the Ta target is 120W, and the...

Embodiment 2

[0060] The structure and preparation method of the cobalt-based multilayer film provided in the embodiment of the present application are the same as in the embodiment 1, except that the flow ratio of nitrogen gas and argon gas is 4:16.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com