Comprehensive utilization method of biomass raw material

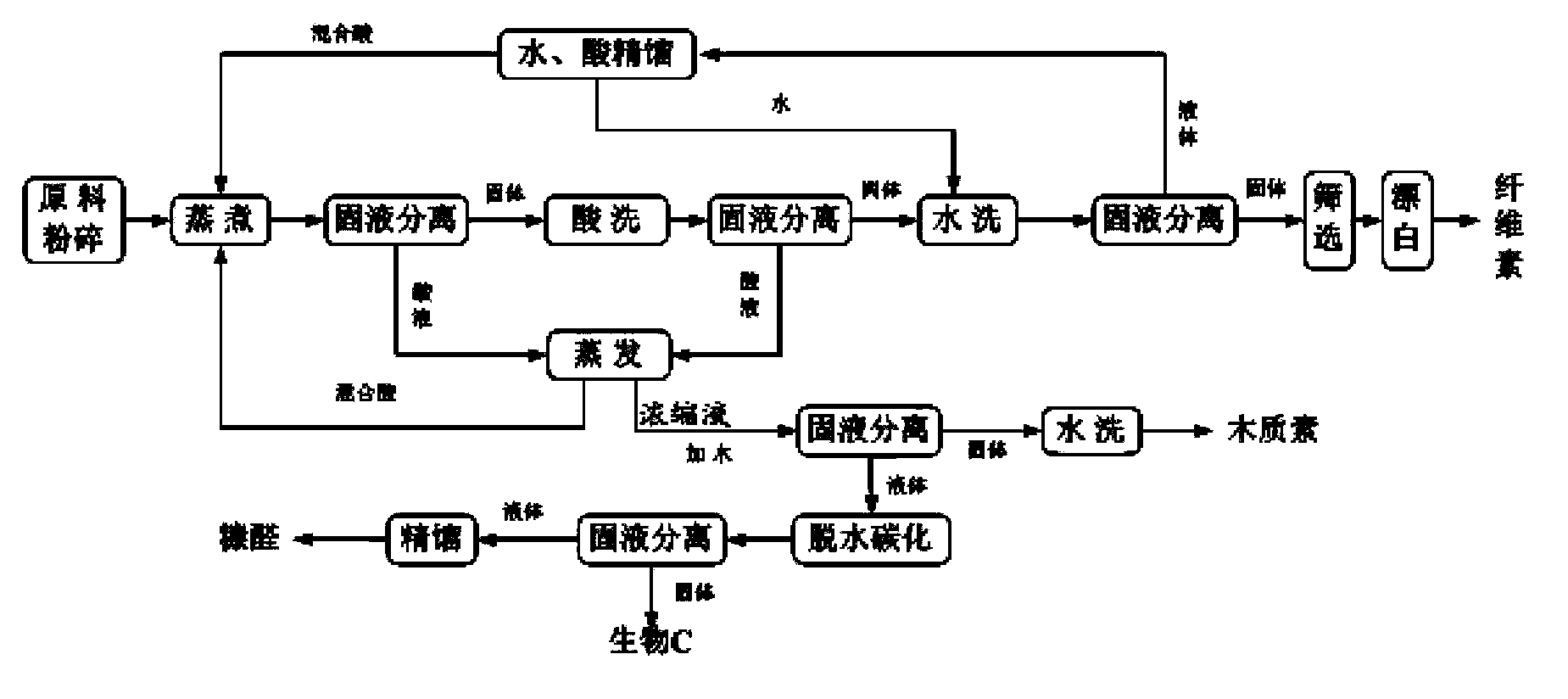

A biomass raw material and process technology, which is applied in the preparation/purification of carbon, pulping with organic solvents, non-woody plant/crop pulp, etc., can solve the problems of low component yield and low purity, and achieve extraction efficiency High, reduce damage, shorten the effect of cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this example, the biomass raw material is reed (mass component composition: 49.5% cellulose, 22.7% hemicellulose content, 18.9% lignin), first crushed, washed with water, dedusted and crushed to a particle size of 2cm ~10cm. The present embodiment comprises the following steps from the comprehensive utilization process of the biomass raw material:

[0063] (1) After the biomass raw material is pulverized and pretreated, the organic acid solution of formic acid and acetic acid with a total acid concentration of 60% is used to cook the treated biomass raw material. The mass of acetic acid and formic acid in the organic acid solution of this embodiment The ratio is 1:1, and 3% hydrogen peroxide (H 2 o 2) as a catalyst, control the reaction temperature at 125°C, react for 40 minutes, and have a solid-liquid mass ratio of 1:10, and conduct the first solid-liquid separation of the obtained reaction liquid;

[0064] (2) The solid obtained from the first solid-liquid sepa...

Embodiment 2

[0078] In this embodiment, the rice straw (mass component composition: 35.8% cellulose, 28.6% hemicellulose, and 14.3% lignin) was first crushed to a particle size of 2 cm to 10 cm. The present embodiment comprises the following steps from the comprehensive utilization technique of described rice straw:

[0079] (1) After the rice straw is pulverized and pretreated, the treated rice straw is cooked using an organic acid solution with a total acid concentration of 65% formic acid and acetic acid. The mass ratio of acetic acid to formic acid in the organic acid solution of this embodiment is 1: 6, and add before adding the straw raw material and account for 4% hydrogen peroxide (H 2 o 2 ) as a catalyst, control the reaction temperature at 130°C, react for 10 minutes, the solid-liquid mass ratio is 1:30, and conduct the first solid-liquid separation of the obtained reaction liquid;

[0080] (2) The solid obtained from the first solid-liquid separation is added to an organic aci...

Embodiment 3

[0094] In this embodiment, the biomass raw material is bamboo chips (mass composition: 47.3% cellulose, 24.6% hemicellulose, 25.8% lignin), first crushed, washed with water to remove dust and crushed to a particle size of 2cm~10cm. The comprehensive utilization technology of bamboo chip described in the present embodiment, comprises the steps:

[0095] (1) After the bamboo slices are pulverized and pretreated, the treated bamboo slices are cooked with an organic acid solution with a total acid concentration of 70% formic acid and acetic acid. The mass ratio of acetic acid to formic acid in the organic acid solution of this embodiment is 1:12, and add 6% hydrogen peroxide (H 2 o 2 ) as a catalyst, the reaction temperature is controlled at 80°C, and the reaction is carried out for 90 minutes. The solid-liquid mass ratio of the organic acid liquid and the bamboo chip raw material is 1:5, and the obtained reaction liquid is subjected to solid-liquid separation for the first time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com