Method for plating thin film on inner wall of slender pipeline

A pipeline, slender technology, applied in the field of vacuum coating, can solve the problems such as the inability to realize vacuum coating technology, and achieve the effects of good uniformity, strong process controllability and simple coating method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

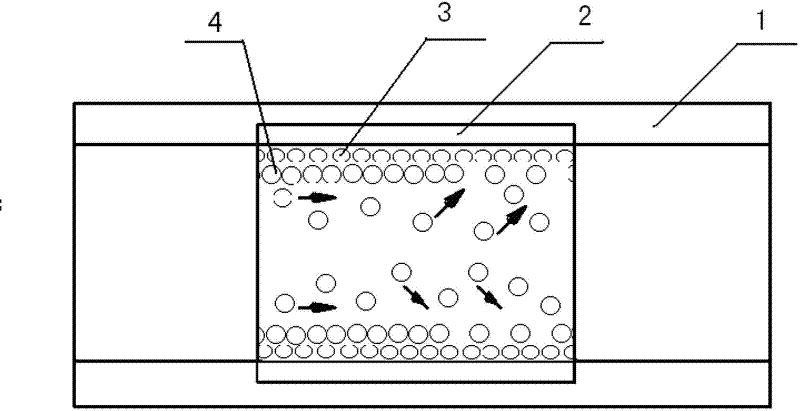

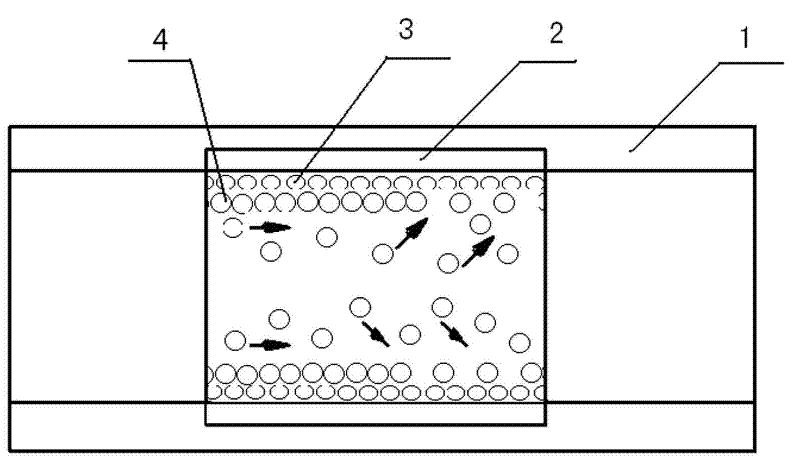

[0022] Example 1: Take the reaction of trimethylaluminum and water vapor to generate aluminum oxide as an example.

[0023] (1) Place the slender pipe to be coated in the reaction chamber (the inner wall of the reaction chamber should match the outer wall of the pipe, it is best to embed the slender pipe into the inner wall of the reaction chamber so that the inner wall of the pipe and the inner wall of the reaction chamber on the same side. See attached figure 1 , where 1 is the reaction chamber, 2 is the pipeline, 3 is the reaction precursor A, 4 is the reaction precursor B), and the reaction chamber is evacuated to 1×10 -3 Pa.

[0024] (2) Inject gas-phase reaction precursor A trimethylaluminum (TMA) into the reaction chamber in a pulse form, with a flow rate of 15 sccm and a duration of 5 s, to form a single adsorption layer by chemical adsorption on the inner surface of the pipe to be coated.

[0025] (3) Argon (Ar) gas is introduced into the reaction chamber at a flow ...

Embodiment 2

[0029] Example 2: Take the reaction of trimethylaluminum and hydrogen to generate aluminum as an example.

[0030] (1) Place the pipe to be coated in the reaction chamber (the way the pipe is placed in the reaction chamber is copper example 1), and evacuate the reaction chamber to 2×10 -3 Pa.

[0031] (2) Inject the first gas-phase reaction precursor A trimethylaluminum (TMA) into the reaction chamber in pulse form, with a flow rate of 18 sccm and a duration of 6 s, to form a single adsorption layer by chemical adsorption on the inner surface of the pipe to be coated;

[0032] (3) Argon (Ar) gas was introduced into the reaction chamber at a flow rate of 25 sccm for 15 s to remove the excess unadsorbed precursor trimethylaluminum.

[0033] (4) The second gas-phase reaction precursor B hydrogen (H 2 ), the flow rate is 15sccm, and the duration is 8s. It reacts with the precursor A trimethylaluminum (TMA) to form a monoatomic layer on the inner surface of the pipe to be coated;...

Embodiment 3

[0036] Embodiment 3: Take the reaction of titanium tetrachloride and ammonia gas to generate titanium nitride as an example.

[0037] (1) Place the pipe to be coated in the reaction chamber (the way the pipe is placed in the reaction chamber is copper example 1), and evacuate the reaction chamber to 1×10 -3 Pa.

[0038] (2) Inject the first gas phase reaction precursor A titanium tetrachloride (TiCl 4 ), the flow rate is 20sccm, and the duration is 5s. A single adsorption layer is formed by chemical adsorption on the inner surface of the pipe to be coated.

[0039] (3) Argon gas (Ar) was introduced into the reaction chamber at a flow rate of 20 sccm for 10 s to remove the excess unadsorbed precursor A titanium tetrachloride.

[0040] (4) Inject the second gas-phase reaction precursor B ammonia (NH 3 ), and react with the precursor A titanium tetrachloride adsorbed on the inner wall of the pipe to form a monoatomic layer of titanium nitride on the inner surface of the pipe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com