Supporting or non-supporting type transition metal @h-BN core-shell nanostructure preparation method

A nanostructure and transition metal technology, applied in metal processing equipment, nanotechnology, nanotechnology, etc., can solve the problems of complex preparation process, expensive raw materials, poor repeatability, etc., and achieve easy control of reaction conditions, easy scale-up production, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

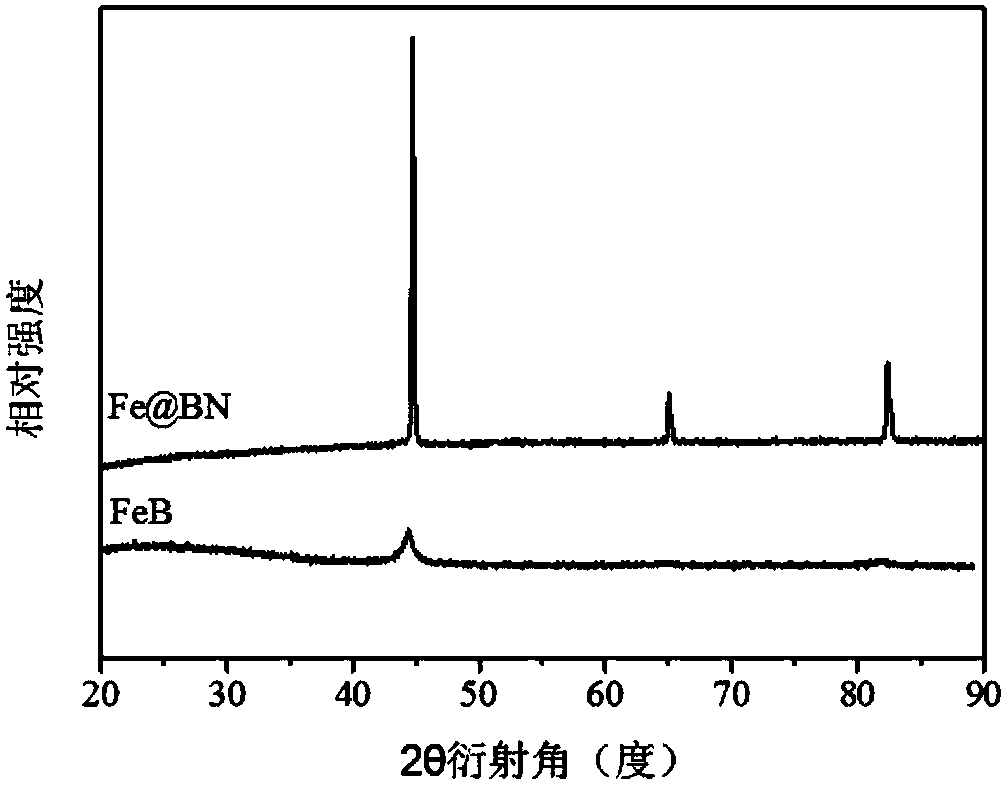

[0044] Preparation of iron-boron alloy (FeB): Dissolve 0.6977g of ferrous sulfate heptahydrate in 25mL of deionized water under the protection of argon and stir in an ice bath; dissolve 0.0412g of sodium hydroxide in 10mL of deionized water, and after cooling , then add 0.5362g of potassium borohydride to dissolve; add the potassium borohydride solution dropwise to the ferrous sulfate solution, after the dropwise addition, continue to stir for 0.5h, use a magnet for magnetic separation, wash with water until neutral, wash with ethanol three times, vacuum 40 Dry at ℃ for 8 hours to obtain iron-boron alloy (FeB).

[0045] Raise the temperature of the FeB alloy to 500°C at 5°C / min in an ammonia atmosphere, keep it for 2h, continue to heat it up to 850°C at 5°C / min in an ammonia atmosphere, keep it for 1h, and cool it down to room temperature in an argon atmosphere to obtain Fe@h -BN core-shell nanomaterials.

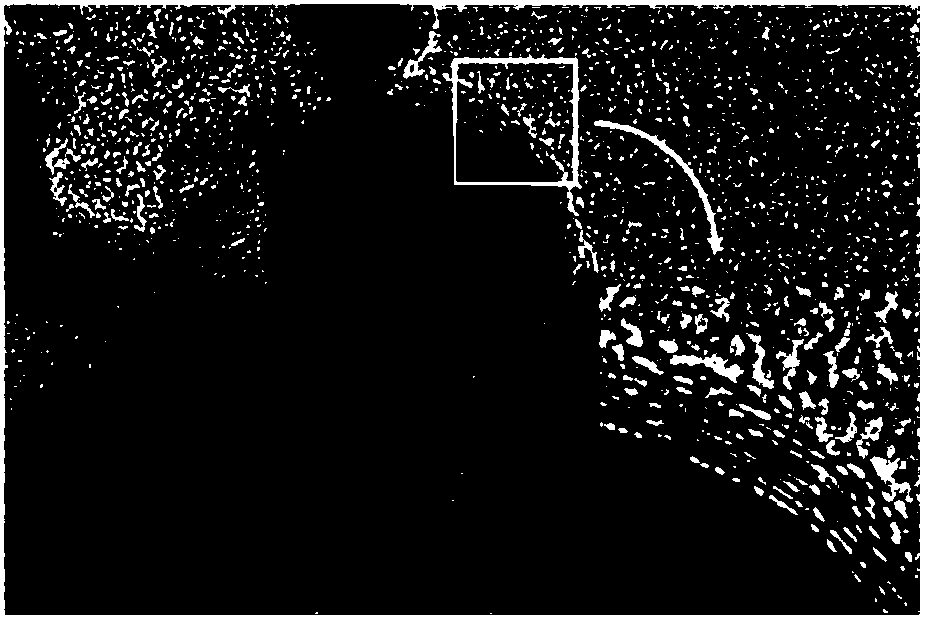

[0046] figure 1 It is a high-resolution electron microscope photo o...

Embodiment 2

[0052] Pipetting concentration is the ruthenium trichloride RuCl of 0.0964mol / L 3 20mL aqueous solution was placed on a stirring table at room temperature and stirred; 0.0330g sodium hydroxide was dissolved in 8mL deionized water, after cooling, 0.4290g potassium borohydride was added to dissolve; potassium borohydride solution was added dropwise to ruthenium trichloride solution After the dropwise addition, continue to stir for 2h, separate by suction filtration, wash with water until neutral, wash with ethanol three times, and dry at 60°C for 8h in vacuum to obtain ruthenium boron alloy (RuB).

[0053] The RuB alloy was heated up to 500°C at 5°C / min in an ammonia atmosphere, kept for 4h, continued to be heated at 5°C / min in ammonia gas to 700°C, kept for 3h, and dropped to room temperature in an argon atmosphere to obtain Ru@h-BN Core-shell nanomaterials.

[0054] Figure 6 It is a transmission electron microscope photo of the Ru@h-BN sample. It can be seen that the nanopa...

Embodiment 3

[0057] Pipetting concentration is the ruthenium trichloride RuCl of 0.0964mol / L 3 5mL aqueous solution was placed on a stirring table at room temperature and stirred, and 1.0091g of carrier XC-72 was weighed in RuCl 3 Add 100mL of deionized water to the solution, and stir evenly after ultrasonication; dissolve 0.0083g of sodium hydroxide in 4mL of deionized water, and after cooling, add 0.1134g of potassium borohydride to dissolve; add the potassium borohydride solution dropwise to the trichloro In the ruthenium solution, after the dropwise addition, continue to stir for 2 hours, separate by suction filtration, wash with water until neutral, wash with ethanol three times, and dry in vacuum at 30°C for 14 hours to obtain a ruthenium-boron alloy (5% RuB / C) supported by XC-72 .

[0058] The temperature of 5% RuB / C alloy was raised to 500°C at 5°C / min in ammonia atmosphere, kept for 2h, continued to be heated at 5°C / min in ammonia gas to 600°C, kept for 4h, and cooled to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com