Core-shell composite positive electrode material coated with mixed polymer, its preparation method and application in lithium ion battery

A technology of composite positive electrode material and mixed polymer, which is applied in batteries, battery electrodes, secondary batteries, etc., can solve the problems of high nickel positive electrode material performance and other problems, achieve good physical compatibility, reduce internal resistance, and simple coating method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

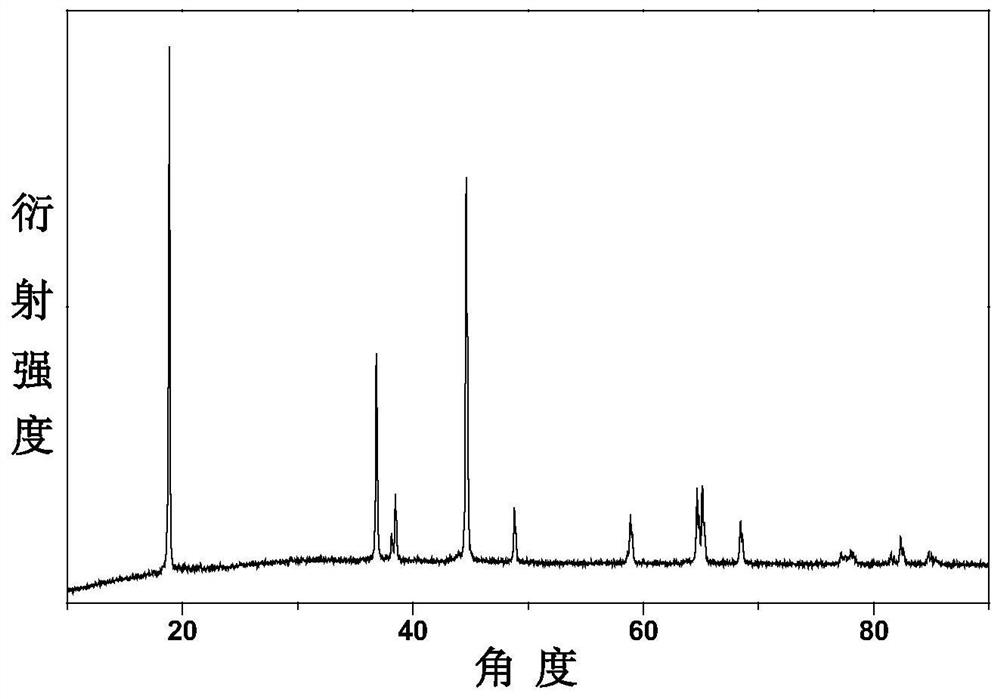

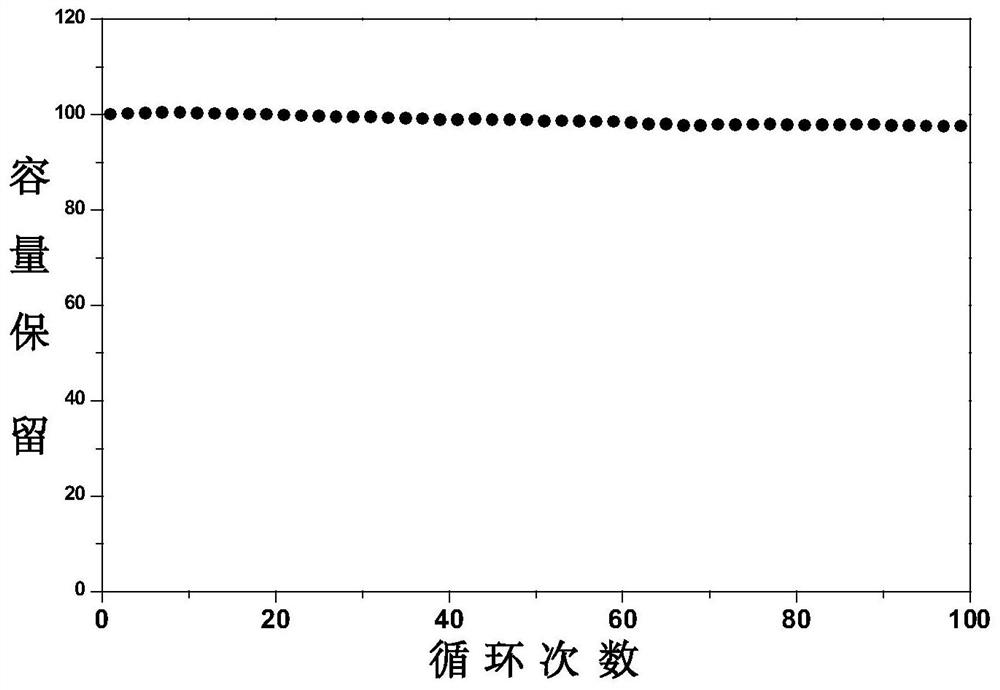

[0050] This embodiment provides a core-shell composite positive electrode material coated with a mixed polymer. The composite positive electrode material includes: an inner core of a high-nickel nickel-cobalt-aluminum positive electrode material, and a mixed polymer shell coated on the surface of the inner core. The mixed polymer shell accounts for 0.5% to 5% of the total mass of the core-shell composite positive electrode material;

[0051] The mixed polymer shell is: a shell made of a mixture of conductive polymer and organic solid electrolyte in a mass ratio of 3:7 to 7:3;

[0052] The organic solid electrolyte is a mixture of polyethylene oxide and lithium hexafluorophosphate in a mass ratio of 3:1.

[0053] Preparation:

[0054] (1) Mix polyethylene oxide and lithium hexafluorophosphate, and ball mill at a speed of 500 rpm for 2 hours to obtain a uniform polymer electrolyte mixture, which is used as mixture A;

[0055] (2) Add a silane coupling agent to the high-nickel-...

Embodiment 2

[0062] This embodiment provides a core-shell composite positive electrode material coated with a mixed polymer, and the composite positive electrode material includes: LiNi 0.6 co 0.2 Al 0.2 o 2 An inner core of the positive electrode material, and a mixed polymer shell coated on the surface of the inner core, and the mixed polymer shell accounts for 1% of the total mass of the core-shell composite positive electrode material;

[0063] The mixed polymer shell is: a shell made of a mixture of a conductive polymer and an organic solid electrolyte in a mass ratio of 3:7;

[0064] The conductive polymer is polyaniline; the organic solid electrolyte is a mixture of polyethylene oxide and lithium hexafluorophosphate at a mass ratio of 1:1.

[0065] Preparation:

[0066] (1) Mix polyethylene oxide and lithium hexafluorophosphate, and ball mill at a speed of 700 rpm for 1 hour to obtain a uniform polymer electrolyte mixture, which is used as mixture A;

[0067] (2) LiNi in lithiu...

Embodiment 3

[0071] This embodiment provides a core-shell composite positive electrode material coated with a mixed polymer, and the composite positive electrode material includes: LiNi 0.5 co 0.3 mn 0.2 o 2 An inner core of the positive electrode material, and a mixed polymer shell coated on the surface of the inner core, and the mixed polymer shell accounts for 5% of the total mass of the core-shell composite positive electrode material;

[0072] The mixed polymer shell is: a shell made of a mixture of a conductive polymer and an organic solid electrolyte at a mass ratio of 7:3;

[0073] The conductive polymer is polypyrrole; the organic solid electrolyte is a mixture of polyethylene oxide and lithium hexafluorophosphate in a mass ratio of 6:1.

[0074] Preparation:

[0075] (1) Mix polyethylene oxide and lithium hexafluorophosphate, and ball mill at a speed of 850 rpm for 1.5 hours to obtain a uniform polymer electrolyte mixture, which is used as mixture A;

[0076] (2) LiNi in lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com