Preparation method for abrasion-resistant super-hydrophobic coating

A super-hydrophobic coating and abrasion-resistant technology, which is applied to coatings, devices for coating liquid on the surface, special surfaces, etc., can solve problems such as low adhesion and poor mechanical stability, and achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

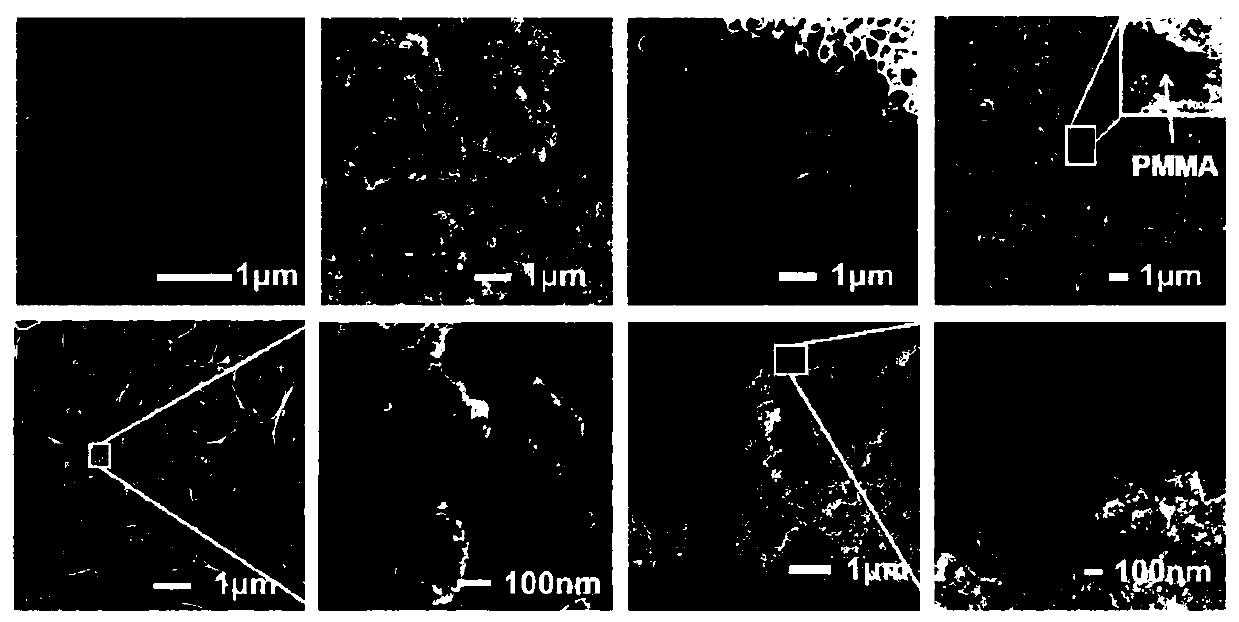

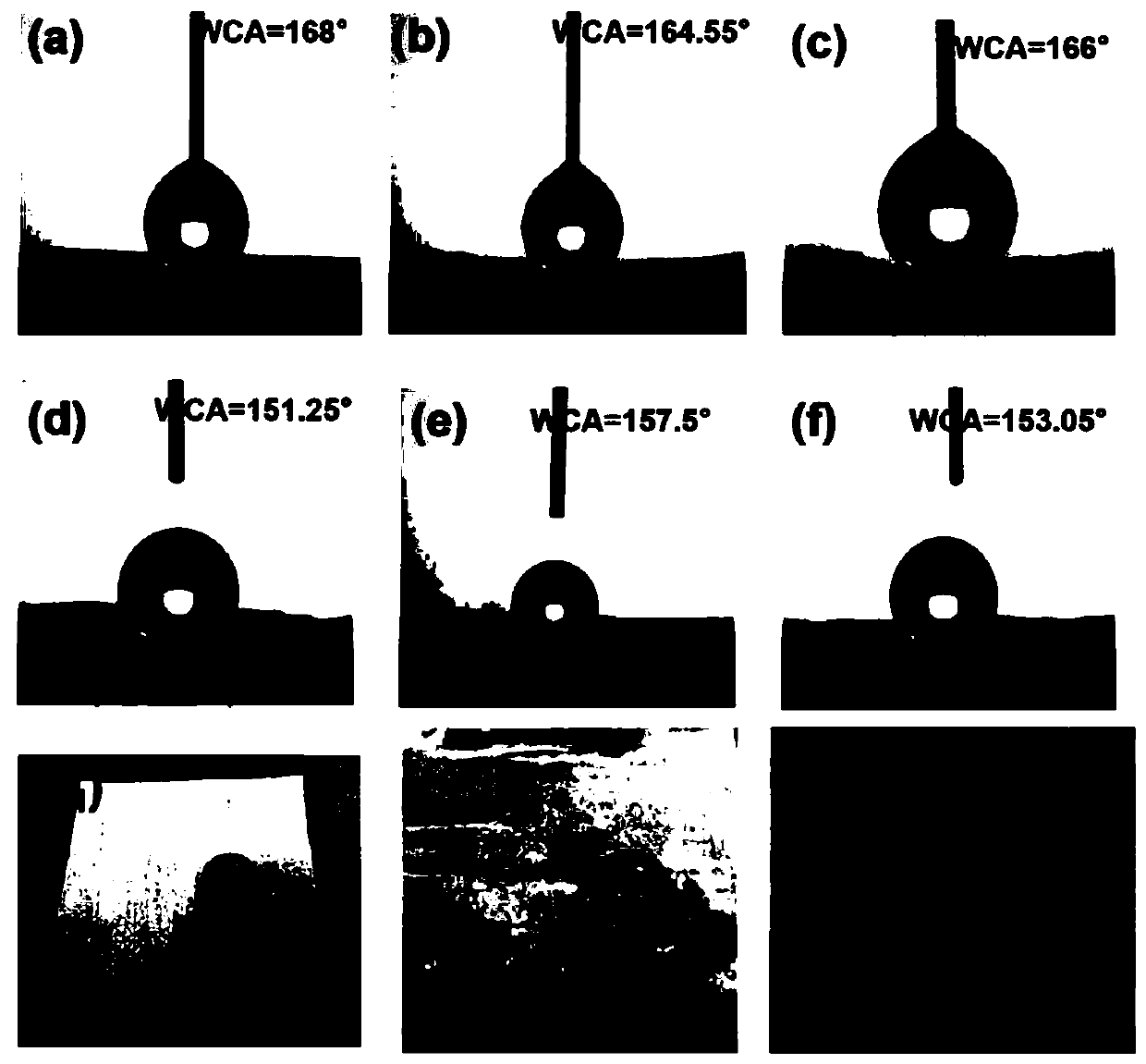

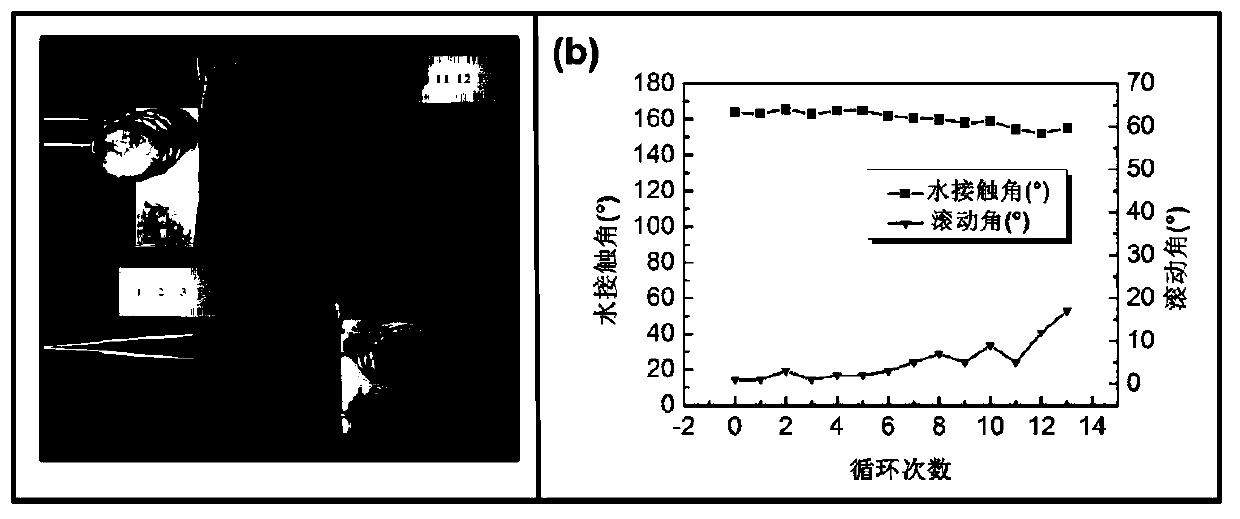

Image

Examples

Embodiment 1

[0031] (1) Preparation of solution A: Mix 25g of acrylic copolymer and 0.6g of BYK-333 and stir evenly, then add 50g of a blend solution of ethyl acetate and butyl acetate with a volume ratio of 3:1, stir for 5min, then add in sequence 0.15g adipic acid / neopentyl glycol / trimellitic anhydride copolymer, 0.15g acetyl tributyl citrate, 0.4g epoxy resin, stir at high speed for 30 minutes, add 24.7g nitrocellulose, stir at low speed for 10 minutes to obtain solution A.

[0032] (2) Modification of nano-silica particles: mix nano-silica particles with triethoxy-1H, 1H, 2H, 2H-tridecafluoro-N-octylsilane (triethoxy-1H, 1H , 2H, 2H-tridecafluoro-N-octylsilane (the mass concentration ratio of cyclohexane is 5%wt) solution was fully mixed for 2 hours, and the modified nano-silica particles were obtained after drying.

[0033] (3) Preparation of solution B: Add polymethyl methacrylate to tetrahydrofuran solution at 30°C and stir evenly. After heating to 45°C, add the modified nano-silica...

Embodiment 2

[0040] (1) Preparation of solution A: First mix 25g of acrylic copolymer and 0.6g of BYK-333 and stir evenly, then add 50g of a blend solution of ethyl acetate and butyl acetate with a volume ratio of 3:1, stir for 5 minutes and then Add 0.15 g of adipic acid / neopentyl glycol / trimellitic anhydride copolymer, 0.15 g of acetyl tributyl citrate, and 0.4 g of epoxy resin, stir at high speed for 45 minutes, add 24.7 g of nitrocellulose, and stir at low speed for 15 minutes to obtain solution A.

[0041] (2) Modification of nano-silica particles: mix nano-silica particles with triethoxy-1H, 1H, 2H, 2H-tridecafluoro-N-octylsilane (triethoxy-1H, 1H , 2H,2H-tridecafluoro-N-octylsilane (the mass concentration ratio of cyclohexane is 6%wt) solution is fully mixed for 2-4 hours, and the modified nano-silica particles are obtained after drying.

[0042] (3) Preparation of solution B: Add polymethyl methacrylate to tetrahydrofuran solution at 30°C and stir evenly. After heating to 45°C, add...

Embodiment 3

[0047] (1) Preparation of solution A: First mix 25g of acrylic copolymer and 0.6g of BYK-333 and stir evenly, then add 50g of a blend solution of ethyl acetate and butyl acetate with a volume ratio of 3:1, stir for 5 minutes and then Add 0.15 g of adipic acid / neopentyl glycol / trimellitic anhydride copolymer, 0.15 g of acetyl tributyl citrate, and 0.4 g of epoxy resin, stir at high speed for 30 minutes, add 24.7 g of nitrocellulose, and stir at low speed for 15 minutes to obtain solution A.

[0048] (2) Modification of nano-silica particles: mix nano-silica particles with triethoxy-1H, 1H, 2H, 2H-tridecafluoro-N-octylsilane (triethoxy-1H, 1H , 2H, 2H-tridecafluoro-N-octylsilane (the mass concentration ratio of cyclohexane is 6%wt) solution was fully mixed for 3 hours, and dried to obtain modified nano-silica particles.

[0049] (3) Preparation of solution B: Add polymethyl methacrylate into the tetrahydrofuran solution at 25°C-30°C and stir evenly. After heating to 40°C, add th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com