Method for preparing anti-icing self-repaired coating

An anti-icing and self-healing technology, applied in coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve problems such as difficulties, substrate processing difficulties, poor wettability, etc., and achieves simple coating methods and low preparation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Coatings can be applied to a wide range of substrates

[0027] (1) Preparation of mixed emulsion: Weigh 0.5g of micron calcium carbonate particles, 0.25g of hydrophobic nano-silica particles, 0.7g of polydimethylsiloxane, 4g of ethyl acetate in a container and mix them magnetically for 30-40min stand-by;

[0028] (2) Cleaning of the substrate: the composite plastic (the composite plastic is FR-4 epoxy glass fiber board, the company is Hongyuntong Plastic Material Co., Ltd.), glass slides (glass slides) are cleaned by washing powder and ultrasonic cleaning in sequence. , Ordinary water cleaning, ultrasonic cleaning, acetone cleaning, deionized water cleaning and drying for later use;

[0029] (3) Preparation of the mixed coating of calcium carbonate and silicon dioxide: immerse the cleaned substrate in the emulsion of (1), soak for 10 minutes, take it out and dry it, and then bake it at 130°C for 60 minutes;

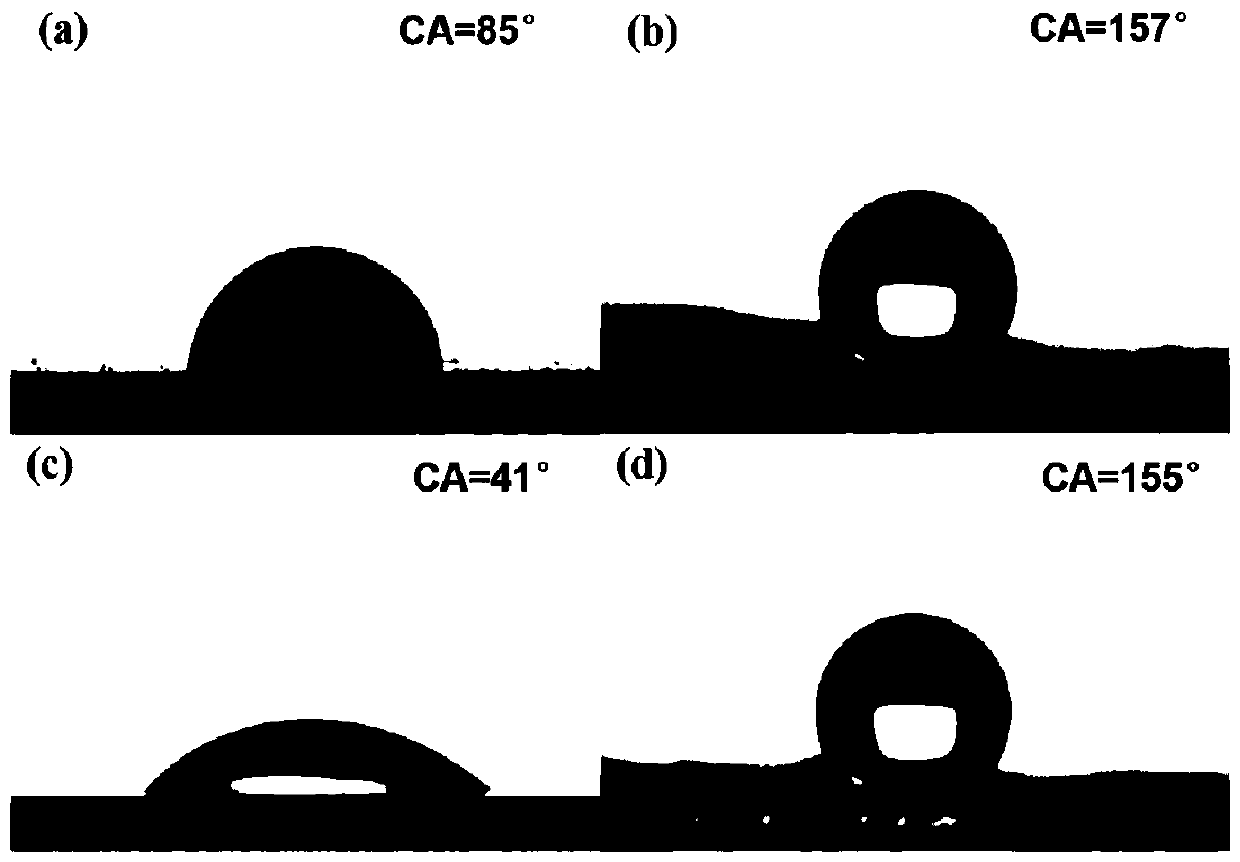

[0030] (4) Preparation of super-hydrophobic coating; soak t...

Embodiment 2

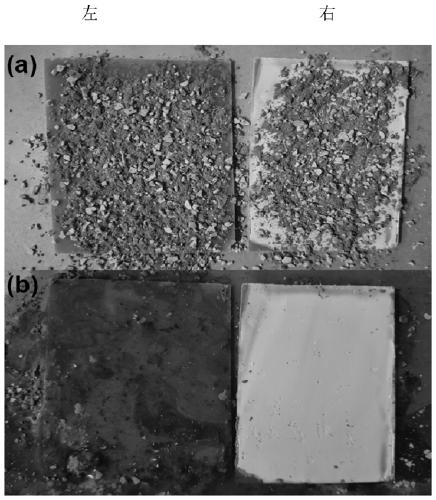

[0034] Self-cleaning of coatings on composite plastic substrates

[0035] (1) Preparation of mixed emulsion: Weigh 1g of micron calcium carbonate particles, 0.25g of hydrophobic nano-silica particles, 1g of polydimethylsiloxane, and 4.5g of ethyl acetate in a beaker and mix them magnetically for 30-40min. use;

[0036] (2) Cleaning of the substrate: The composite plastic (the composite plastic is FR-4 epoxy glass fiber board, the company is Hongyuntong Plastic Material Co., Ltd.) is washed by washing powder, ultrasonic cleaning, ordinary water cleaning, ultrasonic cleaning, Wash with acetone and deionized water and dry for later use

[0037] (3) Preparation of the mixed coating of calcium carbonate and silicon dioxide: immerse the cleaned substrate in the emulsion of (1), soak for 10 minutes, take it out and dry it, and then bake it at 120°C for 50 minutes;

[0038] (4) Preparation of anti-icing coating; soak the dried sample in dilute hydrochloric acid for 5-10 minutes, rinse...

Embodiment 3

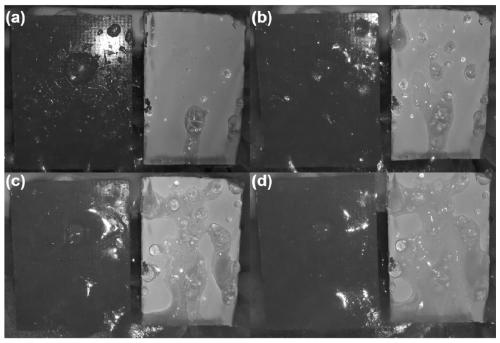

[0042] Anti-icing of Composite Plastic Substrate Coating

[0043] (1) Preparation of mixed emulsion: Weigh 1g of micron calcium carbonate particles, 0.5g of hydrophobic nano-silica particles, 1g of polydimethylsiloxane, and 5g of ethyl acetate in a beaker, mix them with magnetic force for 30-40min and set aside ;

[0044] (2) Cleaning of the substrate: The composite plastic (the composite plastic is FR-4 epoxy glass fiber board, the company is Hongyuntong Plastic Material Co., Ltd.) is washed in sequence by washing powder, ultrasonic cleaning, ordinary water cleaning, ultrasonic cleaning, After washing with acetone and deionized water, dry it for later use;

[0045] (3) Preparation of mixed coating: immerse the cleaned substrate in the emulsion of (1), soak for 10 minutes, take it out and dry it, and then bake it at 150°C for 30 minutes;

[0046] (4) Preparation of anti-icing coating; soak the dried sample in dilute hydrochloric acid for 5-10 minutes, rinse it with deionizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com