Injection molding wear-resisting and scratch-resisting glossy surface treatment agent for synthetic leather and preparation method thereof

A synthetic leather and surface treatment technology, applied in fiber treatment, textiles and papermaking, etc., can solve problems such as poor comprehensive treatment effect, and achieve the effect of clear color, strong crystal feeling and natural luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The injection molding wear-resistant and scratch-resistant bright surface treatment agent for synthetic leather is composed of the following raw material components: based on the total weight of the resin in parts by mass, it includes 35 parts of modified polyurethane, 10 parts of butyl ester, 20 parts of toluene, butanone 29 parts, 1.5 parts of wear-resistant and anti-scratch agent, 1.5 parts of methyl tin heat stabilizer.

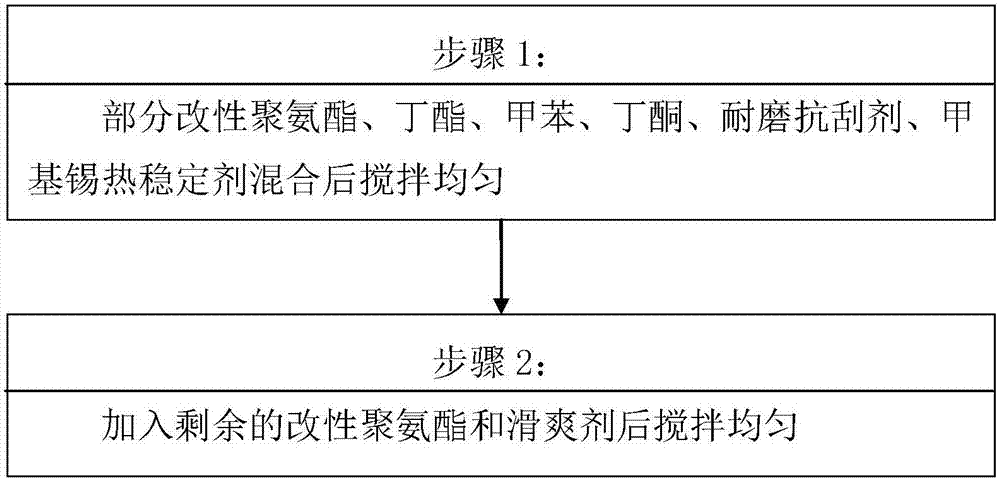

[0027] Such as figure 1 As shown, the preparation process of the injection molding wear-resistant and scratch-resistant bright surface treatment agent of the present invention is as follows:

[0028] Step 1: Stir 33 parts of partially modified polyurethane, 10 parts of butyl ester, 20 parts of toluene, 29 parts of butanone, 1.5 parts of wear-resistant and anti-scratch agent, and 1.5 parts of methyl tin heat stabilizer according to the formula to obtain a mixture;

[0029] Step 2: Add 2 parts of the remaining modified polyurethane to the mixture ob...

Embodiment 2

[0032] The injection molding wear-resistant and scratch-resistant bright surface treatment agent for synthetic leather is composed of the following raw material components: based on the total weight of the resin in parts by mass, it contains 38 parts of modified polyurethane, 12 parts of butyl ester, 21 parts of toluene, butanone 30 parts, 2 parts of wear-resistant and anti-scratch agent, 2 parts of methyl tin heat stabilizer, 1 part of slip agent.

[0033] Such as figure 1 As shown, the preparation process of the injection molding wear-resistant and scratch-resistant bright surface treatment agent of the present invention is as follows:

[0034] Step 1: According to the formula, 33 parts of partially modified polyurethane, 12 parts of butyl ester, 21 parts of toluene, 30 parts of methyl ethyl ketone, 2 parts of wear-resistant and anti-scratch agent, and 2 parts of methyl tin heat stabilizer were stirred evenly to obtain a mixture;

[0035] Step 2: Add 5 parts of the remainin...

Embodiment 3

[0038] As the most optimal embodiment, the injection molding wear-resistant and scratch-resistant bright surface treatment agent for synthetic leather consists of the following raw material components: based on the total weight of the resin in parts by mass, it includes 36 parts of modified polyurethane, 11.5 parts of butyl ester, 22 parts of toluene, 28 parts of methyl ethyl ketone, 1 part of wear-resistant and anti-scratch agent, 1 part of methyl tin heat stabilizer, and 0.5 part of slip agent.

[0039] Such as figure 1 As shown, the preparation process of the injection molding wear-resistant and scratch-resistant bright surface treatment agent of the present invention is as follows:

[0040] Step 1: Stir 31 parts of partially modified polyurethane, 11.5 parts of butyl ester, 22 parts of toluene, 28 parts of butanone, 1 part of wear-resistant and anti-scratch agent, and 1 part of methyl tin heat stabilizer according to the formula to obtain a mixture;

[0041] Step 2: Add 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com