High-brightness PET reflective film

A high-brightness, reflective technology, used in pressure-sensitive films/sheets, film/sheet-like adhesives, optics, etc. Anti-scratch performance, extended service life, improved reflective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of high brightness PET reflective film:

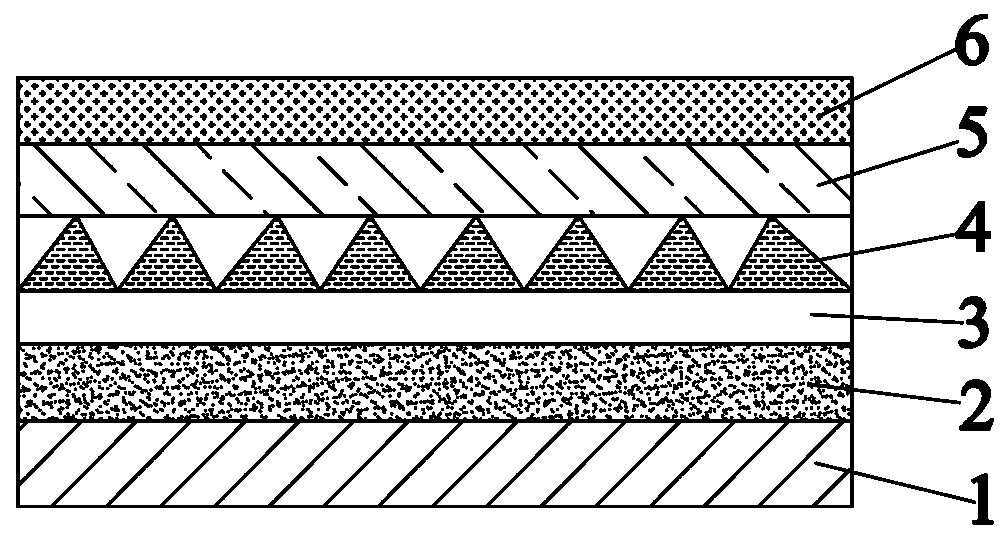

[0033] 1) Evenly disperse nano-zirconia, nano-alumina and nano-silicon dioxide into absolute ethanol through a planetary ball mill, and then compound with a high-hardness silicone resin with a mass content of 70%, and then coat it To the side of the carrier layer containing PET, and finally perform infrared curing treatment to obtain an anti-fouling, anti-scratch and anti-reflection layer;

[0034] 2) preparing a microprism structure layer by casting on the other side of the carrier layer, the microprism layer comprising several cube-corner prism array structural units;

[0035] 3) one side of the PET release layer is coated with a pressure-sensitive adhesive layer containing 2-ethylhexyl acrylate / butyl acrylate / acrylic acid copolymer, an aluminum coating is deposited on the surface of the pressure-sensitive adhesive layer, and then the microprism The layers are pressed tightly against the aluminum coating.

Embodiment 2

[0037] Preparation of high brightness PET reflective film:

[0038] 1) Evenly disperse nano-magnesium fluoride, nano-titanium dioxide and nano-alumina into absolute ethanol through a planetary ball mill, then compound with high-hardness silicone resin with a mass content of 75%, and then coat it on The side of the carrier layer containing PET is finally subjected to infrared curing treatment to obtain an anti-fouling, anti-scratch and anti-reflection layer;

[0039] 2) preparing a microprism structure layer by casting on the other side of the carrier layer, the microprism layer comprising several cube-corner prism array structural units;

[0040] 3) Coating a sensitive adhesive layer containing isooctyl acrylate / acrylic acid copolymer pressure on one side of the PET release layer, depositing a silver coating on the surface of the pressure sensitive adhesive layer, and then pressing the microprism layer tightly on the silver coating .

Embodiment 3

[0042] Preparation of high brightness PET reflective film:

[0043] 1) Nano-magnesium fluoride and nano-titanium dioxide are uniformly dispersed in absolute ethanol through a planetary ball mill, and then compounded with a high-hardness silicone resin with a mass content of 80%, and then coated on the carrier layer containing PET One side, and finally carry out infrared curing treatment to obtain anti-fouling anti-scratch anti-reflection layer;

[0044] 2) preparing a microprism structure layer by casting on the other side of the carrier layer, the microprism layer comprising several cube-corner prism array structural units;

[0045] 3) One side of the PET release layer is coated with a pressure-sensitive adhesive layer containing 2-ethylhexyl acrylate / butyl acrylate / acrylic acid copolymer and isooctyl acrylate / acrylic acid copolymer, and on the surface of the pressure-sensitive adhesive layer A copper coating is deposited, and the microprism layer is pressed against the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com