Continuous casting round billet quick-change connecting piece and application thereof

A technology for continuous casting of round billets and connectors, applied in the field of molten steel smelting equipment, can solve problems such as reducing cutting heads, and achieve the effects of reducing cutting heads, improving consistency, and increasing hanging points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

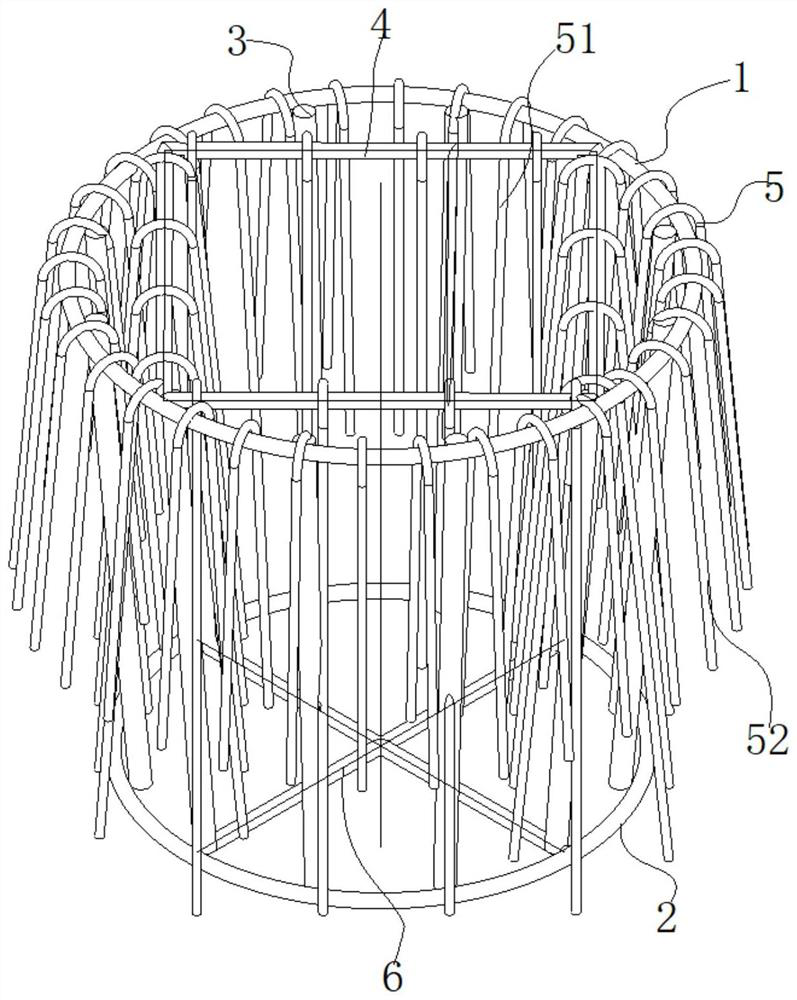

[0031] The continuous casting round billet quick-change coupling in this embodiment includes a tie-bar frame and a hook-shaped tie-bar 5. The tie-bar frame can be a frame structure, and the tie-bar 5 is hooked and fixedly connected to the tie-bar frame; The bar frame and the tie bar 5 are generally made of steel material. The tie bar 5 can be made of steel bars, of course, round steel can also be used. The tie bar frame is generally made of round steel, which has high support strength.

[0032] In the application of the continuous casting round billet quick-change coupling of this embodiment, the continuous casting round billet quick-change coupling body 10 is inserted into the liquid level line 100 of the molten steel in the mold 30 in the gap between the replacement of the tundish 20, which is sufficient Using the initial pre-solidified state of the molten steel in the mold, it has a certain viscosity, which is equivalent to being suspended in the liquid level of the round bi...

Embodiment 2

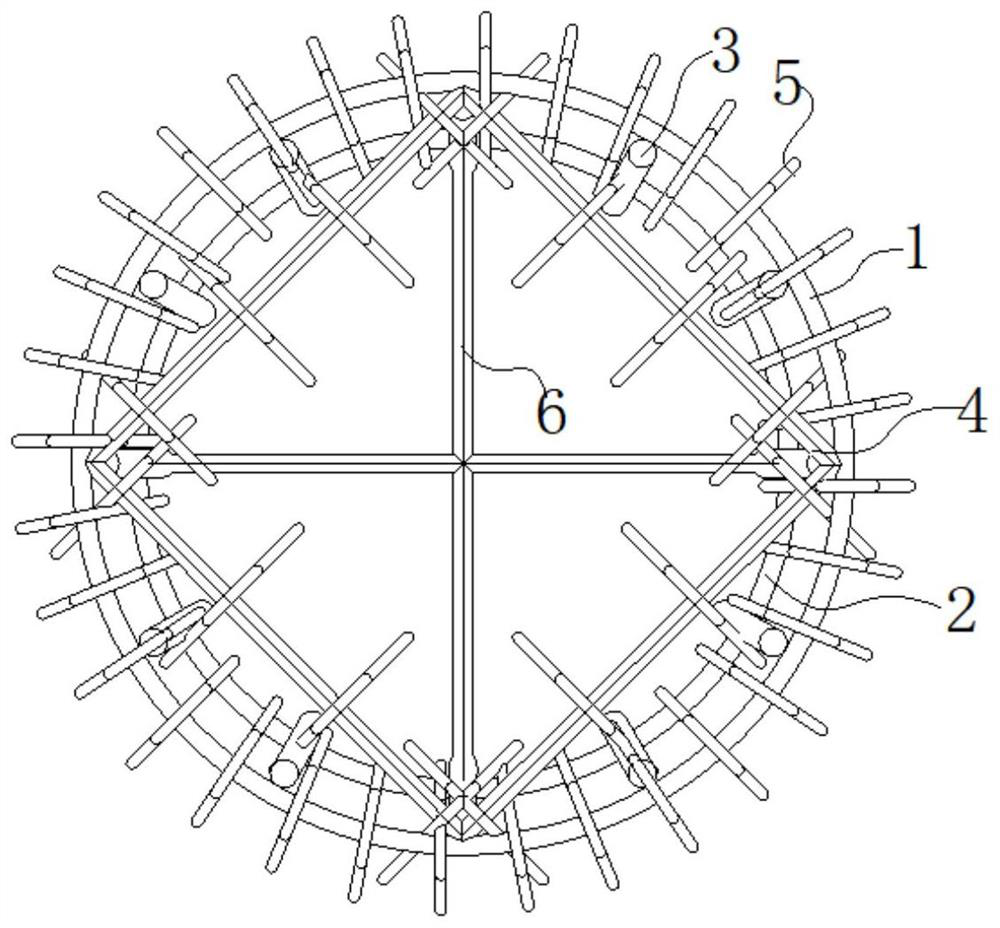

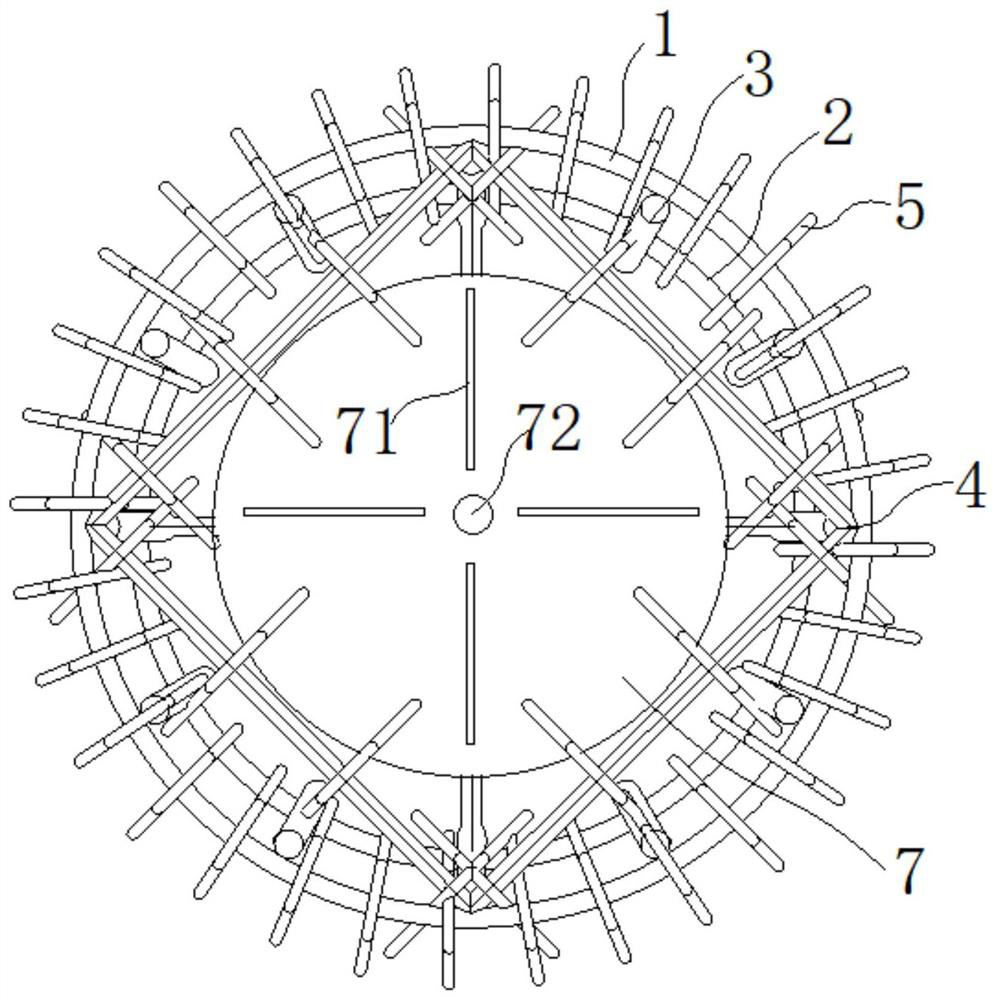

[0034] The basic structure of the continuous casting round billet quick-change coupling of this embodiment is the same as that of Embodiment 1, and the differences and improvements are as follows: figure 1 , 2 As shown, the tie frame is a circular frame that fits the shape of the round blank of the crystallizer 30, and includes a circular upper hanging ring 1 and a lower hanging ring 2 that are fixedly connected by the vertical link 3, which is convenient for the suspension of the tie bar 5. After fixing, The vertical link 3 is generally a round steel with high strength, and is fixed symmetrically or uniformly on the inner side of the upper hanging ring 1 and the lower hanging ring 2, usually by welding; the tie bars 5 evenly or symmetrically surround the upper hanging ring. 1. Hook type fixation, the hanging density can be as large as possible, the spacing distance is about 5 times the diameter of the tie bar 5, which can achieve the purpose of uniform casting with molten ste...

Embodiment 3

[0036] The basic structure of the continuous casting round billet quick-change coupling of this embodiment is the same as that of Embodiment 2, and the differences and improvements are as follows: figure 2 As shown, the inner side of the upper hanging ring 1 is fixedly connected with a square upper hanging frame 4; the upper hanging frame 4 is also hooked and fixedly connected to a hook-shaped tie bar 5 to increase the hanging point of the tie bar 5, and further Improve the overall consistency of the uniform cast slab after the molten steel solidifies. The inner side of the lower hanging ring 2 is connected with a transverse link 6, which can be staggered in an X shape to increase the support strength of the lower hanging ring 2; the tie bar 5 includes an inner hook rod 51 on the inner side of the tie frame frame and an outer hook on the outside Rod 52, the length of the outer hook rod 52 is longer than that of the inner hook rod 51, and is inclined downward and outward, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com