Flat steel production process and production equipment thereof

A technology for production equipment and flat steel, applied in the direction of metal processing equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inability to produce flat steel with tooth shape, lower product yield, and edge material size specifications Instability and other problems, to achieve the effect of strong versatility of raw materials, high equipment utilization rate, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

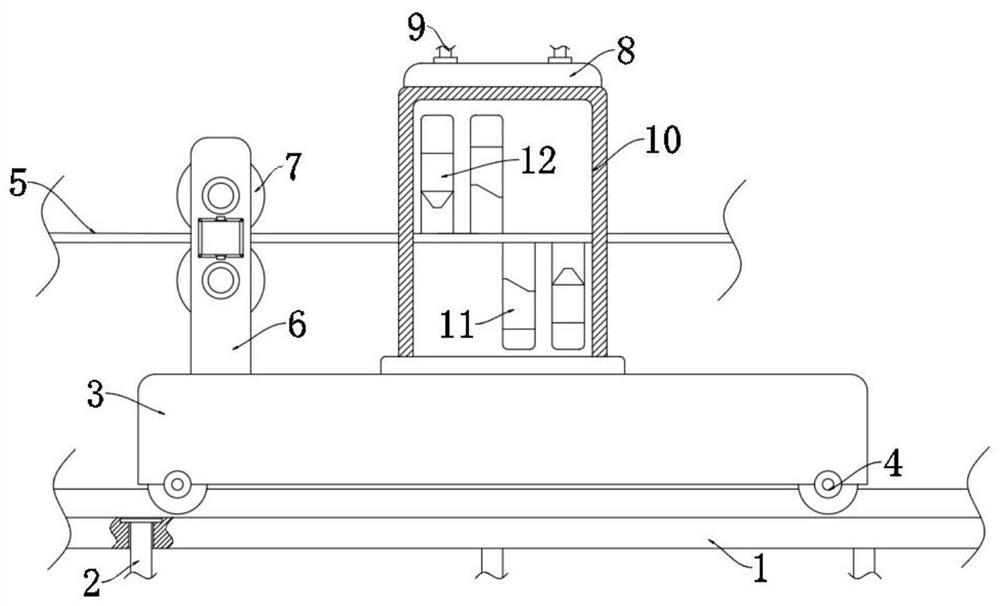

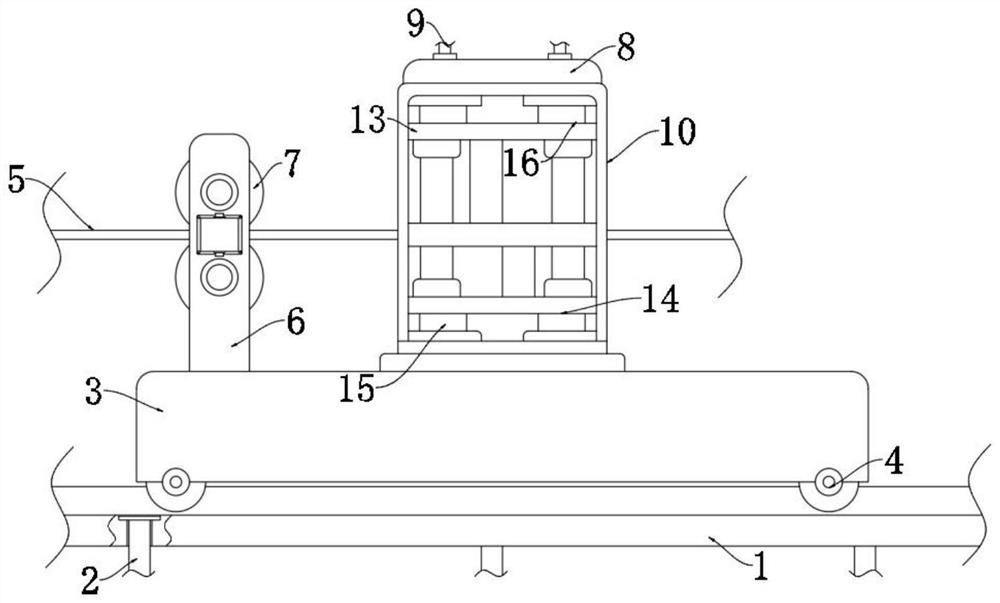

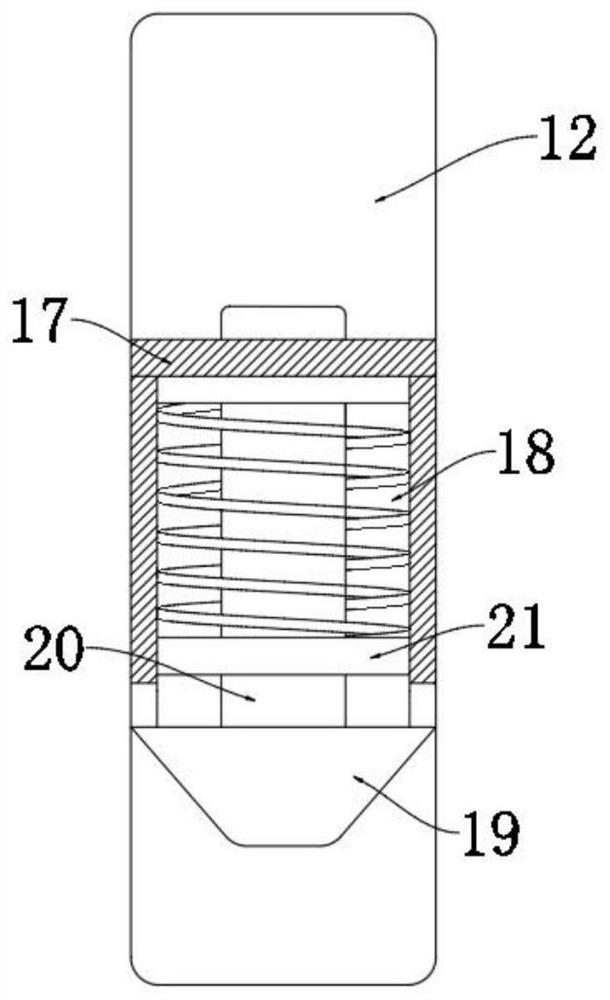

[0030] refer to Figure 1-5 , a wood outer surface grinding device for furniture manufacturing, comprising a running track 1 and a running car 3, a plurality of running wheels 4 are rotatably connected to the running car 3, the running wheels 4 mesh with the running track 1, and a plurality of running wheels are arranged on the running track 1 The countersunk head fixing bolt 2 is fixedly connected with a fixed bracket 6 on the upper end surface of the running car 3, and the fixed bracket 6 is provided with a speed measuring mechanism for realizing the speed measurement in the flat steel transportation process. The semi-finished flat steel 5 is arranged above the running car 3, and the running The upper end surface of the car 3 is fixedly connected with a shearing frame 10, the shearing frame 10 is provided with a shearing mechanism for realizing the shearing of the semi-finished flat steel 5, and the shearing frame 10 is provided with a shearing mechanism for realizing the she...

Embodiment 2

[0045] refer to Figure 4 , the present invention can be implemented through another kind of technological process, specifically comprising:

[0046] S1. Adjust the knives of the slitting unit according to the size of the required finished product, and divide the rolled strip steel into the required narrow strip steel through the slitting and shearing unit;

[0047] S2, sending the cut narrow strip into the cut-to-length shears for cutting;

[0048] S3. Send the cut-to-length finished product to the packaging unit for packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com