Round steel rolling system

A round bar and rolling mill technology, applied in the field of steel rolling, can solve the problems of head bending yield and low dimensional accuracy of rolled pieces, and achieve the effects of reducing head cutting, improving dimensional accuracy and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is designed with the φ75 specification round steel as an example, as follows:

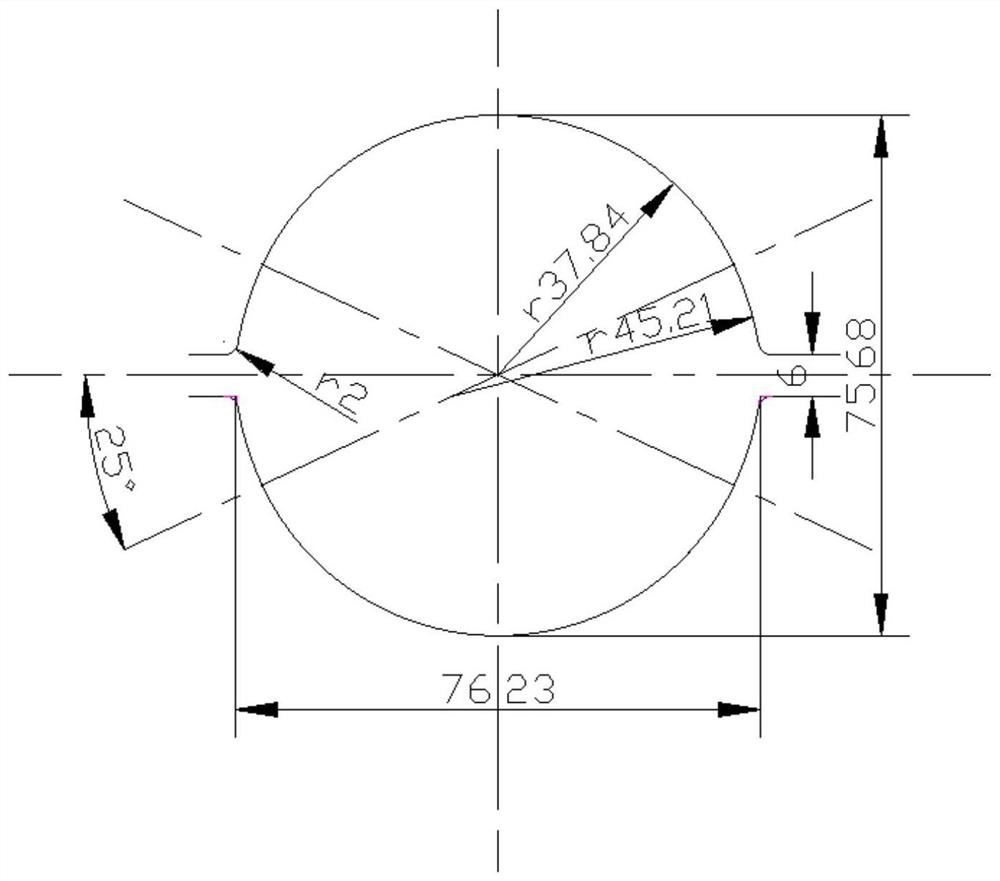

[0053] (1) φ75 finished product and gauge round pass design: such as figure 2 As shown, the design pass height is 75.68mm, width is 76.23mm, roll gap is 6mm, expansion angle is 25°, arc radius is 45.21mm, groove bottom arc radius is 37.84mm, notch arc radius is 2mm .

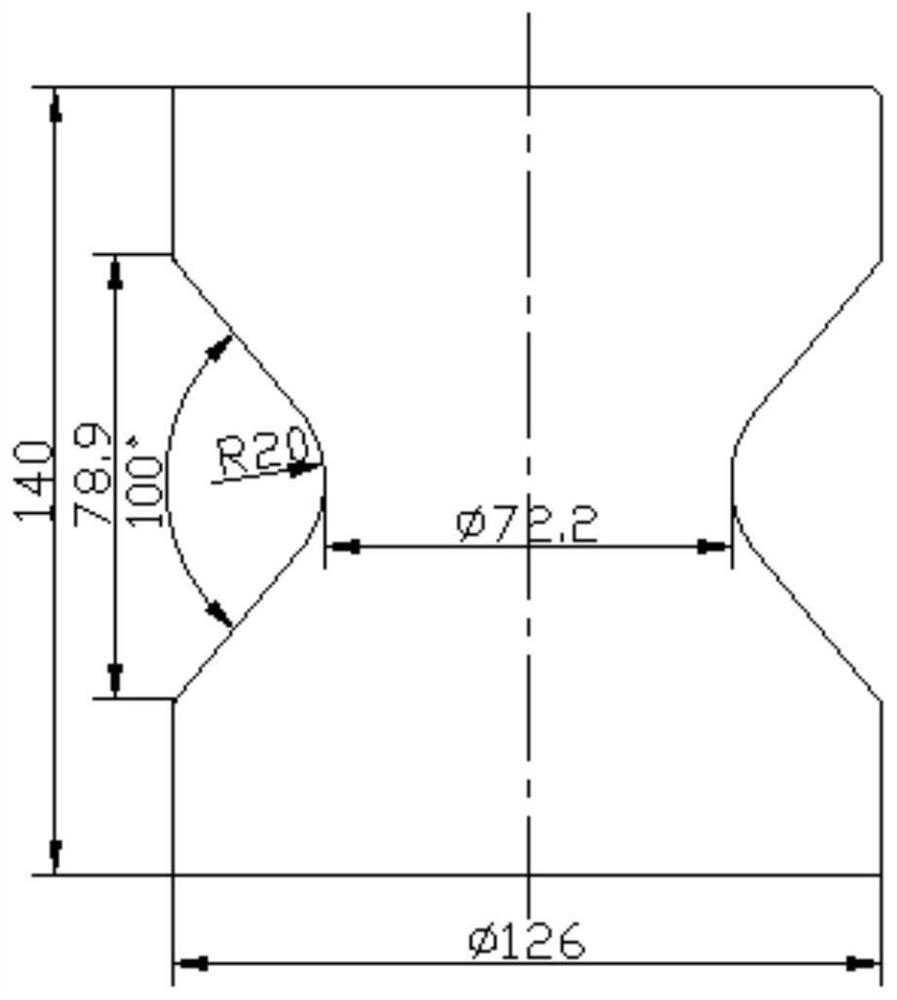

[0054] (2) Guide design: The inlet guide of the round rolling mill adopts the RE140 guide assembly, and the diameter of the inner hole of the pre-guide plate is designed to be φ90mm. Such as image 3 As shown, the guide roller design: the diameter is designed to be φ126mm, and the height is 140mm. Guide roller pass: the opening angle of the pass is 100°, the width is 78.7mm, and the fillet radius at the bottom of the hole is 20mm. The inner diameter of the exit guide is designed to be φ90mm.

[0055] (3) The elongation rate of the circular rolling mill is 1.025, and the effective height of the rolled piece ...

Embodiment 2

[0058] This embodiment is designed with the φ55 specification round steel as an example, as follows:

[0059] (1) φ55 finished product and gauge round pass design: such as Figure 4 As shown, the design pass height is 55.80mm, the width is 56.50mm, the roll gap is 5mm, the expansion angle is 25°, the arc radius is 37.60mm, the groove bottom arc radius is 27.90mm, and the notch arc radius is 2mm .

[0060] (2) Guide design: The inlet guide of the round rolling mill adopts the RE110 guide assembly, and the diameter of the inner hole of the pre-guide plate is designed to be φ70mm. Such as Figure 5 As shown, the guide roller design: the diameter is designed to be φ113mm, and the height is 127mm. Guide roller pass: the opening angle of the pass is 100°, the width is 74mm, and the fillet radius at the bottom of the hole is 20mm. The inner diameter of the exit guide is designed to be φ68mm.

[0061] (3) The elongation rate of the circular rolling mill is 1.028, and the effectiv...

Embodiment 3

[0064] This embodiment is designed with the φ130 specification round steel as an example, as follows:

[0065] (1) φ130 finished product and gauge round pass design: such as Image 6 As shown, the design pass height is 131.88mm, width is 133.09mm, roll gap is 8mm, expansion angle is 20°, arc radius is 89.29mm, groove bottom arc radius is 65.94mm, notch arc radius is 4mm .

[0066] (2) Guide design: The inlet guide of the round rolling mill adopts the RE180 guide assembly, and the diameter of the inner hole of the pre-guide plate is designed to be φ152mm. Such as Figure 7 As shown, the design of the guide roller: the diameter is designed to be φ200mm, and the height is 186mm. Guide roller pass: the opening angle of the pass is 100°, the width is 148.6mm, and the fillet radius at the bottom of the hole is 60mm. The inner diameter of the exit guide is designed to be φ150mm.

[0067] (3) The elongation rate of the circular rolling mill is 1.024, and the effective height of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com