Novel straw compression forming equipment

A technology of compression molding and straw, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of frequent shutdown, small output, high labor intensity, etc., and achieve increased frictional shear force, reasonable ratio matching, Ease of replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

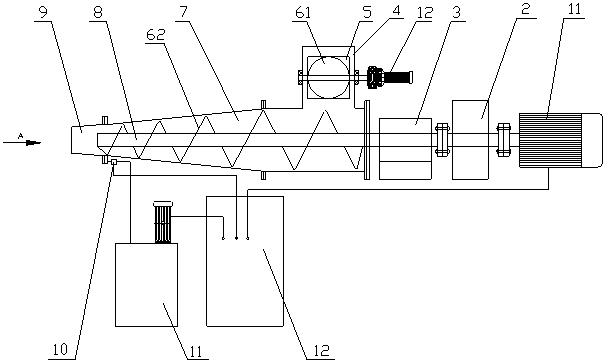

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

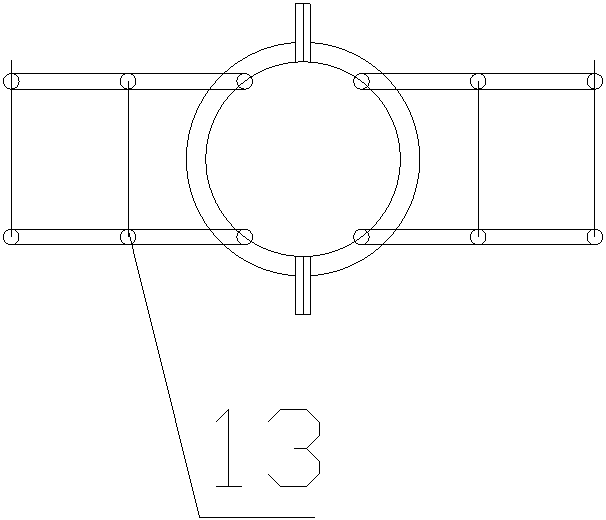

[0021] The present invention is a new type of straw compression molding equipment, including a main drive mechanism, a pre-compression mechanism and a compression mechanism, the main drive mechanism includes a first motor 1, a reducer 2 and a bearing sleeve 3, the first motor 11, a reducer 2 and the bearing sleeve 3 are sequentially connected through the compression main shaft 8, and the pre-compression mechanism includes the second motor 12, the feed box 4, the pre-compression auger 61 and the forced feeding flap 5, and the forced feeding flap 5 is set Below the pre-compression auger 61, the compression mechanism includes the compression main shaft 8 and the compression auger 62 centered on the compression main shaft 8, the outlet end of the compression chamber 7 is provided with a reinforced compression chamber 9, and the reinforced The side wall of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com