Cast aluminum inorganic used sand regeneration and reusing combined method

It is an old sand regeneration and inorganic technology, which is applied in the cleaning/processing machinery, casting molds, casting molding equipment, etc. of casting materials to achieve the effects of prolonging the service life, uniform heating, and avoiding poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

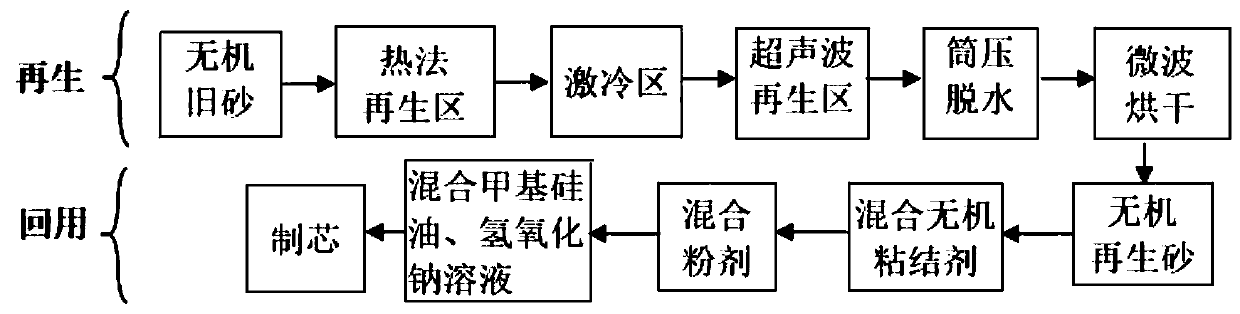

[0042] A. Inorganic old sand regeneration

[0043] The old inorganic sand is crushed by the drum to below 20 meshes, and sent to the old inorganic sand silo; the old inorganic sand is transported from the silo to the horizontal roasting furnace through the bucket elevator for roasting; the roasting temperature is set at 500°C, and the roasting time is 3 hours; The roasted sand is cooled by an inclined cooling tank, the cooling tank is inclined downward along the flow direction of the sand, and the inclination angle is 5°. There is a circulating water pipe at the bottom of the cooling tank to cool the sand to 100-200 °C; The cooling tank enters the rain-type lower sand port, and then falls vertically into the trough-type ultrasonic water tank for wet regeneration. The ultrasonic water tank is 2m in height, 1m in length, and 1m in width. , the height of the solution in the ultrasonic water tank is no more than 4 / 5 of the height of the water tank, including 98% of water, 1.3% of ...

Embodiment 2

[0047] A. Inorganic old sand regeneration

[0048] The old inorganic sand is crushed by a drum to below 20 mesh, and sent to the old inorganic sand silo; the old inorganic sand is transported from the silo to the horizontal roasting furnace through the bucket elevator for roasting; the roasting temperature is set at 800°C, and the roasting time is 5 hours; The roasted sand is cooled by an inclined cooling tank, the cooling tank is inclined downward along the flow direction of the sand, and the inclination angle is 10°. There is a circulating water pipe at the bottom of the cooling tank to cool the sand to 100-200 ° C; the sand enters the rain from the cooling tank The sand mouth is lowered in a vertical manner, and then vertically falls into the trough-type ultrasonic water tank for wet regeneration. The ultrasonic water tank has a height of 5m, a length of 0.5m, and a width of 0.5m. The ultrasonic waves are placed on the side of the water tank. The height of the solution in t...

Embodiment 3

[0052] A. Inorganic old sand regeneration

[0053] The old inorganic sand is crushed by the drum to below 20 mesh, and sent to the old inorganic sand silo; the old inorganic sand is transported from the silo to the horizontal roasting furnace through the bucket elevator for roasting; the roasting temperature is set at 300°C, and the roasting time is 0.5h The roasted sand is cooled by an inclined cooling tank, the cooling tank is inclined downward along the flow direction of the sand, the inclination angle is 2°, and a circulating water pipe is installed at the bottom of the cooling tank to cool the sand to 100-200°C; the sand enters the rain from the cooling tank The shower-type lower sand mouth, and then vertically fall into the trough-type ultrasonic water tank for wet regeneration. The ultrasonic water tank has a height of 1m, a length of 2m, and a width of 2m. The ultrasonic waves are placed on the side of the water tank. The height of the solution in the water tank does n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com