Power assembly for electric passenger car

A powertrain and electric car technology, applied to vehicle components, transmission parts, control devices, etc., can solve problems such as low machining accuracy, severe vibration, and incoordination, so as to improve machining accuracy and assembly accuracy, and move flexibly and reliably , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

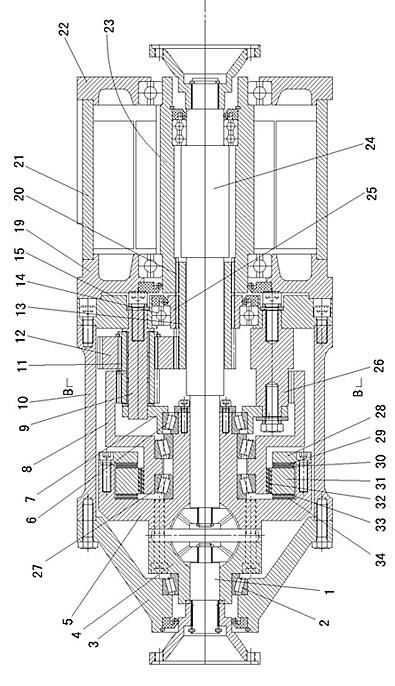

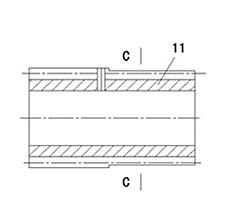

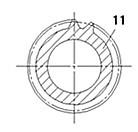

[0026] Such as Figure 1-7 As shown: the reducer housing is composed of a reducer casing 10 , a reducer left cover 3 and a reducer right cover 15 which are bolted to the reducer casing 10 . A differential housing is arranged in the reducer housing, and the differential housing is composed of a differential left housing 4 and a differential right housing 5 fixedly connected by bolts. Differential parts are arranged in the differential case, and the left half shaft 1 and the right half shaft 24 connected with the differential parts protrude to the left and right respectively.

[0027] The right side of the speed reducer housing is fixedly connected with the drive motor housing, and the drive motor housing is made up of the middle housing 21, the motor left cover 19 and the motor right cover 22 fixedly connected with the middle housing 21 bolts. The motor left cover 19 is fixedly connected with the reducer right cover 15 by bolts.

[0028] The first bearing 2 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com