Glue spraying device preventing slide block from disengaging from slide rod

A technology of glue spraying and sliding bar, which is applied in the direction of shoemaking machinery, clothing, and bonding shoe parts, etc. It can solve the problems that the slider is easy to slide out of the slide bar, and the position of the glue spraying gun cannot be adjusted back and forth, so as to achieve smooth sliding and structural stability. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

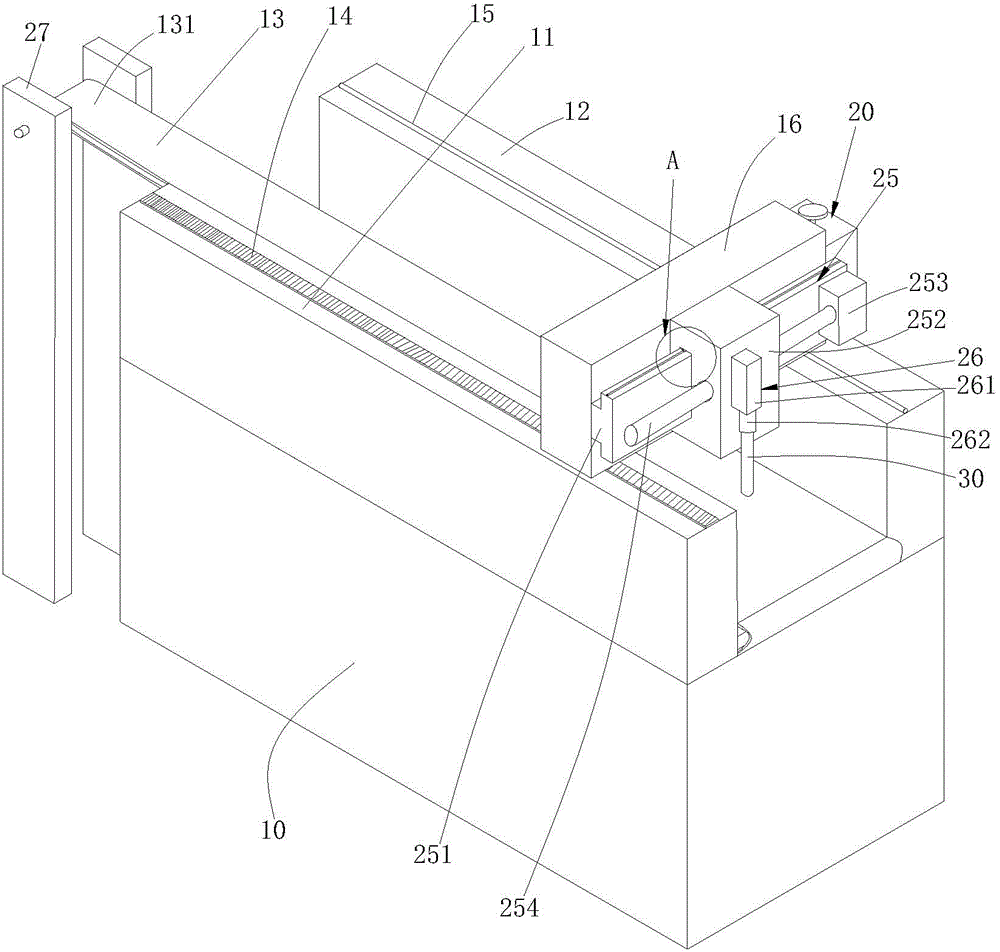

[0019] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

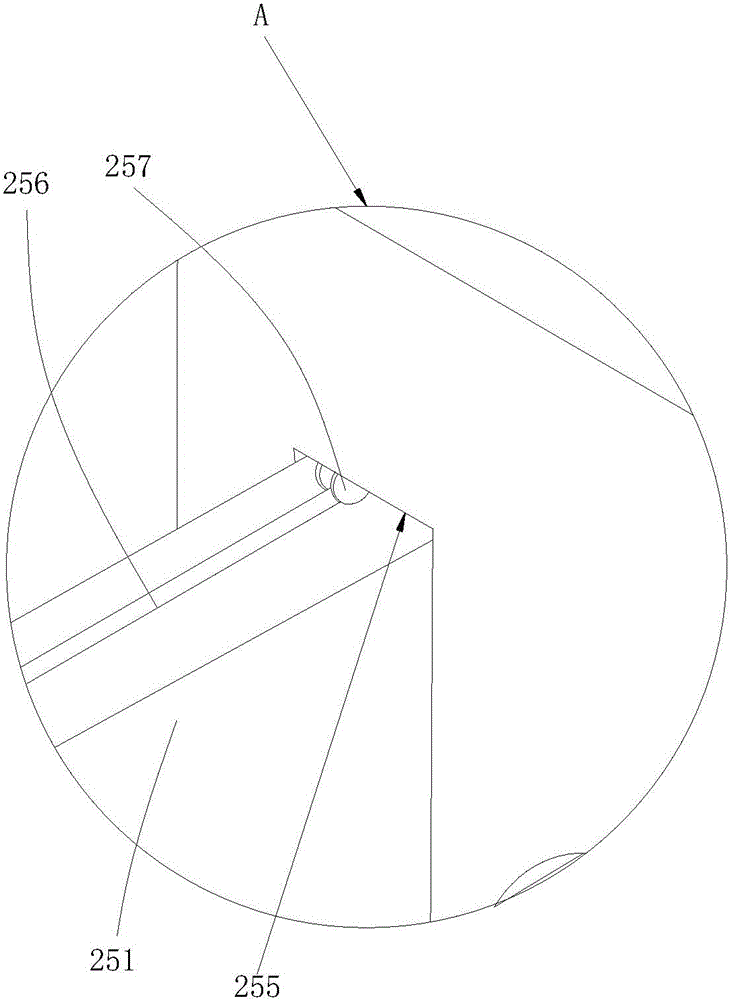

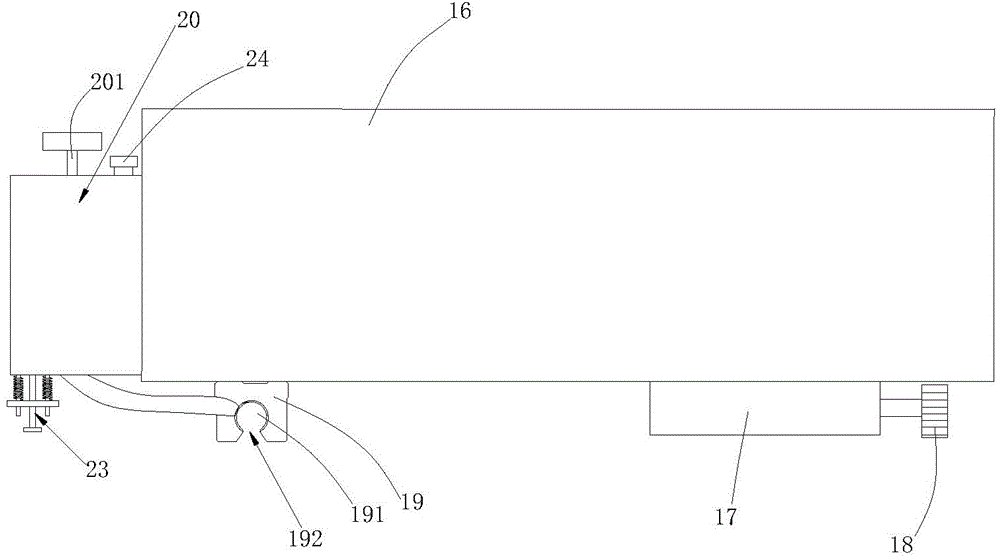

[0020] refer to figure 1 and image 3 , a glue spraying device that prevents the slider from detaching from the slide bar, the glue spraying device includes a mounting table 10 and a controller (not shown) for controlling the operation of the glue spraying device. The left and right sides of the top of the mounting table 10 are respectively provided with a left convex edge 11 and a right convex edge 12 . A conveyor belt 13 for conveying shoe soles is installed between the left convex edge 11 and the right convex edge 12 . A toothed belt 14 is provided on the left convex edge 11, and a tooth pattern is provided on the toothed belt 14, and a slide bar 15 is provided on the right convex edge 12. Glue spraying device also comprises the first installation block 16 that is used to install glue spray gun 30, the left side of the first installation block 16 bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com