Water spraying device of electrolytic copper foil device

A technology of electrolytic copper foil and spray device, which is applied in the direction of electrolysis process, electroforming, cleaning method and utensils, etc., to achieve the effect of reducing counterweight design, improving surface quality and reducing frictional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

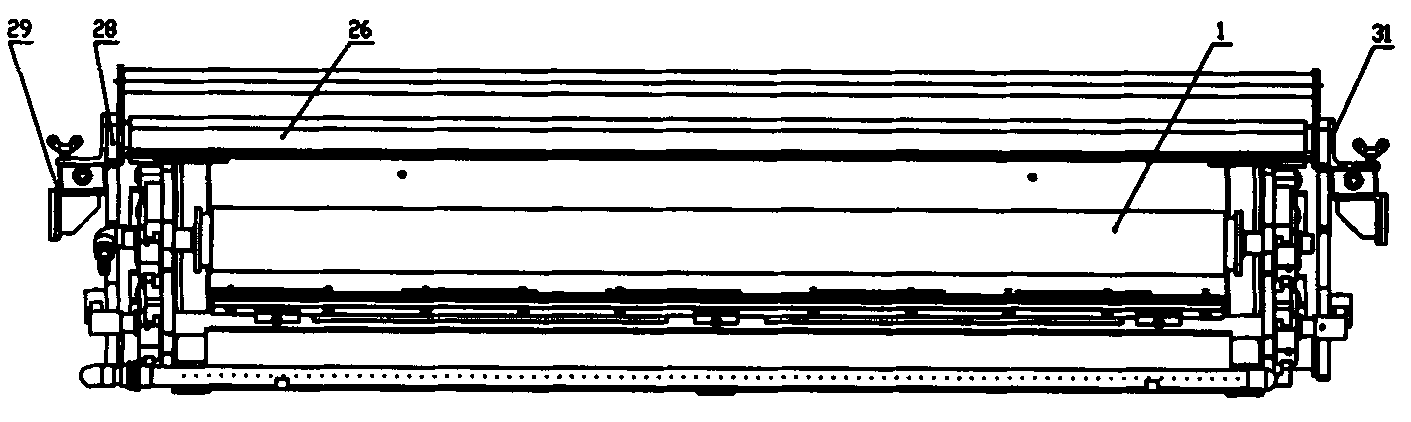

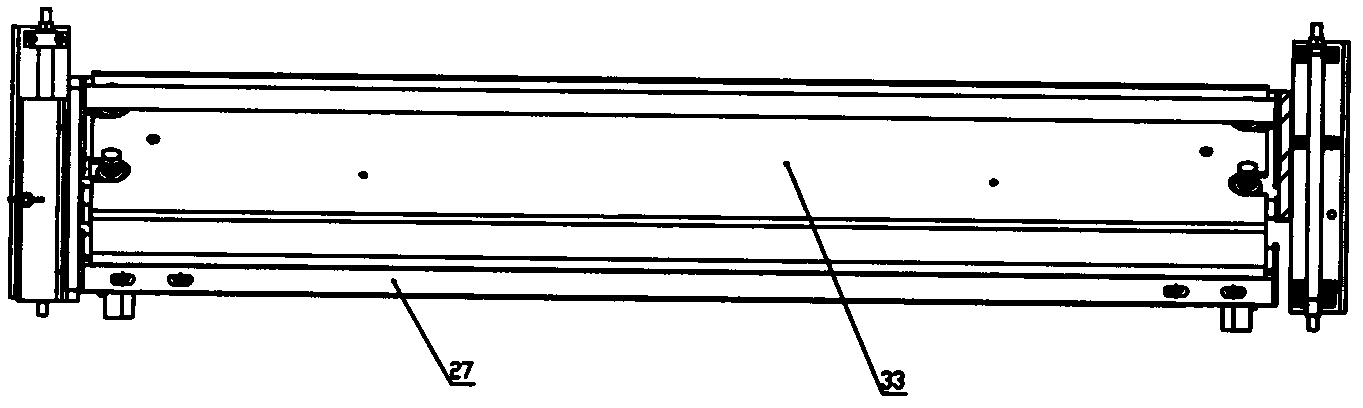

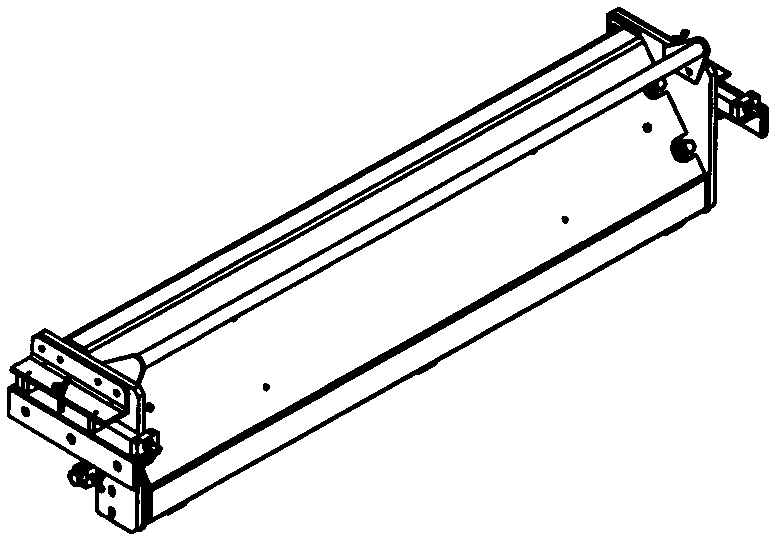

[0022] The water washing and spraying device for electrolytic copper foil equipment includes a squeeze roller bracket set on the fixed plate, a squeeze roller set on the squeeze roller bracket, a slide rail horizontally set on the fixed plate and a squeeze roller bracket The sliding sleeve is a stainless steel rubber-coated roller set between the fixed plates and located on the upper surface of the copper foil.

[0023] The water squeezing roller of the present invention is fixed by a slide rail, and the sliding sleeve is made of F4 plastic to make the sliding smoother. When it is necessary to move the water squeezing roller, it is only necessary to slide the entire water squeezing device outward along the slide rail to a sufficient position, and then pass the Simple positioning of the screw. Through this improvement, it is not necessary to lift the squeeze roller directly when assembling and disassembling the cathode roller, thus saving the leveling work of the squeeze roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com