Novel hub power device and electric bicycle

A power unit and wheel hub technology, which is applied to wheel transmissions, electromechanical devices, electric components, etc., can solve the problems of small output torque, large volume, and difficult climbing, and achieve large transmission ratio, small structural volume, and safety factor. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

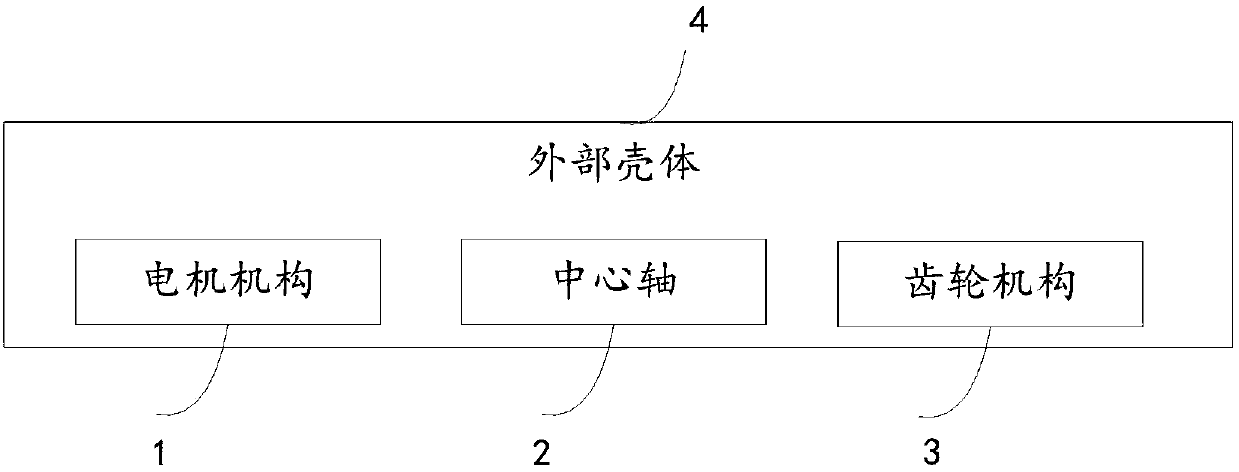

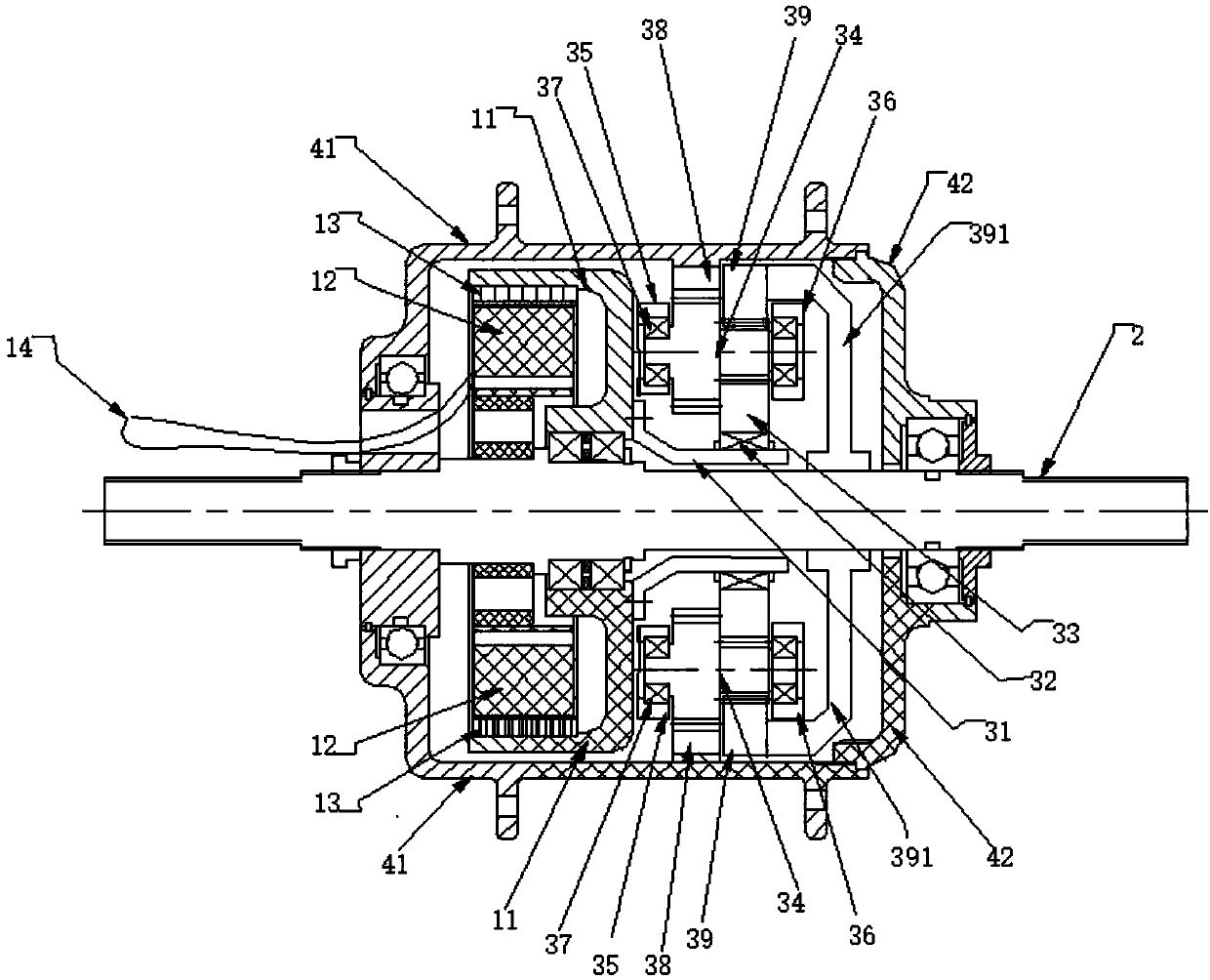

[0037] This embodiment proposes a novel hub power device, such as figure 1 As shown, the device includes a motor mechanism 1, a central shaft 2, a gear mechanism 3 and an external housing 4; specifically, as figure 2 As shown, the motor mechanism 1, the central shaft 2, and the gear mechanism 3 are all located in the outer casing 4, and the central shaft 2 is a fixed shaft, and the motor mechanism 1 and the gear mechanism 3 are sleeved on the outer casing 4. on the central axis 2;

[0038] Such as figure 2As shown, the gear mechanism 3 includes a hollow shaft sleeve 31, a one-way clutch 32, a sun gear 33, and a double planetary gear 34 that are arranged outwardly on the central shaft 2 in sequence; and one end of the hollow shaft sleeve 31 It is fixedly connected with the motor mechanism 1, and the other end of the hollow shaft sleeve 31 is in interference fit with the inner ring of the one-way clutch 32; the outer ring of the one-way clutch 32 is in contact with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com