Foamed brick cutting device for reducing rejection rate

A cutting device and technology for foaming bricks, applied to ceramic molding machines, manufacturing tools, etc., can solve problems such as high scrap rate and non-conformity to specifications, and achieve the effect of reducing power requirements, reducing scrap rate, and reducing product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

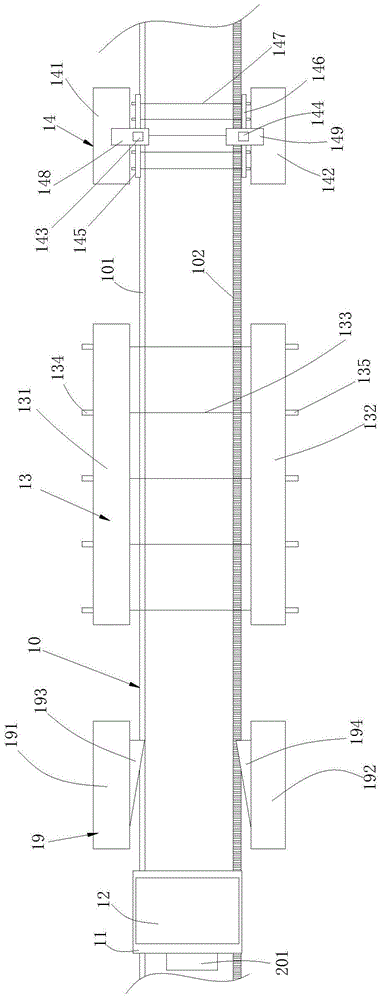

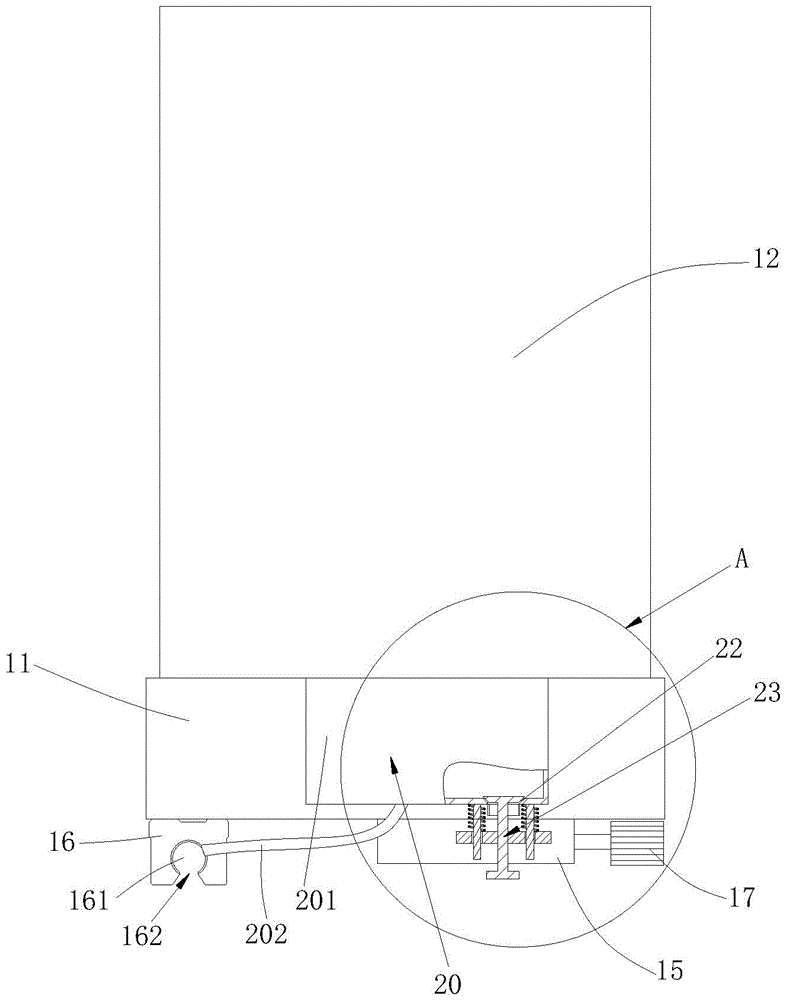

[0023] refer to figure 1 , a foam brick cutting device that reduces the reject rate, comprising a rail 10, a pallet 11 slidably mounted on the rail 10, a foam brick 12 placed on the pallet 11, and a foam brick 12 for A horizontal cutting device 13 for cutting the foam brick 12 into small blocks along the horizontal direction, and a vertical cutting device 14 for cutting the foamed brick 12 into small blocks along the vertical direction.

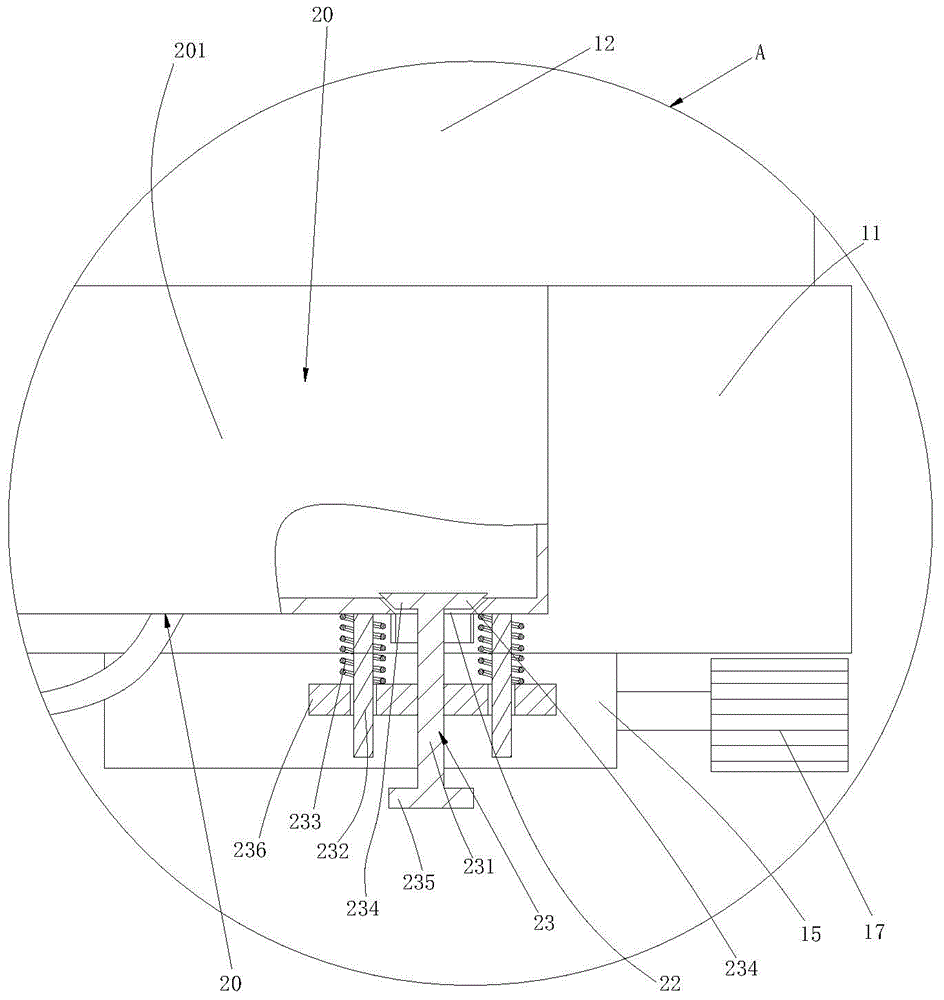

[0024] Such as figure 1 and figure 2 As shown, the track 10 includes a slide bar 101 and a toothed belt 102 , the toothed belt 102 is provided with tooth lines, and the bottom of the pallet 11 is provided with a servo motor 15 and a slider 16 that can slide on the slide bar 101 . The output shaft of the servo motor 15 is equipped with a gear 17 that can walk on the toothed belt 102 . The horizontal cutting device 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com