Floating type shaver

A razor, floating technology, applied in the field of floating shavers, can solve the problems of not being able to meet the needs of high-comfort use, and the floating angle of the cutter head is limited, so as to speed up the curing reaction process, easy to rotate, and increase the rotation The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

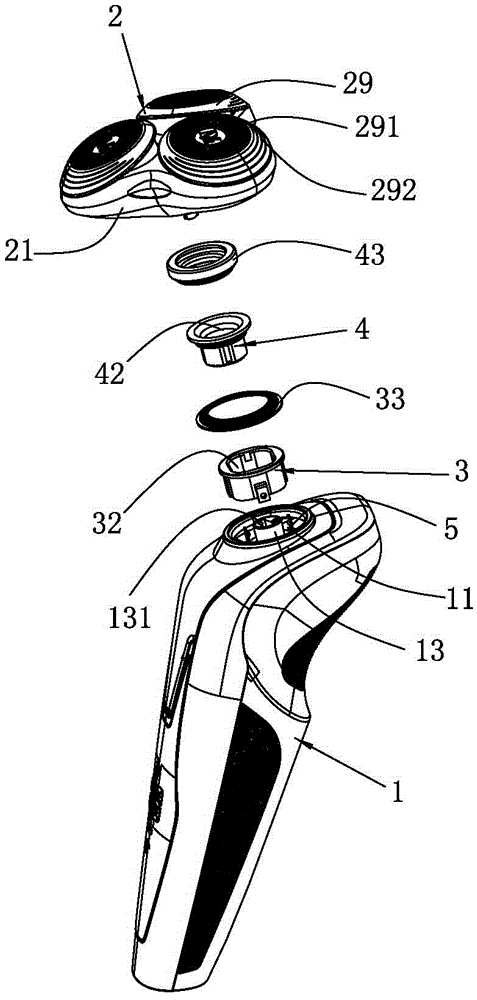

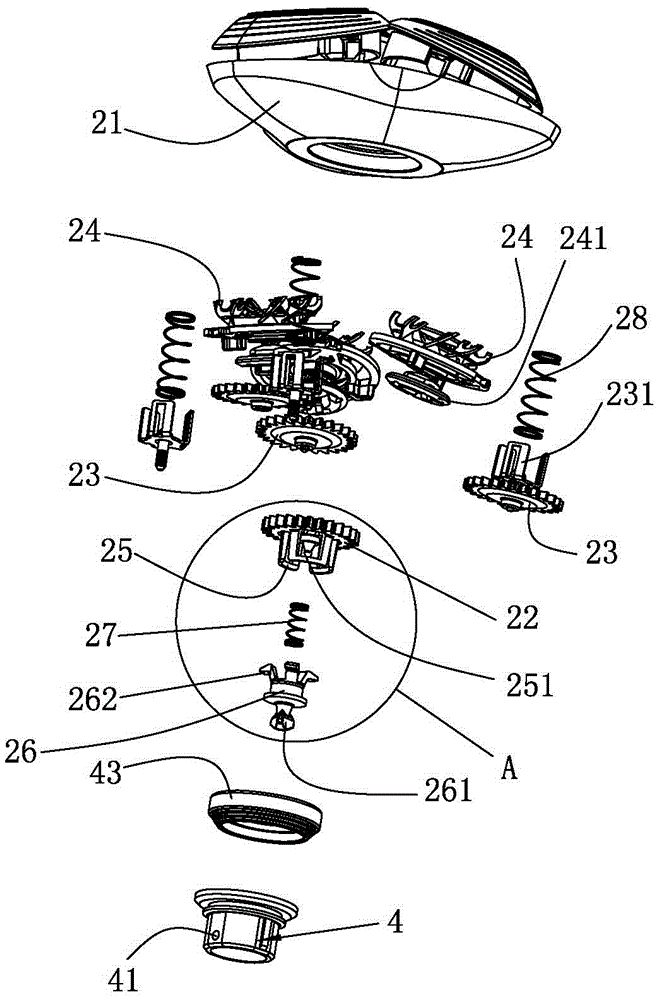

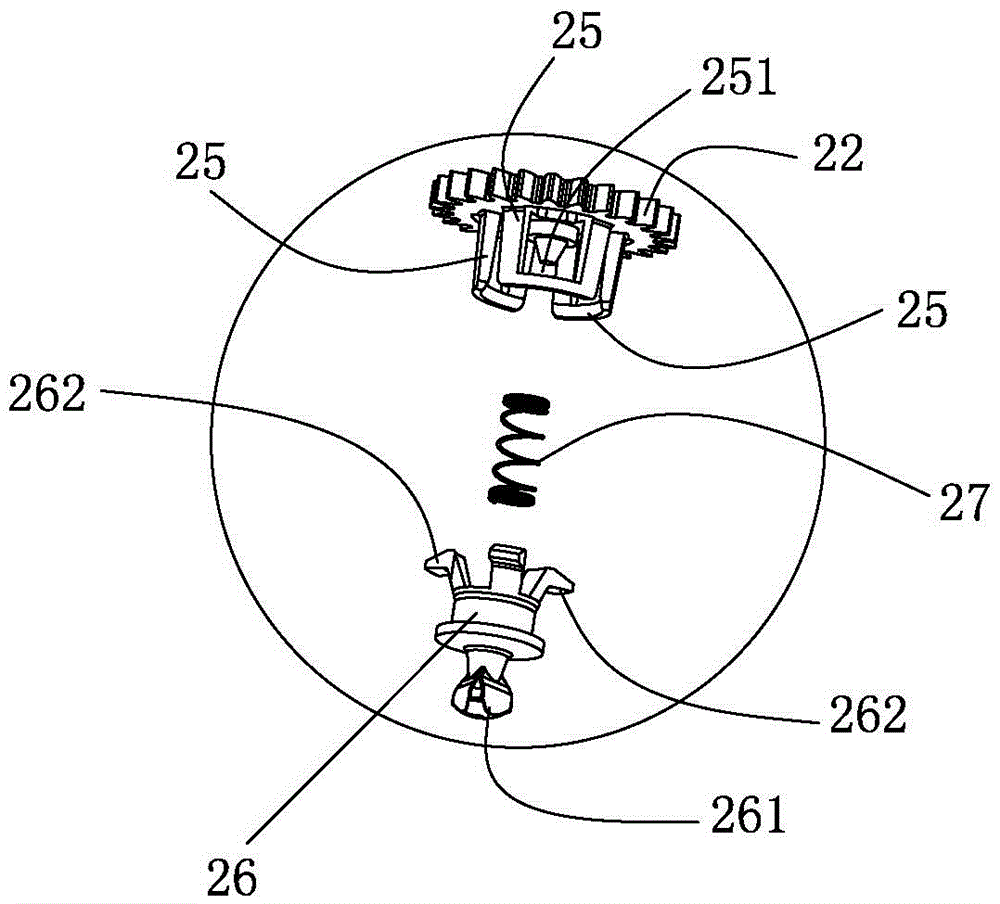

[0068] see Figure 1 to Figure 4 , a floating shaver of the present invention comprises a head 2, a casing 21 mounted on the outer layer of the head 2, a main shell 1 for holding, and a first through hole 32. The floating part 3 and the second floating part 4 arranged in the first through hole 32, the second floating part 4 is provided with a second through hole 42, and the main shell 1 is also recessed for accommodating the first floating part 3 The accommodating groove 11, the left and right sides of the first floating member 3 are respectively provided with a first female pivot joint 31, and the accommodating groove 11 is provided with a pair of first sub-joints matching the first female pivot joint 31. The pivot joint 12, the bottom of the first floating member 3 is fixedly provided with a clamping piece 5, and the clamping piece 5 is provided with clamping pieces 51 protruding into the front and rear sides of the first through hole 32. The holding piece 51 is provided wi...

Embodiment 2

[0085] The difference between this embodiment and Embodiment 1 is that: the first elastic sleeve 33 and the second elastic sleeve 43 are both elastic silicone rubber sleeves.

[0086] Wherein, the elastic silicone rubber sleeve is composed of the following raw materials:

[0087] A component

[0088] Polysiloxane (Ⅰ) 55 parts

[0089] 5.5 parts of cross-linking agent

[0090] Filling 35 parts

[0091] 5.5 parts of coupling agent

[0092] Polysiloxane (Ⅱ) 20 parts

[0093] B component

[0094] Polysiloxane (Ⅲ) 65 parts

[0095] Catalyst 0.2 part

[0096] Inhibitor 9 parts

[0097] 9 parts acrylate compound

[0098] The structural formula of the linear polysiloxane (I) is:

[0099]

[0100] The chain number of the polysiloxane (I) is α=4500, β=250,

[0101] The structural formulas of the polysiloxanes (II) and (III) are both:

[0102]

[0103] The number of chain members of the polysiloxane (II) γ=6000, δ=300;

[0104] The number of chain members of the polysi...

Embodiment 3

[0114] The difference between this embodiment and Embodiment 1 is that: the first elastic sleeve 33 and the second elastic sleeve 43 are both elastic silicone rubber sleeves.

[0115] Wherein, the elastic silicone rubber sleeve is composed of the following raw materials:

[0116] A component

[0117] Polysiloxane (Ⅰ) 60 parts

[0118] Cross-linking agent 10 parts

[0119] Filling material 40 parts

[0120] 10 parts of coupling agent

[0121] Polysiloxane (Ⅱ) 30 parts

[0122] B component

[0123] Polysiloxane (Ⅲ) 70 parts

[0124] Catalyst 0.3 part

[0125] Inhibitor 8 parts

[0126] Acrylate compound 8 parts

[0127] The structural formula of the linear polysiloxane (I) is:

[0128]

[0129] The chain number of polysiloxane (I) is α=3000, β=200,

[0130] The structural formulas of the polysiloxanes (II) and (III) are both:

[0131]

[0132] The number of chain members of the polysiloxane (II) γ=5000, δ=200;

[0133] The number of chain members of the polysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com