Tyre laser speckle inspection machine and inspection method thereof

A technology of laser speckle and inspection method, which is applied in the field of rubber machinery, can solve problems such as prone to swing and deflection, increase of instability factors of the detection head, and distortion of scanning images, so as to improve the ability of rotation angle and precise positioning , shorten the inspection cycle, and the effect of scanning images without distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

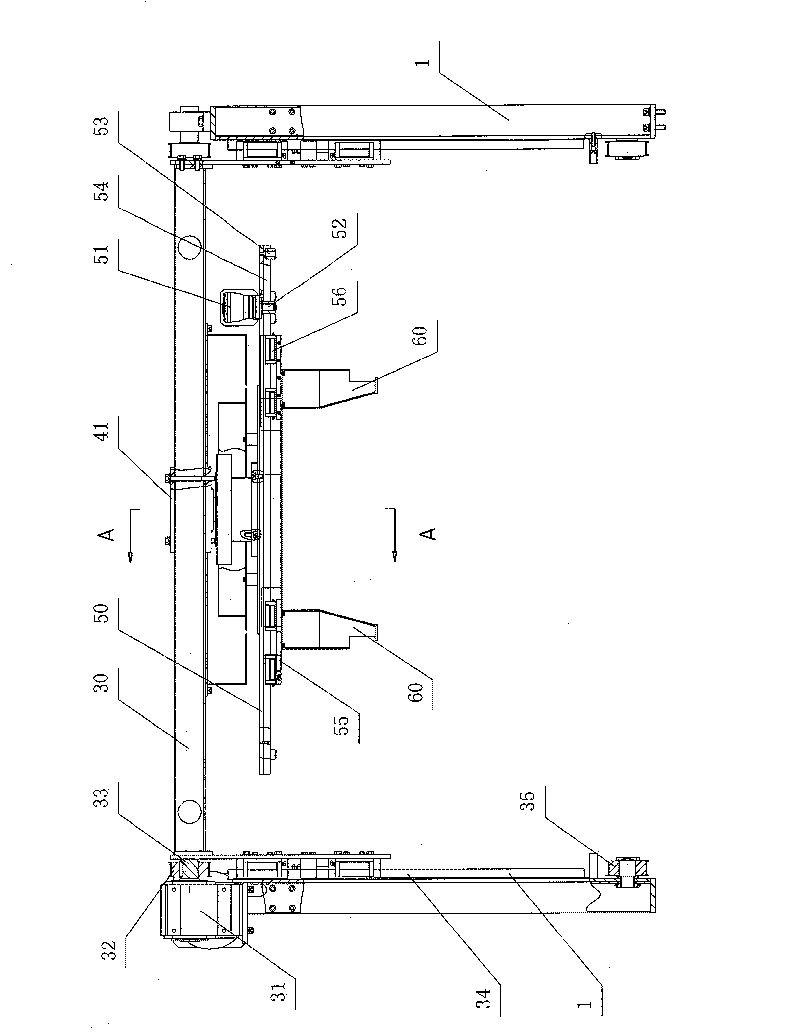

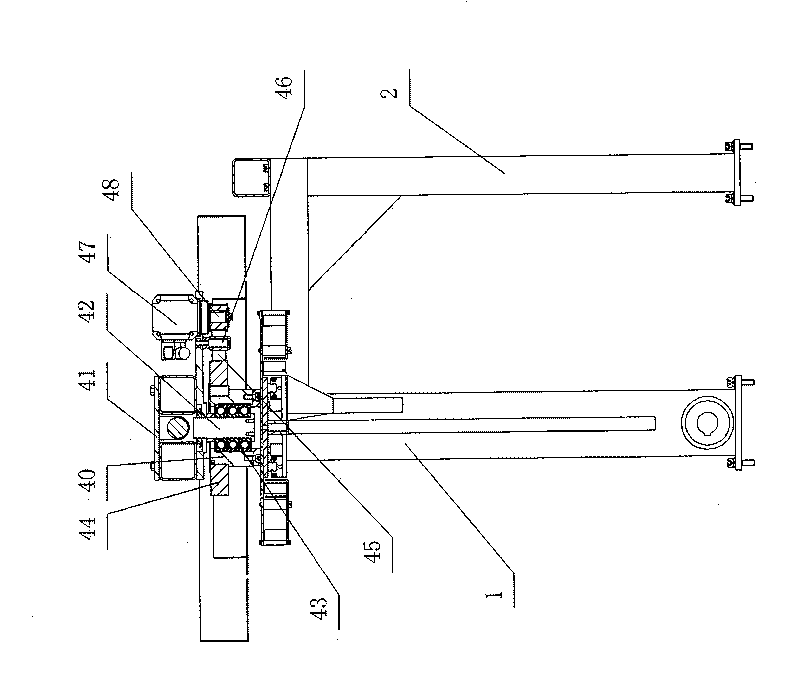

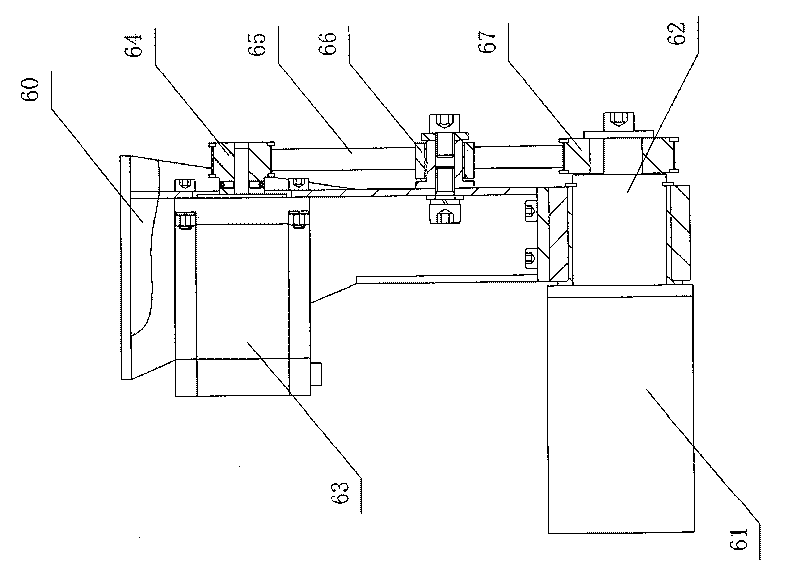

[0040] Example 1, such as Figure 1 to Figure 4 As shown, the tire laser speckle inspection machine mainly has a frame 1, a support frame 2, a lifting device, a rotating device, a horizontal reciprocating device and a laser detection device. in,

[0041] The support frame 2 is connected to one side of the frame 1, and the support frame 2 supports the frame 1 from one side, which is beneficial to improve the reinforcement and stability of the laser detection device during rotation, so as to avoid the shaking of the laser detection head.

[0042] The lifting device is arranged in 2 groups, which are installed on the frame 1 respectively, and the rotating device is installed on the lifting beam 30 of the lifting device.

[0043] Each group of lifting devices also includes a lifting motor 31, a driving pulley 32, a lifting shaft 33, a lifting synchronous belt 34, and a driven pulley 35.

[0044] The lifting motor 31 is connected with the lifting shaft 33, the lifting shaft 33 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com