350MW supercritical boiler combustor nozzle tube panel device and method

A burner nozzle and supercritical boiler technology, applied in the field of boilers, can solve the problems of low operating efficiency and low steam parameters of power plants, and achieve the effects of simple installation, light weight, and overcoming the shortcomings of hedging combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

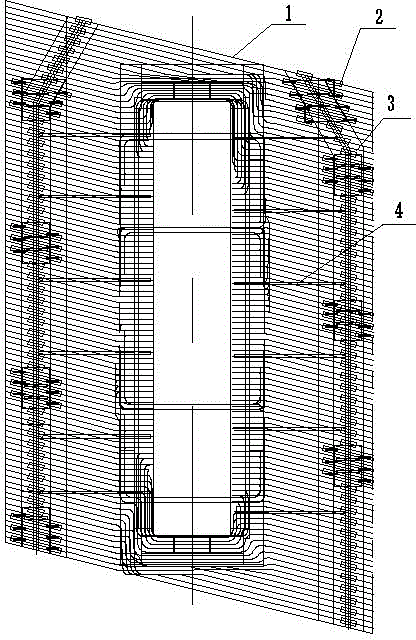

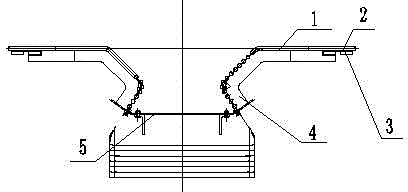

[0020] 350MW supercritical boiler burner nozzle tube panel device, its composition includes: the tube panel connected to the pipe 1, the tube panel is bent in sections according to the smallest possible radius of curvature, and the tube is passed through the burner bellows, the tube panel The protruding part of the load is connected to the burner and the water wall of the boiler by connecting pieces, and the burner and the water wall are connected to the frame beam through the tension plate 3 .

Embodiment 2

[0022] In the 350MW supercritical boiler burner nozzle tube panel device described in Example 1, the tube is a spiral coil structure, the tube is installed at an angle of 13.94 degrees to the horizontal line, and the tubes 1 are evenly distributed. A group of pipes 1 described above is connected with a group of spacers 2, and the spacers 2 are connected with comb plates 4, and flange plates 5 with angles are installed between the pipes 1.

Embodiment 3

[0024] 350MW Supercritical Boiler Burner Nozzle Tube Screen Fixing Treatment Method, adopting the method of sub-sections to bend the tube according to the minimum curvature that can be realized on site, passing the tube in the burner air box; controlling the vertical upward or downward direction of the bent tube through the tube screen The height of the water cycle is guaranteed to ensure the safety and reliability of the water cycle; the protruding part of the tube panel load and the set-up part of the burner are connected to the water wall by connecting pieces, and then transmitted to the frame beam of the boiler through the tension plate, because most of the pipes have to pass through the burner air box , After the tube panel is produced first during assembly, the split burner is assembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com