Main steel frame node device of tower type supercritical boiler and connecting method

A supercritical boiler and main steel frame technology, applied in boiler support/positioning devices, lighting and heating equipment, fluid heaters, etc., can solve problems such as being unable to withstand such a heavy weight, large force on a single rod, and large length , to achieve the effect of clear and reliable transmission power, reliable connection and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

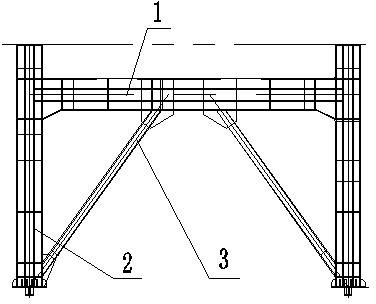

[0020] A main steel frame node device of a tower-type supercritical boiler, comprising: a beam 1, two ends of the beam 1 are respectively connected to a group of columns 2, and the lower end of the beam 1 is connected to the lower part of a group of columns through a vertical support 3 .

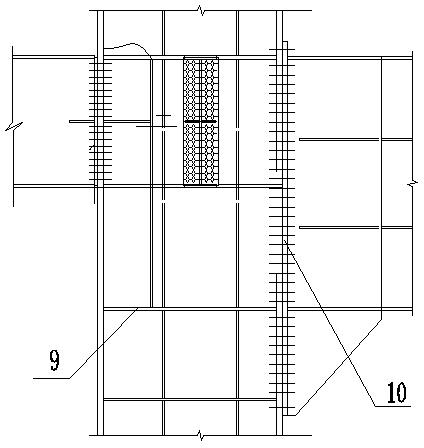

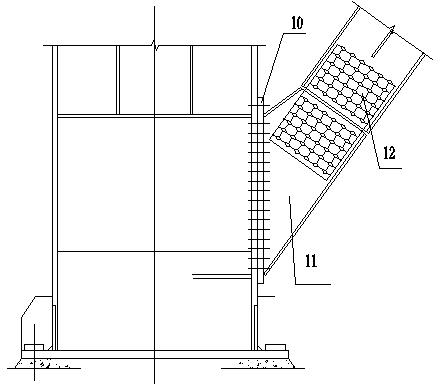

[0021] The group of columns 2 includes a lower column 4, the lower column 4 is connected to the lower column end plate 5, the lower column end plate 5 is connected to the upper column end plate 7 through bolts 6, and the upper column end plate is 7. Connect the upper column 8, the lower column and the upper column are connected to the annular stiffener 9, the lower column and the upper column are connected to the end plate 10, and the end plate 10 is connected by bolts The box-shaped transition connecting piece 11 is connected to the connecting plate 12 . In order to increase the rigidity of the structure, the connection between the beam and the column of the tower boiler is rigid, while th...

Embodiment 2

[0023] In the main steel frame node device of the tower-type supercritical boiler described in Embodiment 1, the box-shaped transition connecting piece and the connecting piece form the vertical support.

Embodiment 3

[0025] A connection method for a main steel frame node device of a tower-type supercritical boiler, the connection nodes of the vertical support are connected by means of hinged connection nodes, so that the section of the vertical support becomes a box-shaped section, and the vertical support section is a 1.2mX1.2m box-shaped, Connect the main column connection nodes in the columns of the support by way of partial rigid connection connection nodes to make the cross-section of the support a 2.5mX2.5m box shape, and make a group of beams into a box with a width of 1m--1.2m and a height of less than 3m The main beam and the column in a group of beams are connected by rigid joints to form the main steel frame.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com