Logistics box-free shell delivery logistics frame

A technology of logistics box and shell, applied in the field of shell delivery logistics rack, can solve the problems of scratches on the surface layer of the lampshade, uneven surface, side end cracks, etc., and achieve the effect of avoiding stacking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

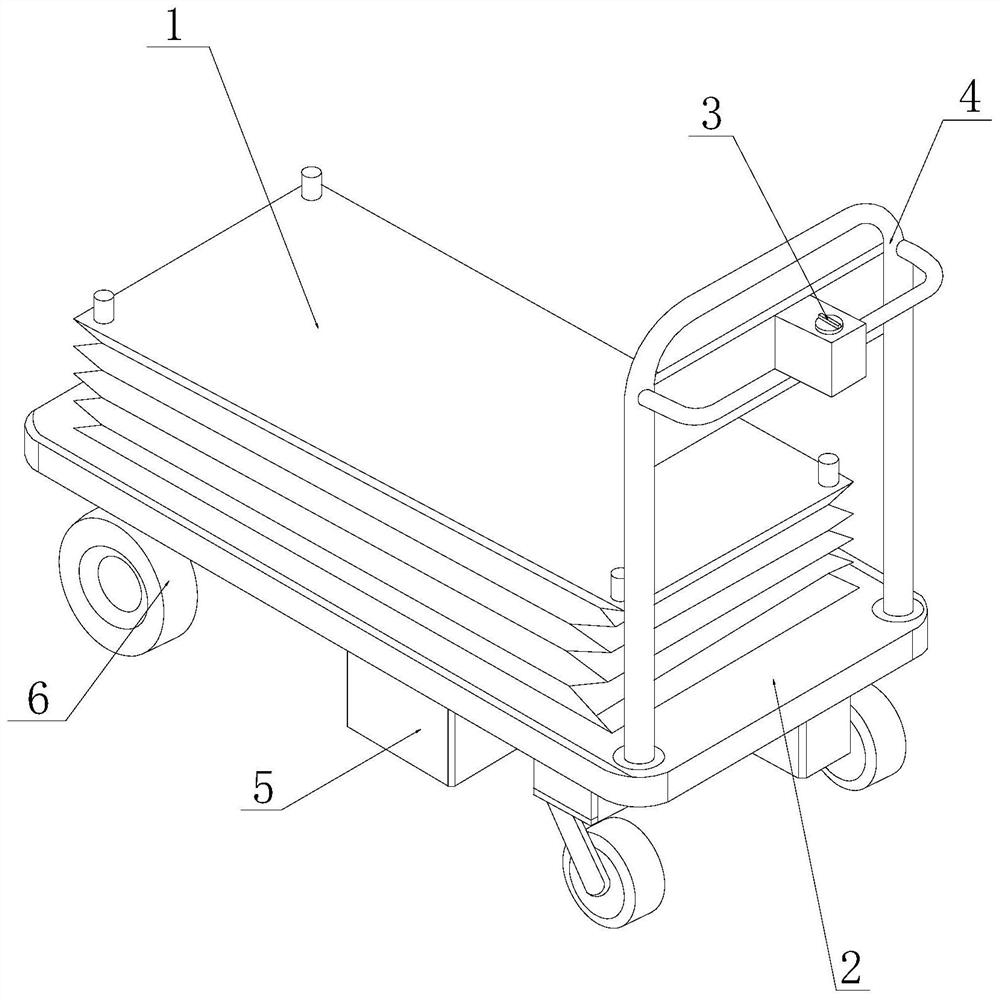

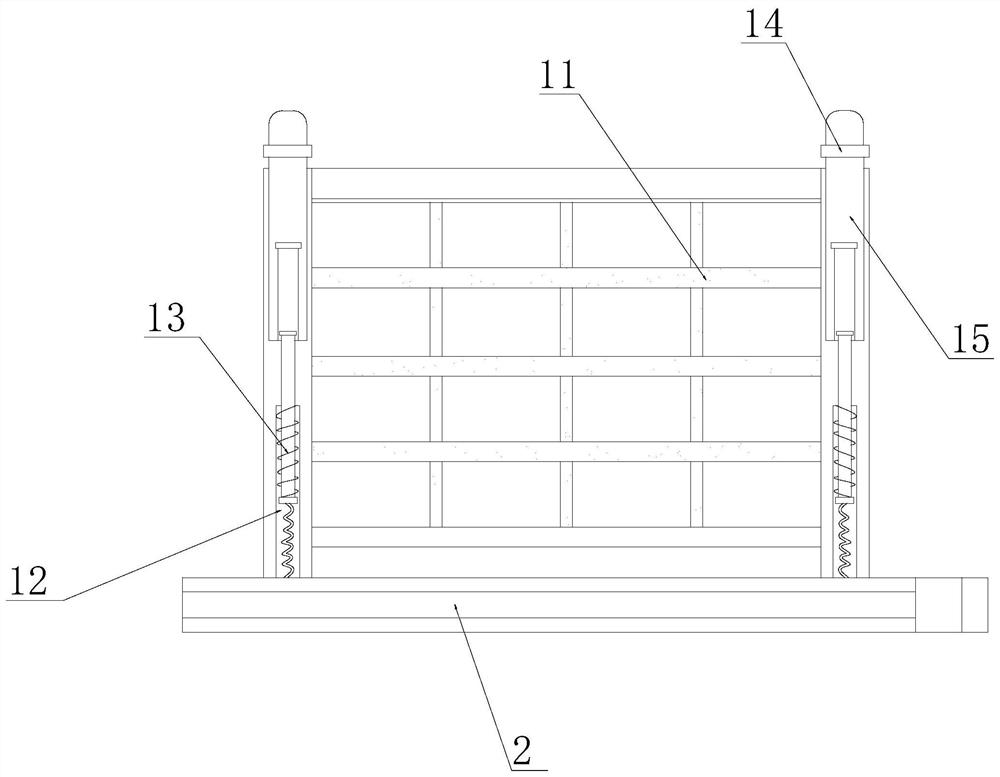

[0026] as attached figure 1 to attach Figure 4 Shown:

[0027] Its structure includes a folding box 1, a loading platform 2, a controller 3, a push rod 4, a storage battery 5, and a driving wheel 6. The lower end of the folding box 1 is embedded and connected to the surface of the loading platform 2, and the right The side is screwed with the push rod 4, the upper end of the push rod 4 is fixed with the controller 3 by bolts, the controller 3 is in clearance fit with the battery 5, the inside of the battery 5 is movably matched with the drive wheel 6, and the folding box 1 It includes a folding frame 11, a support rod 12, a threaded rod 13, a slip-limiting hoop 14, and a sleeve rod 15. Together, the slip limiting hoop 14 is in clearance fit with the internal threaded rod 13, the threaded rod 13 is spirally connected with the inner wall of the support rod 12, and the support rod 12 is nested with the sleeve rod 15 as a whole.

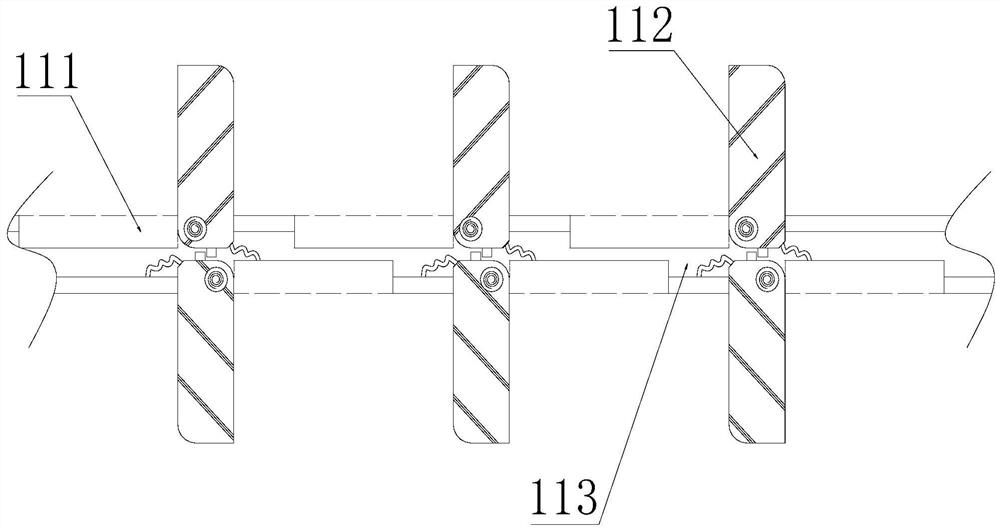

[0028] Wherein, the folding frame 11 includes ...

Embodiment 2

[0033] as attached Figure 5 to attach Figure 7 Shown:

[0034] Wherein, the loading frame a3 includes a chute a31, an opener a32, a sliding buckle a33, and a fixing rod a34. The left end of the opening and closing device a32 is embedded and connected, and the opening and closing device a32 is movably matched with the fixed rod a34. The surface of the fixed rod a34 is embedded and connected with the chute a31. For active cooperation, the interior cooperates with the opener a32 to expand it, wherein the opener a32 is beneficial to expand its internal space to provide a loading space after the sliding buckle a33 is displaced.

[0035]Wherein, the opening and closing device a32 includes a force-bearing block b21, an unfolding frame b22, a folding plate b23, and a storage chamber b24. The anti-folding plate b23 is hingedly connected, and the anti-folding plate b23 is movably matched with the outer end of the storage chamber b24. The storage cavity b24 is presented, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com