Patents

Literature

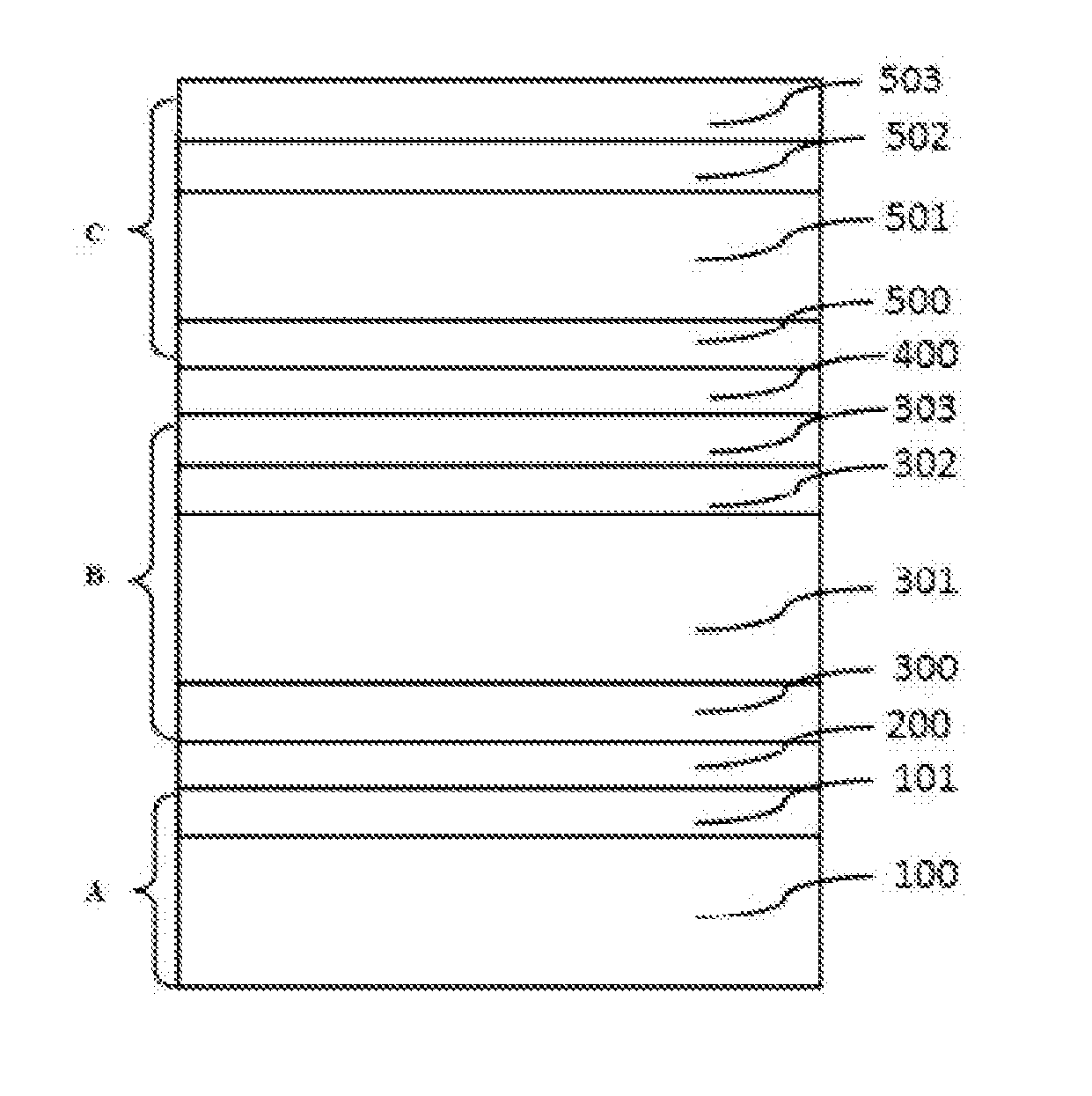

39results about How to "Decrease the filling factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

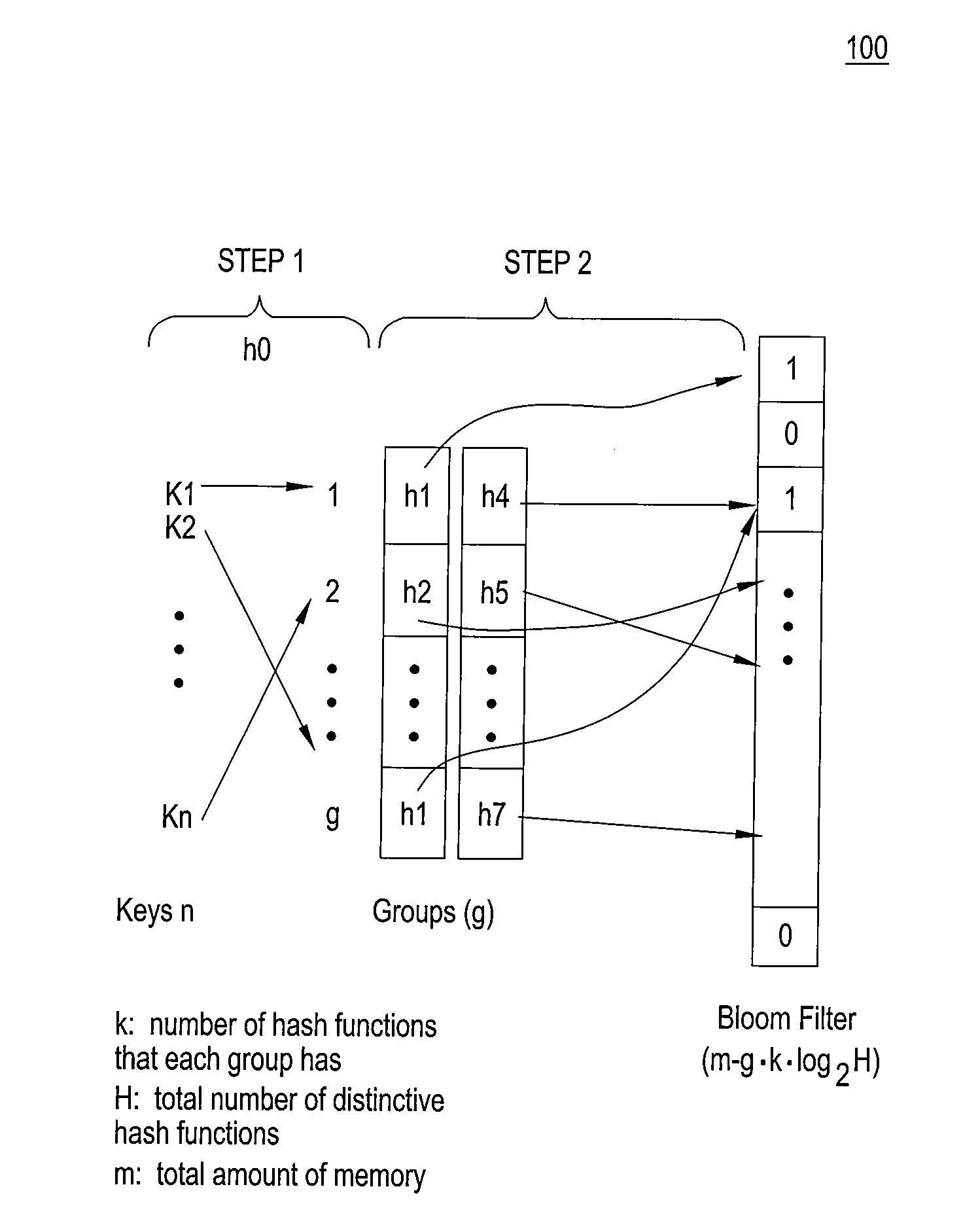

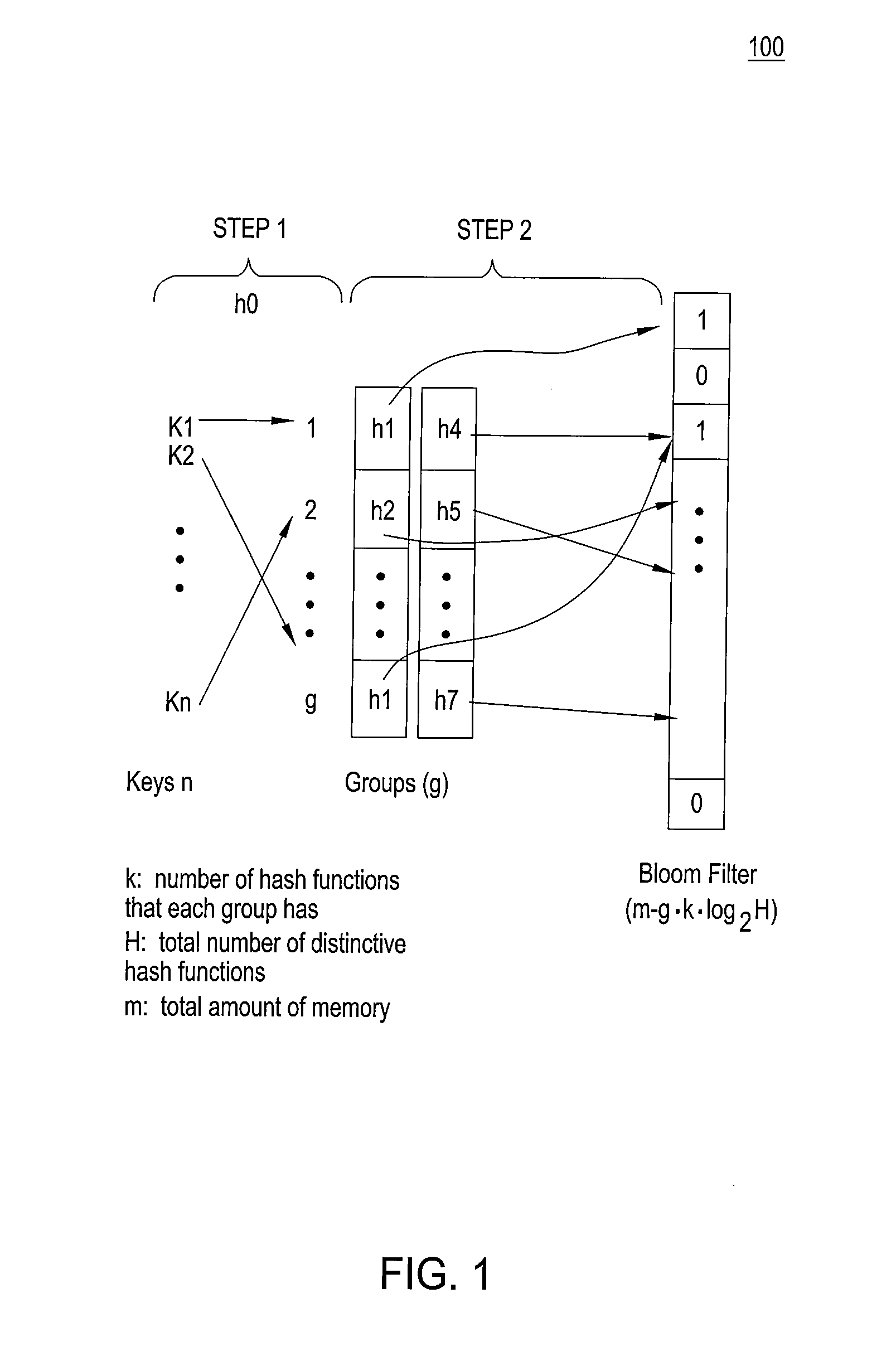

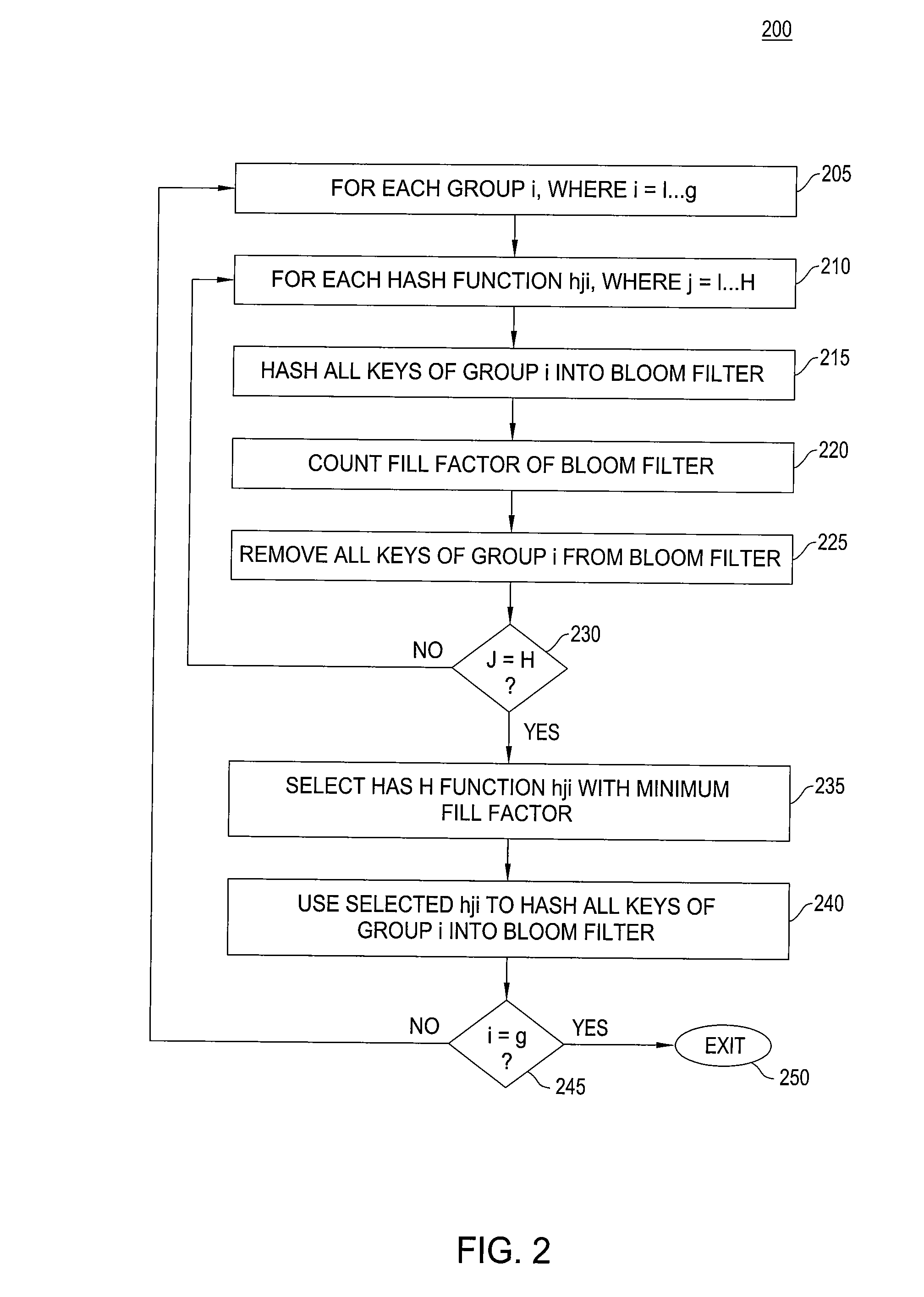

High accuracy bloom filter using partitioned hashing

ActiveUS20080313132A1Reduce false alarm rateReduce the probability of false positivesTransmissionSpecial data processing applicationsHash functionTheoretical computer science

A method and system for generating a bloom filter by mapping into respective groups each of a plurality of initial keys according to a first hash function and mapping each group hashed key into a bloom filter using k respective hash functions.

Owner:ALCATEL-LUCENT USA INC

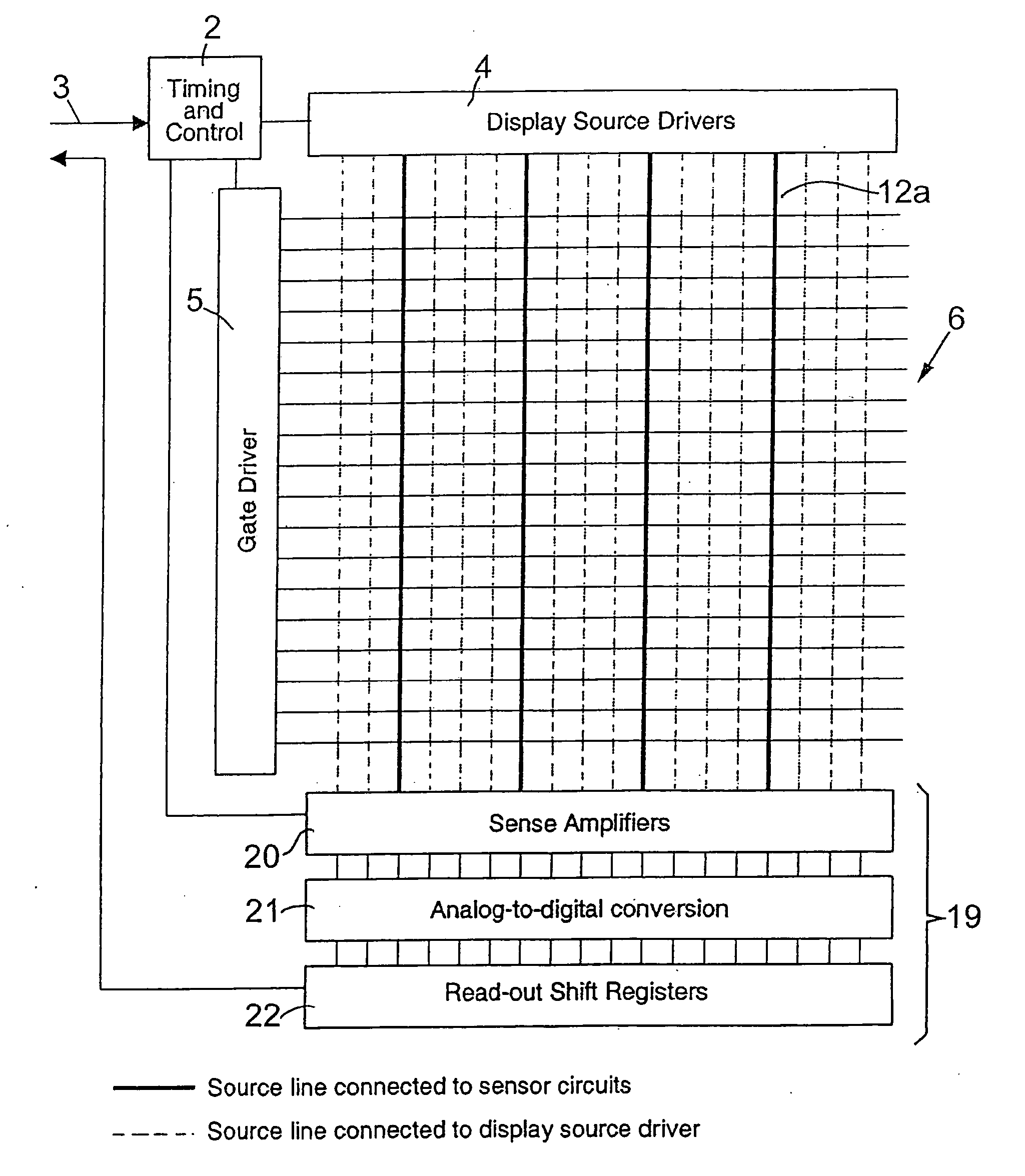

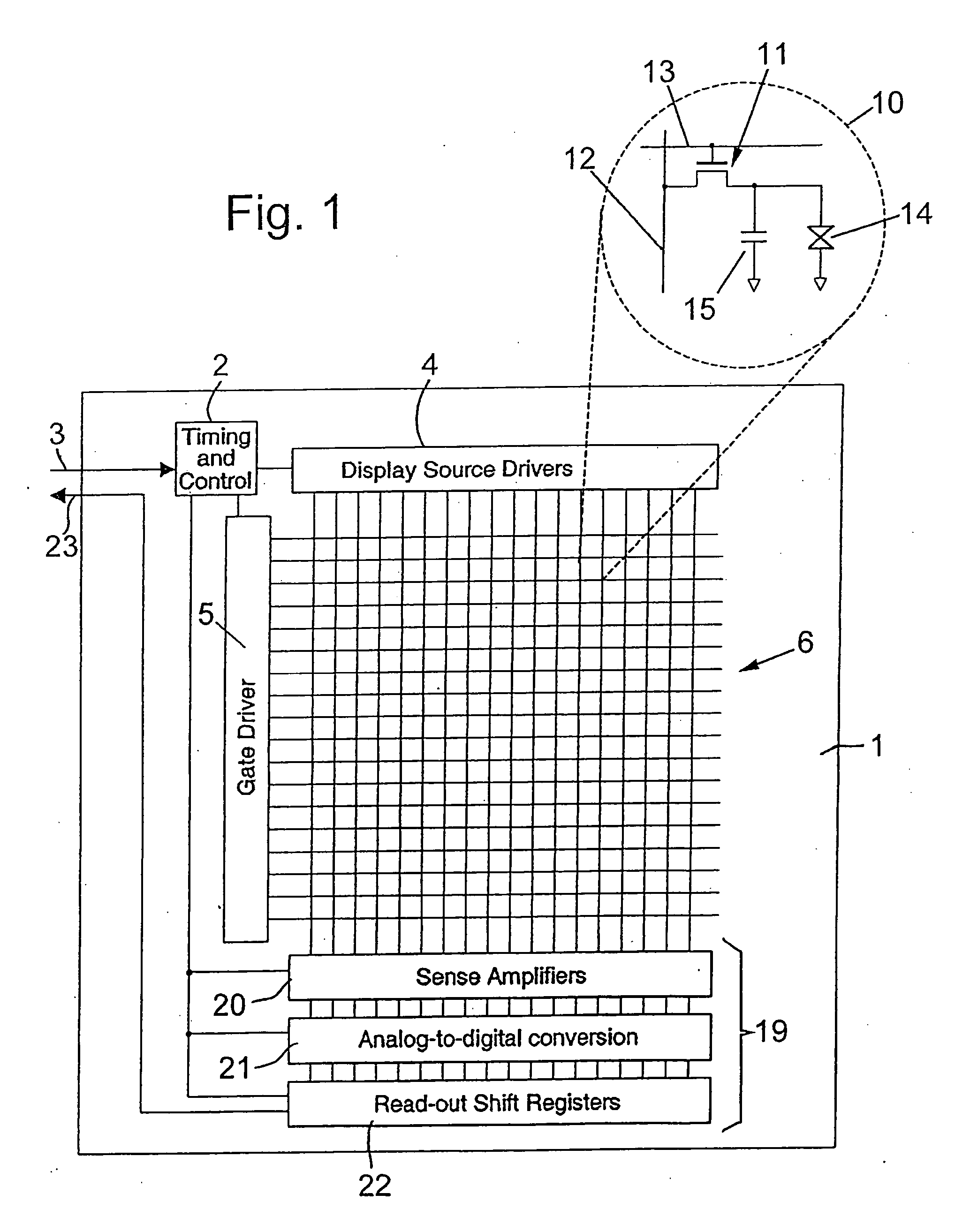

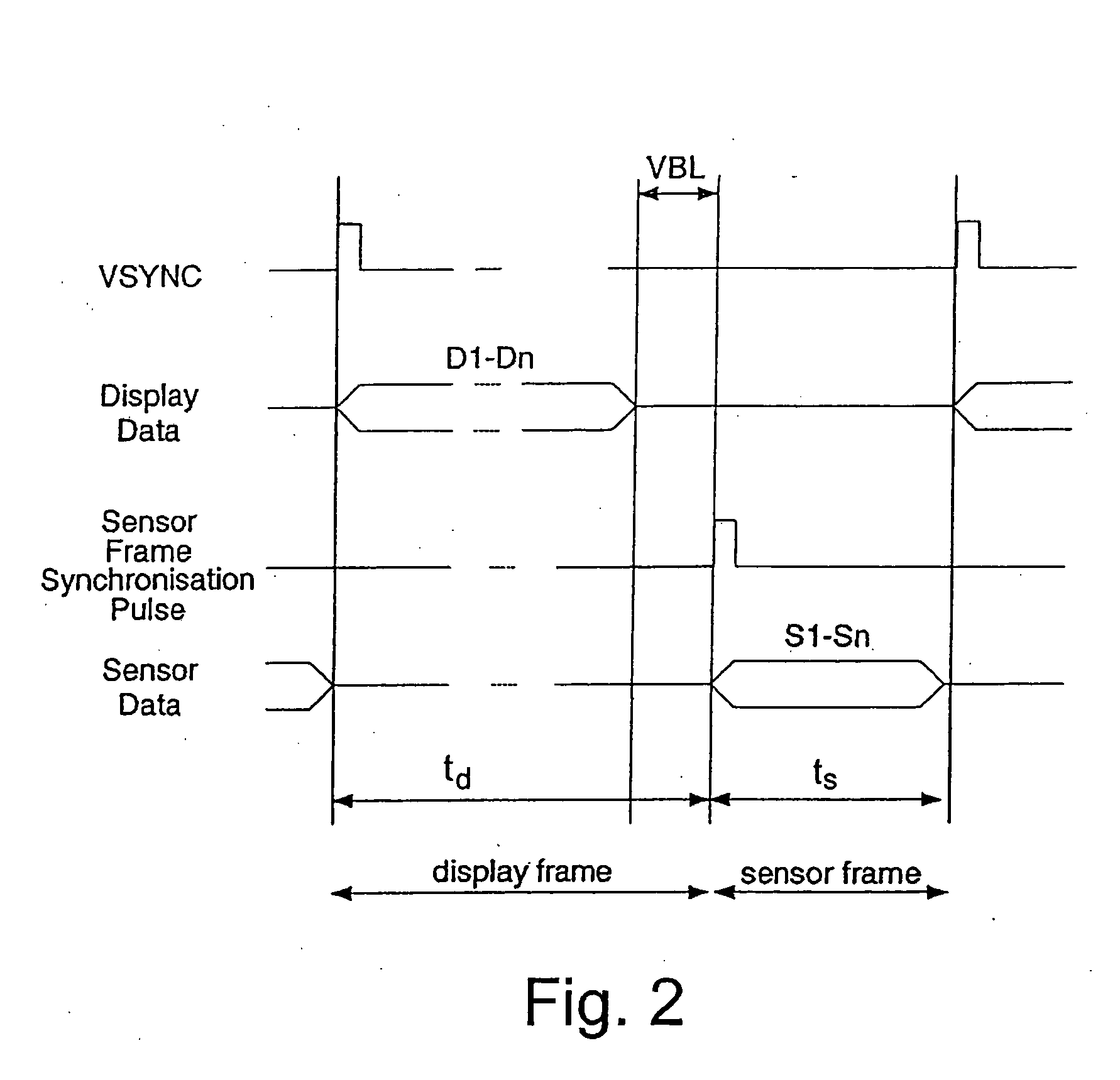

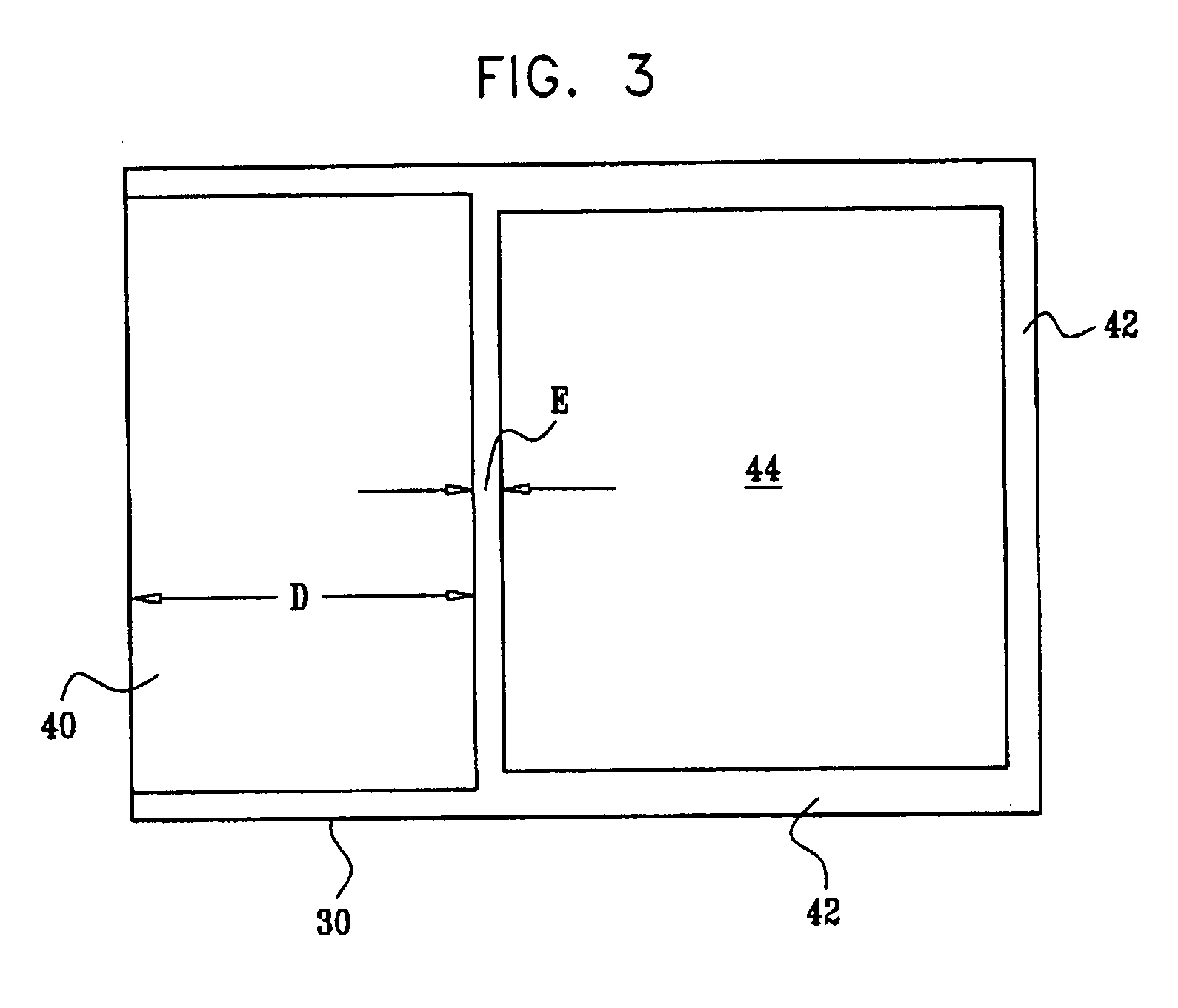

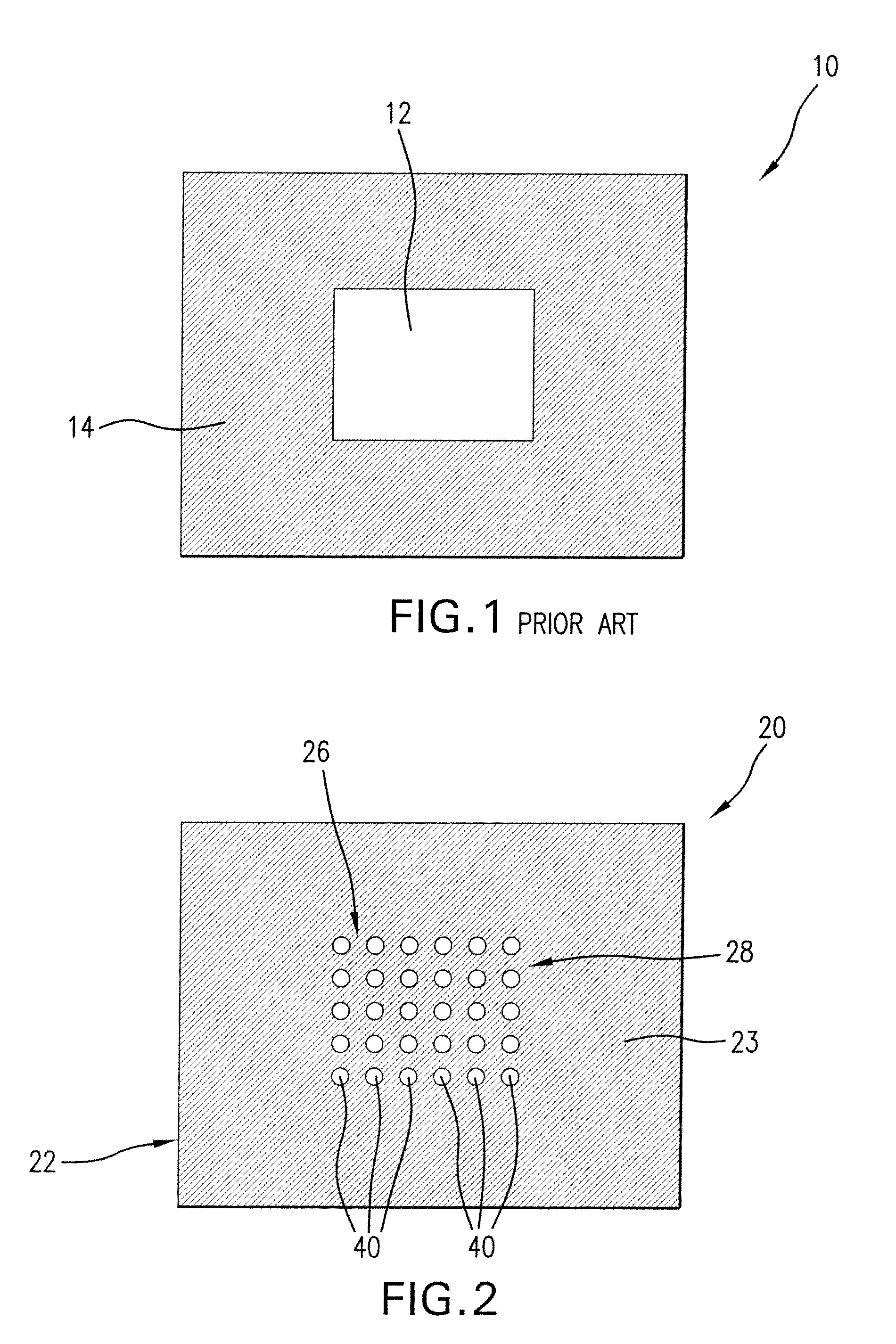

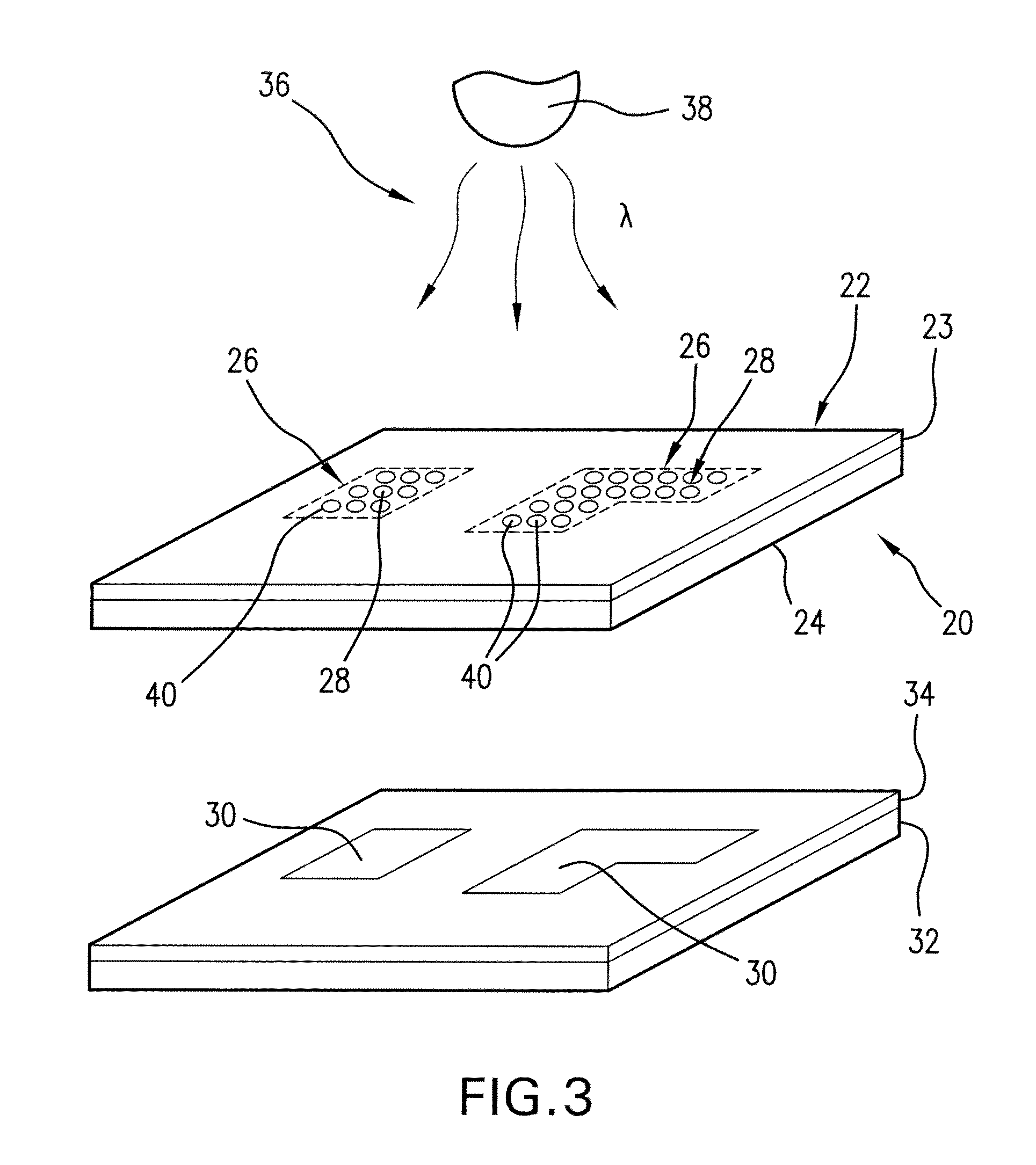

Display and sensor apparatus

InactiveUS20040227743A1Reduced pixel apertureDecrease the filling factorCathode-ray tube indicatorsMetal working apparatusAudio power amplifierActive matrix

An apparatus is provided which integrates sensor functionality with an active matrix display such as an AMLCD. A conventional active matrix 6 of LCD pixels 10 is provided with standard display source and gate drivers 4 and 5. The display source driver 4 supplies data signals for generating the required pixel response to column electrodes 12 which are also connected to an output arrangement 19 including sense amplifiers 20. During a display phase of operation, the AMLCD operates conventionally with the matrix 6 being refreshed a row at a time and frame by frame. Between frames, the sense amplifiers 20 are enabled and the matrix 6 is again scanned by the gate driver 5. The characteristics of each pixel represent an external stimulus which is sensed by the relevant sense amplifier 20 and supplied at an output 23 of the arrangement.

Owner:SHARP KK

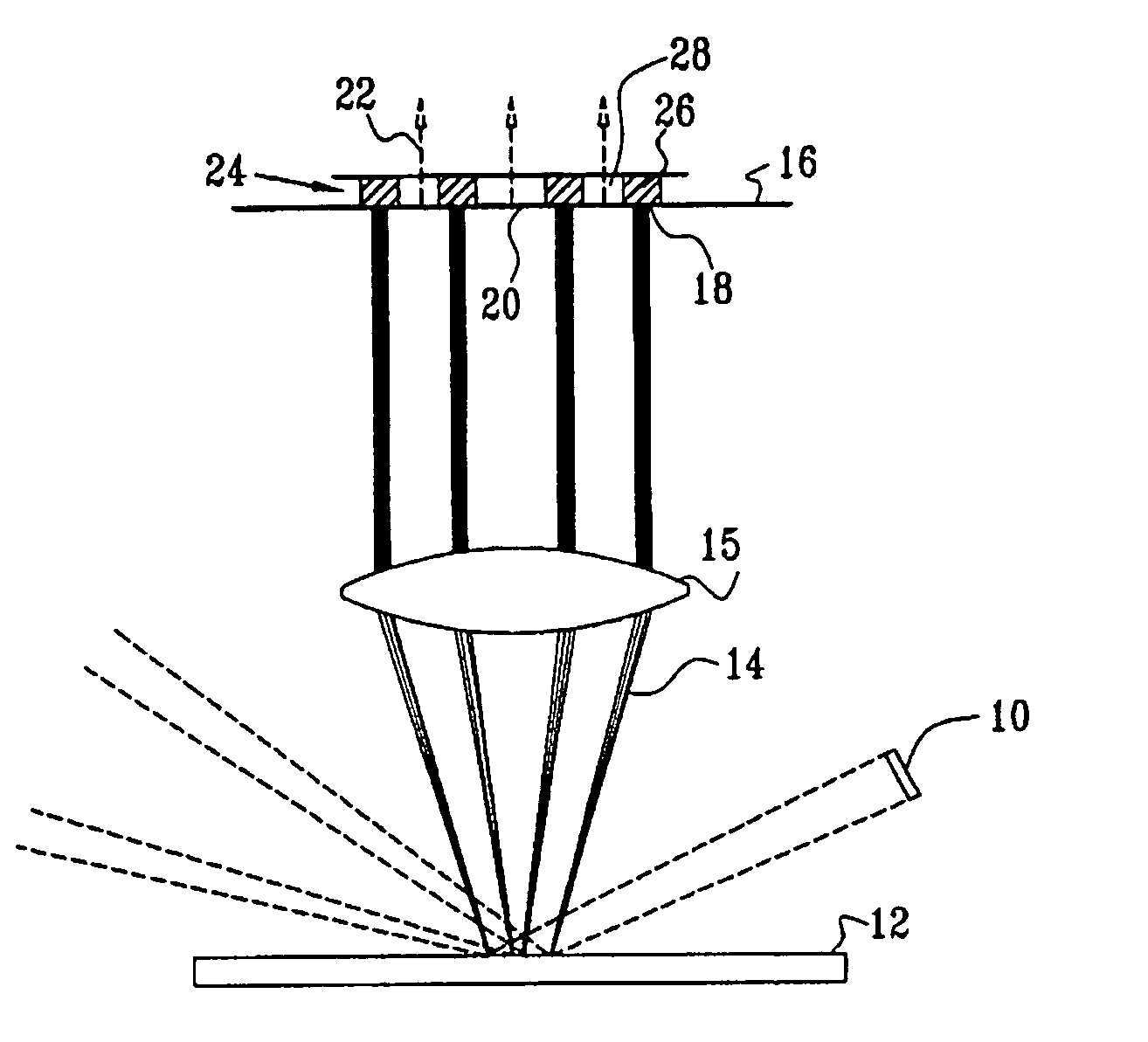

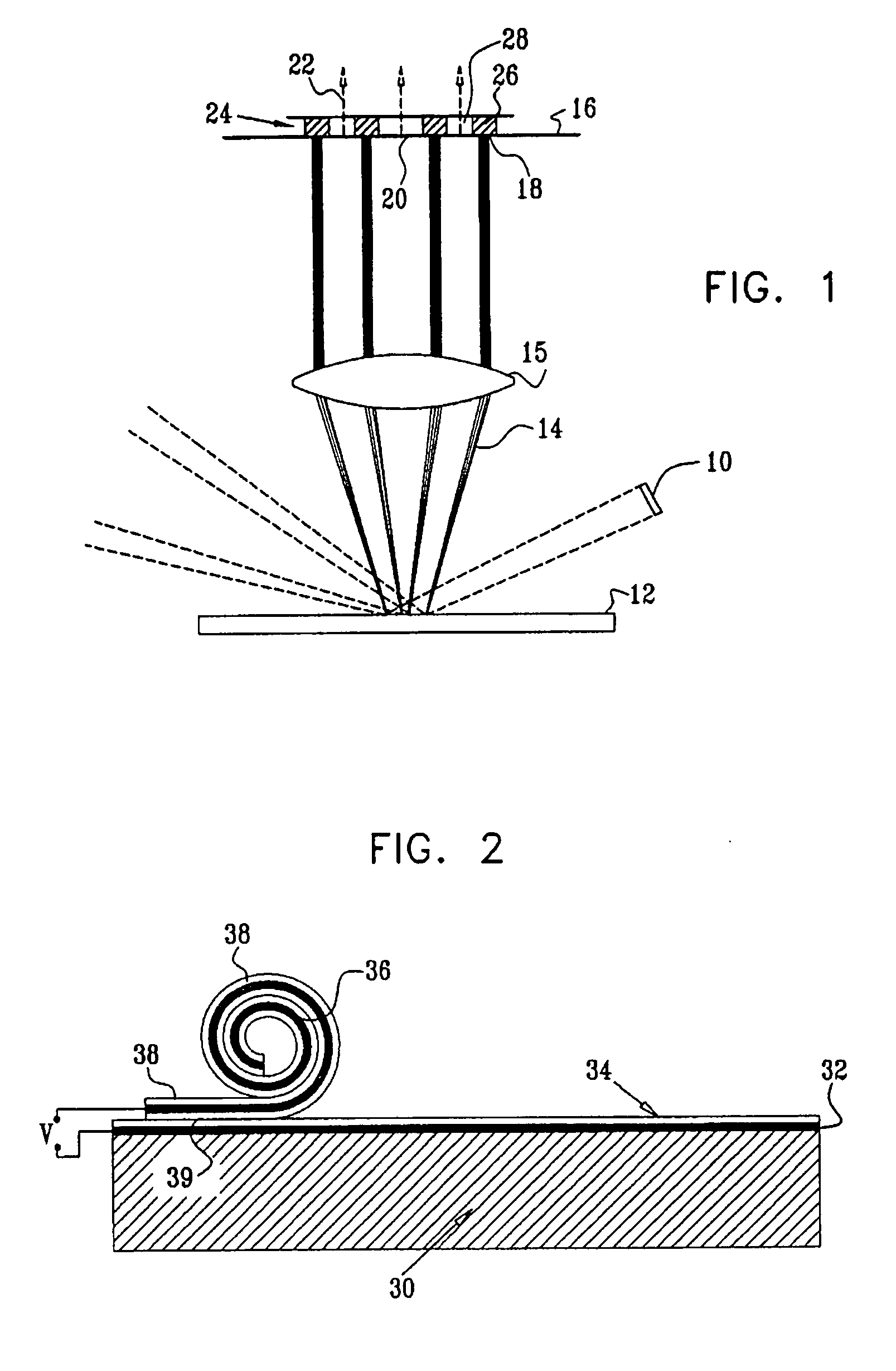

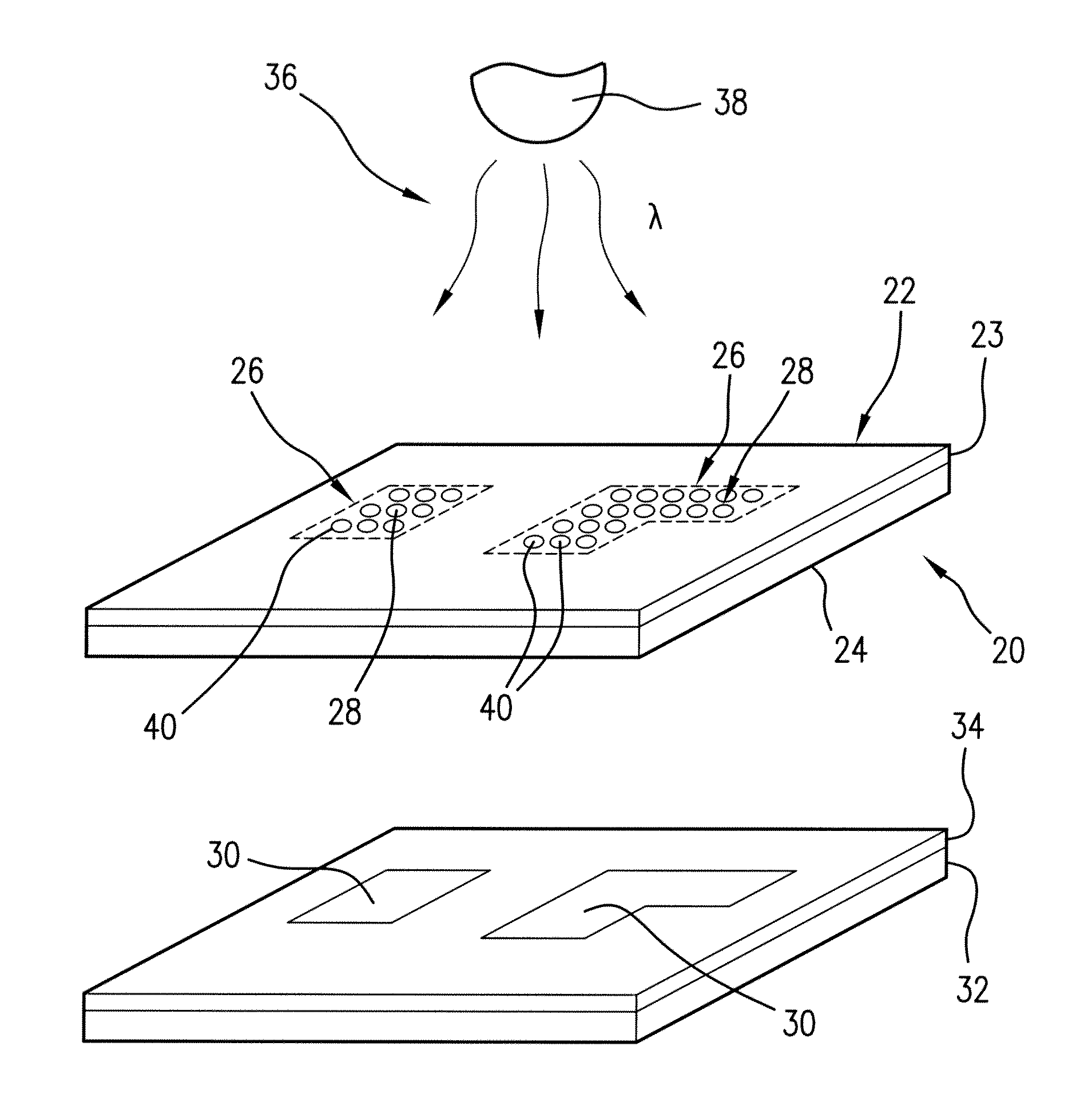

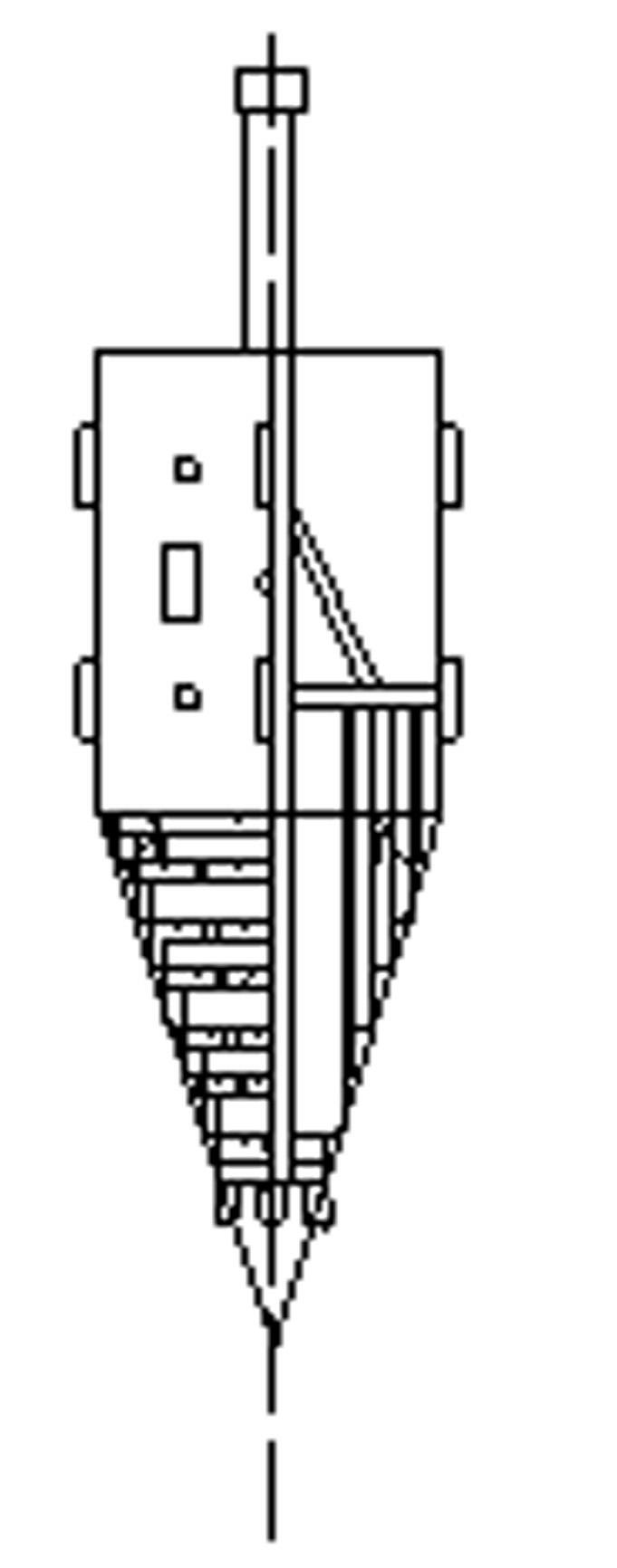

Programmable spatial filter for wafer inspection

InactiveUS20060012781A1Improve fill factorFacilitate transmissionOptically investigating flaws/contaminationSpatial light modulatorLight beam

A programmable spatial filter for use as a Fourier plane filter in dark field wafer inspection systems, based on the use of MEMS (Micro-Electro-Mechanical Systems) devices. In comparison with prior art systems, especially those using LCD's, the use of MEMS devices provide a number of potential advantages, including good transmission in the UV, a high fill factor, polarization independence and a high extinction ratio since the shutter is opaque when closed. The MEMS devices can be flap devices, artificial eyelid, or double shutter devices. Additionally, a novel spatial light modulator (SLM) assembly having a double layer of SLM arrays is described, in which the fill factor is increased in comparison to a single layer SLM using the same devices, by positioning the dead areas of the elements of both arrays collinearly in the modulated beam. This SLM assembly can be implemented using pixelated LCD arrays or MEMS arrays.

Owner:NEGEVTECH

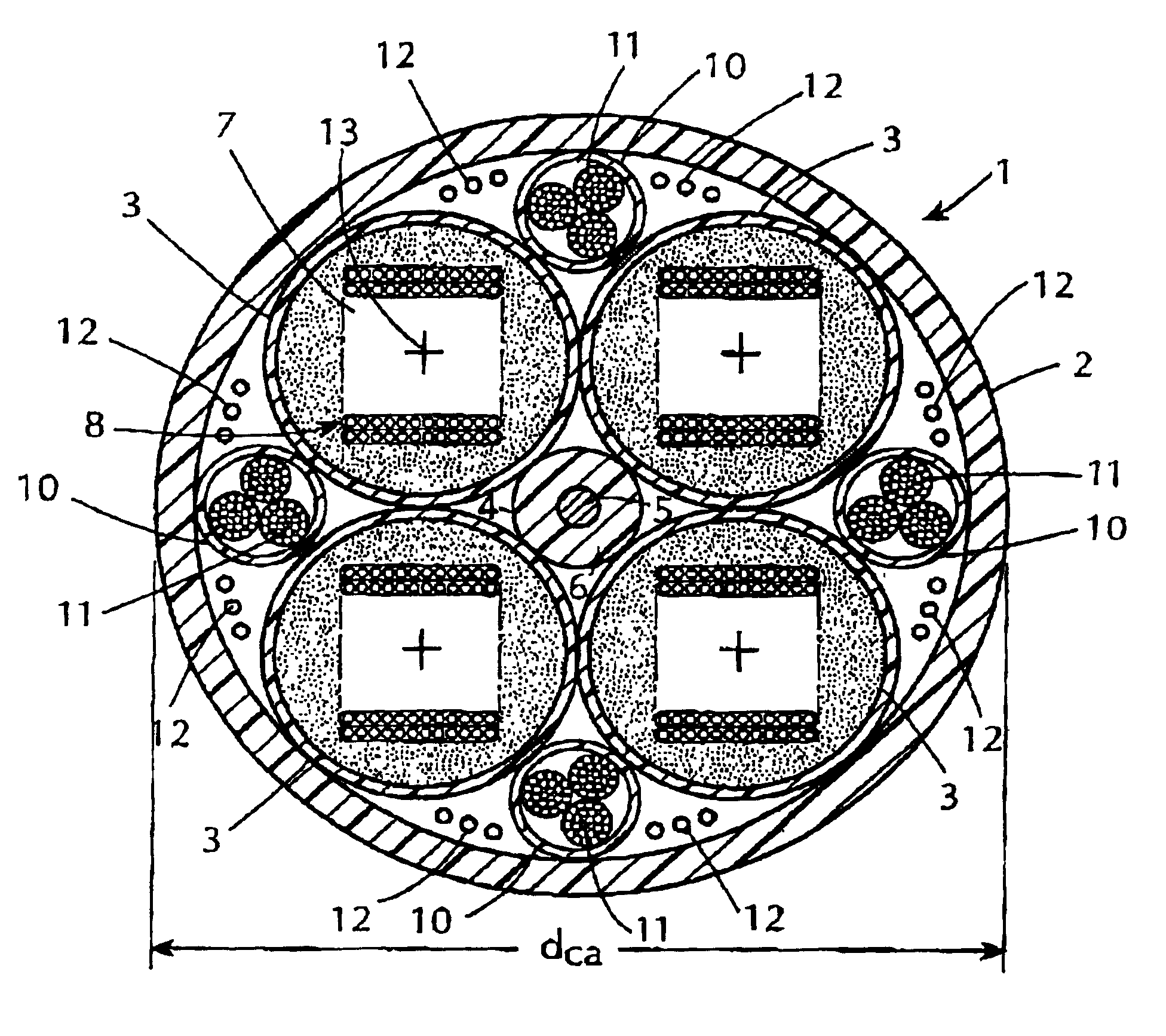

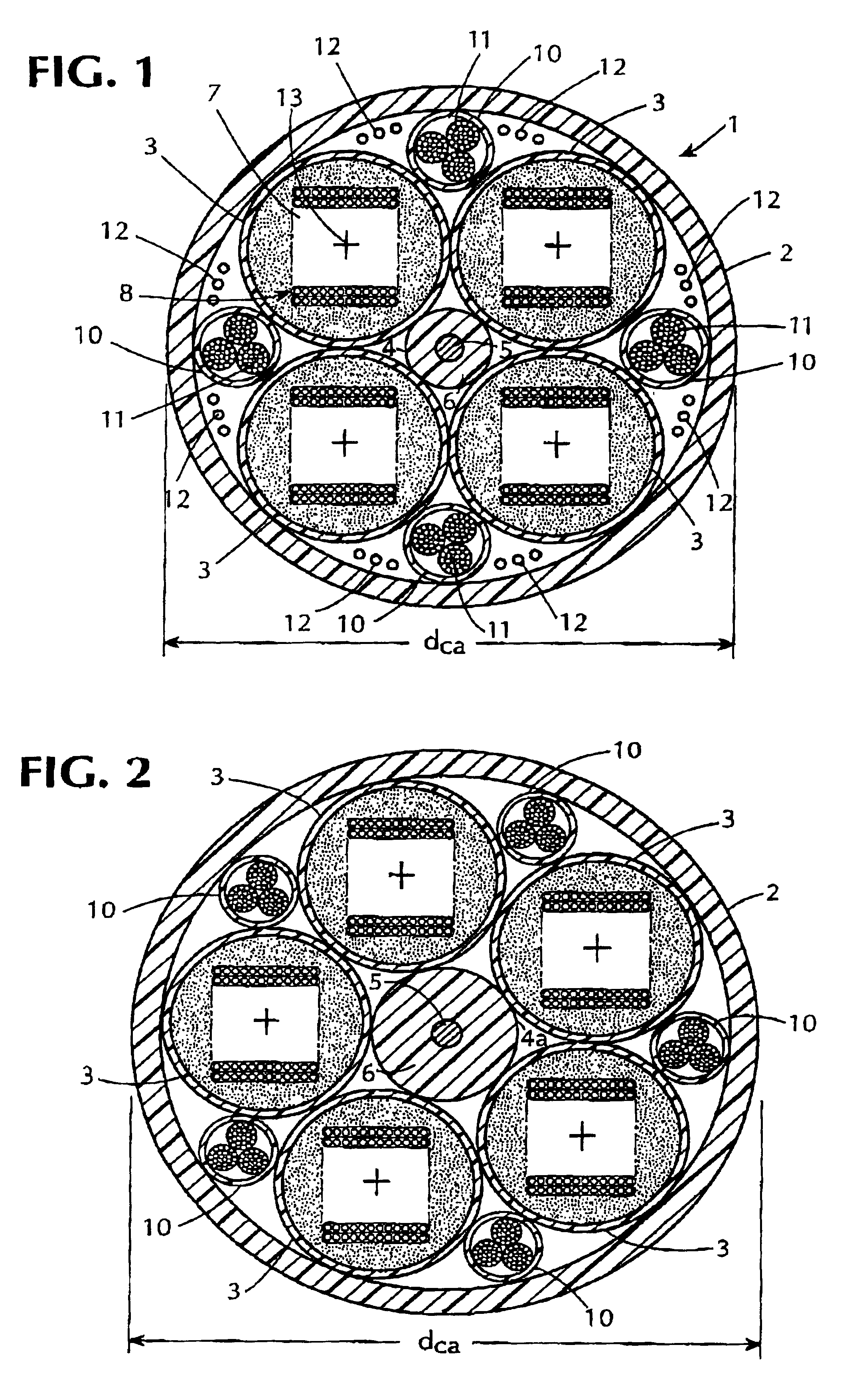

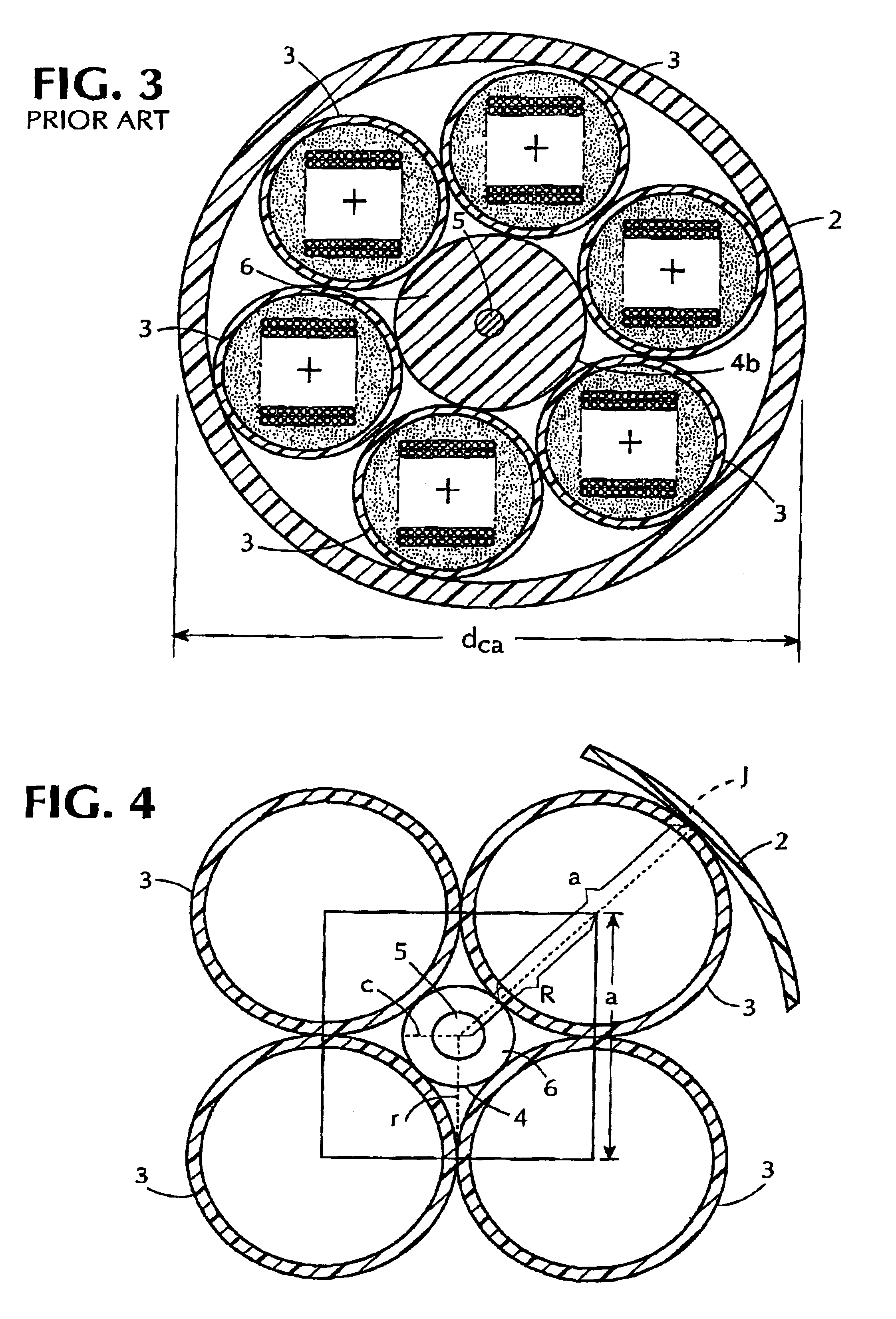

High fiber count optical fiber cable with buffer tubes around central strength member

InactiveUS6870995B2Increase the number ofReduce the overall diameterFibre mechanical structuresFiberFill factor

Optical fiber cable with a central strength member structure and with four or five buffer tubes each loosely receiving optical fiber ribbons in a stack and is disposed around and contacting the strength member. The optical fiber count is in excess of 1000 and the fill factor is not greater than 85% in a two inch duct. Each buffer tube contacts adjacent buffer tubes, and the buffer tubes are encircled by a jacket. Optionally, spaces bounded by pairs of buffer tubes and the jacket have optical fibers therein and can also include flexible longitudinal strength members and / or water blocking filaments. Preferably, the strength member structure and / or the buffer tubes are encircled by a water blocking tape. The optical fiber ribbons in the stacks can include different numbers of fibers, and hence, can have different width.

Owner:PRYSMIAN COMM CABLES & SYST USA LLC

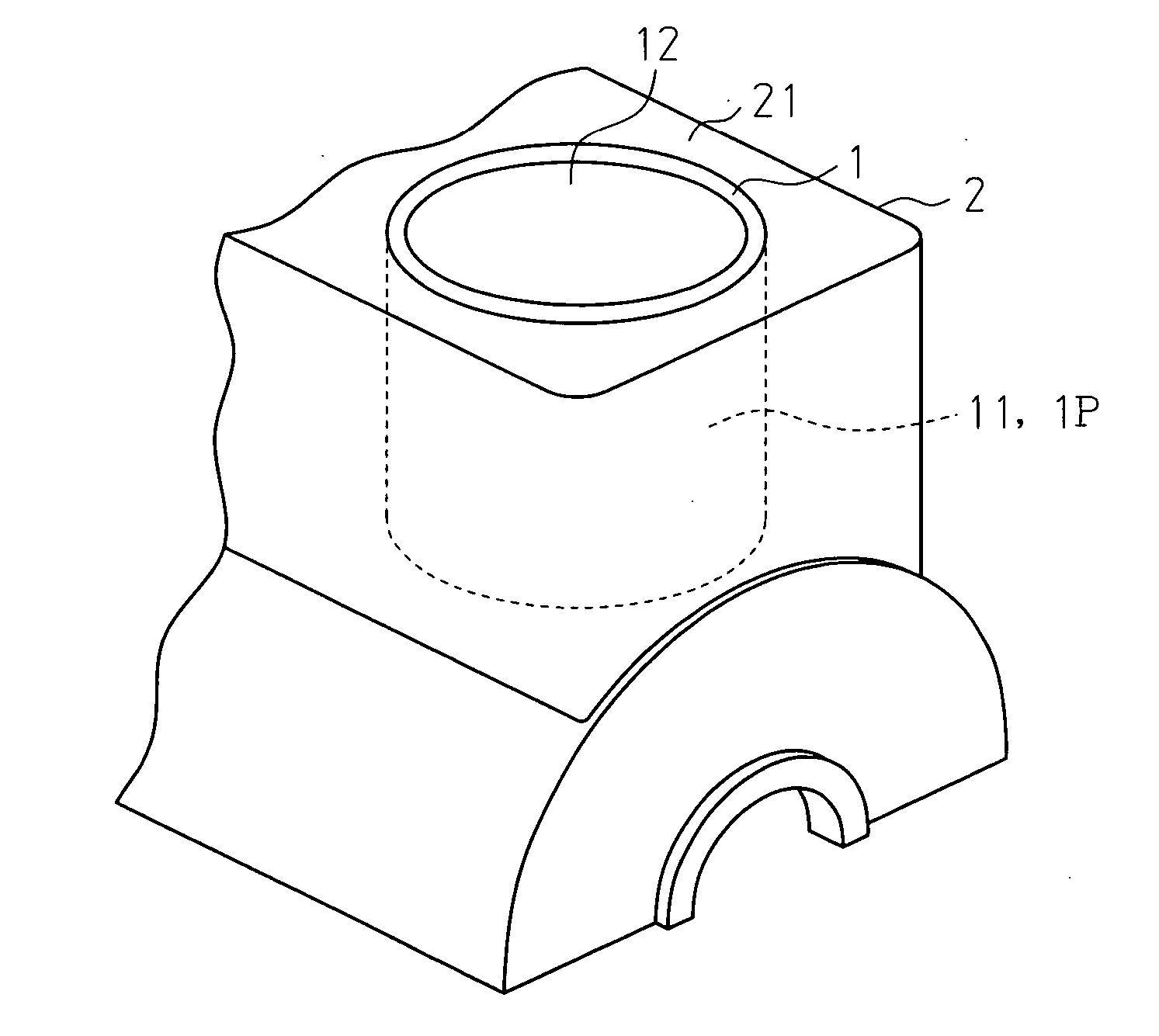

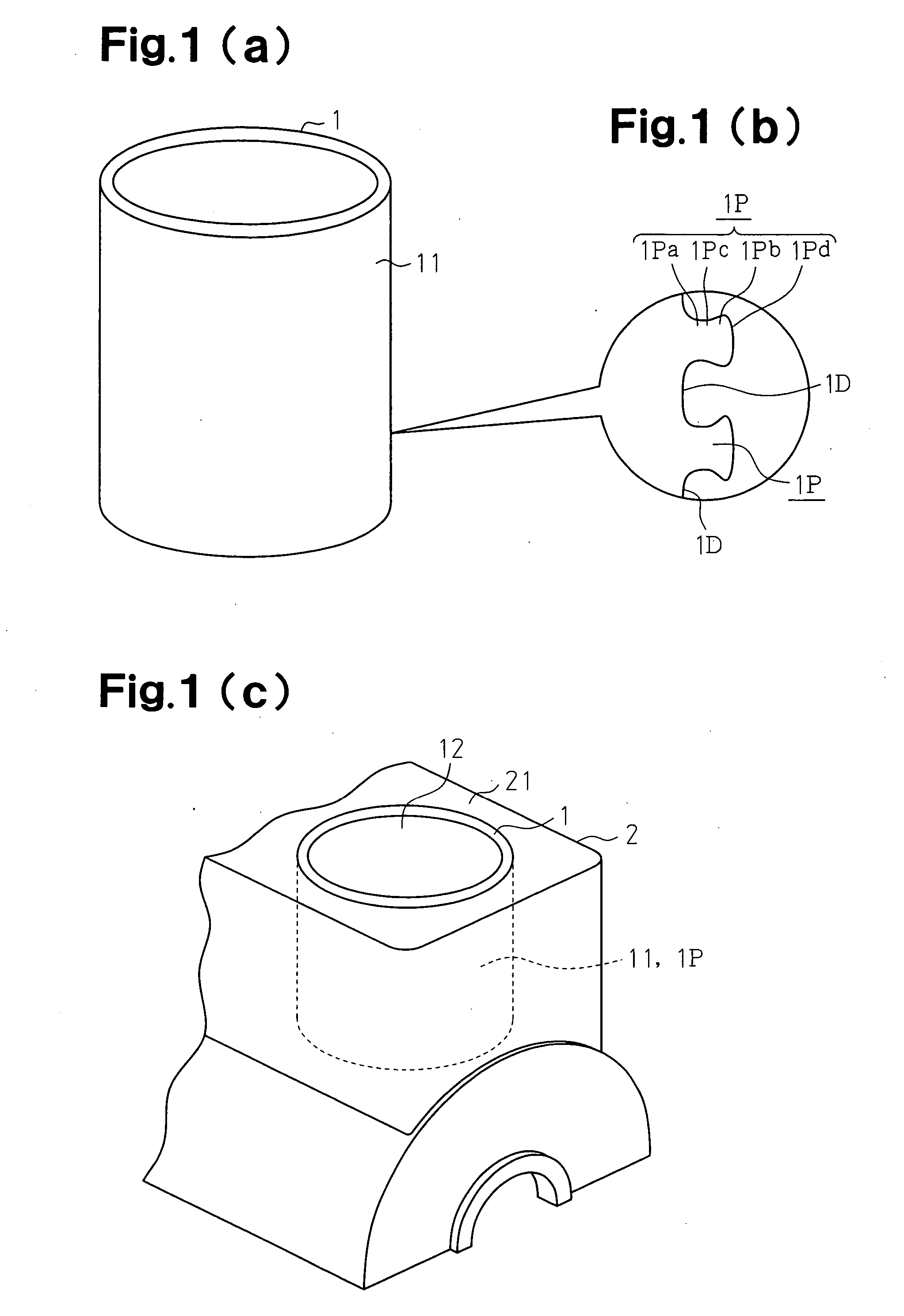

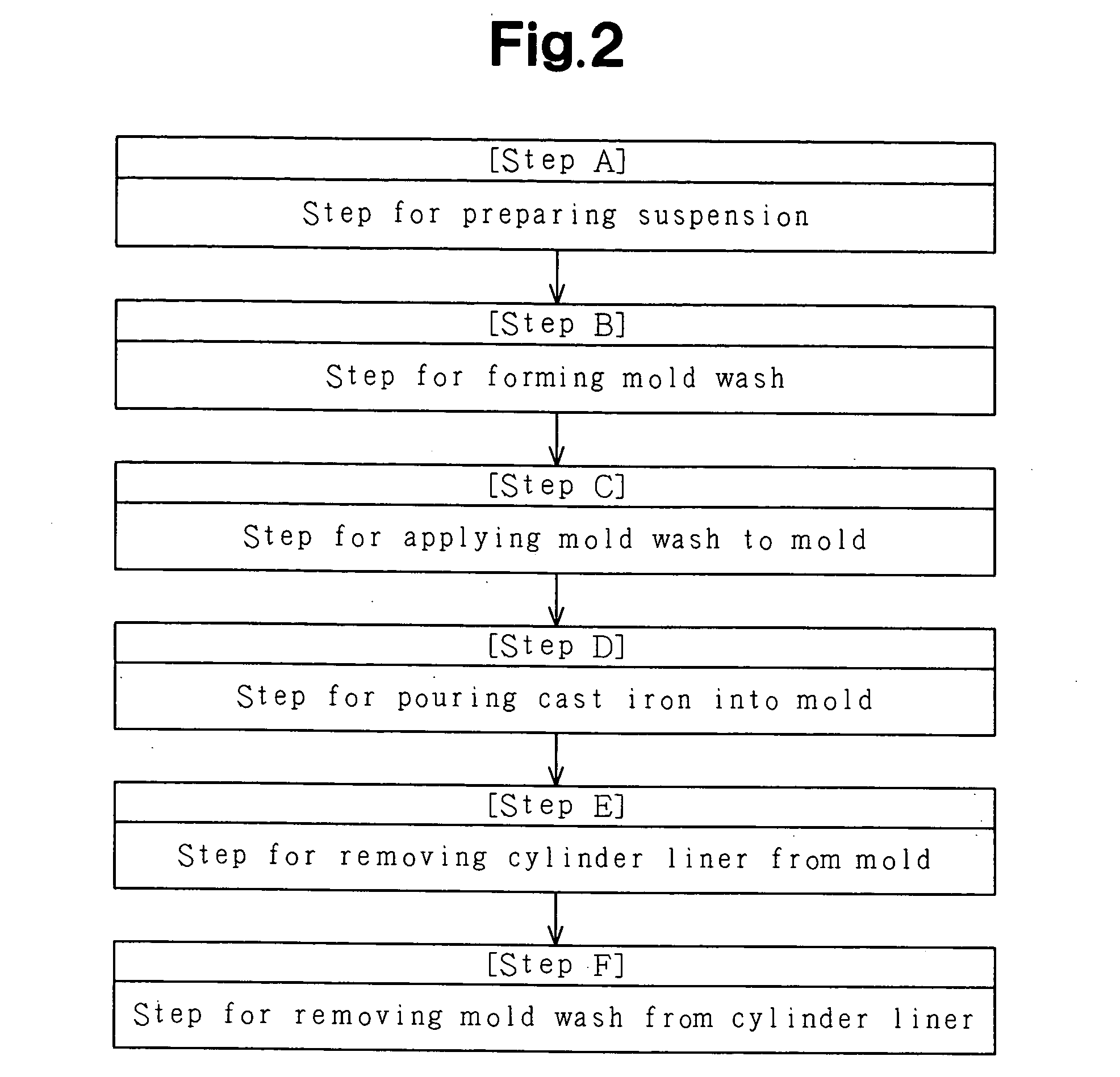

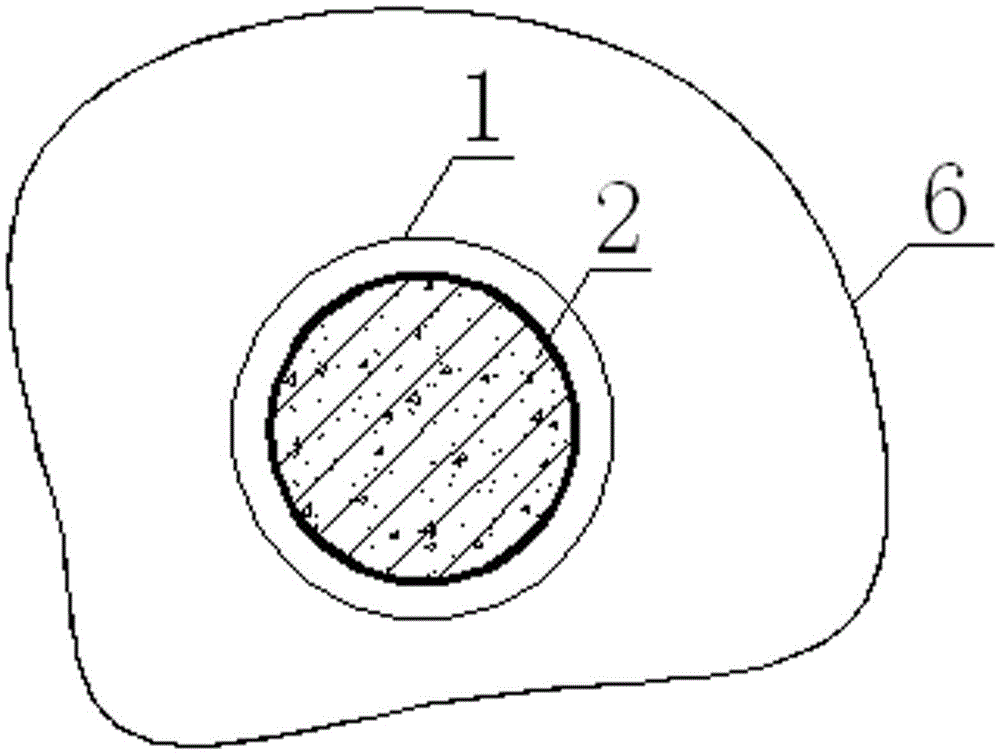

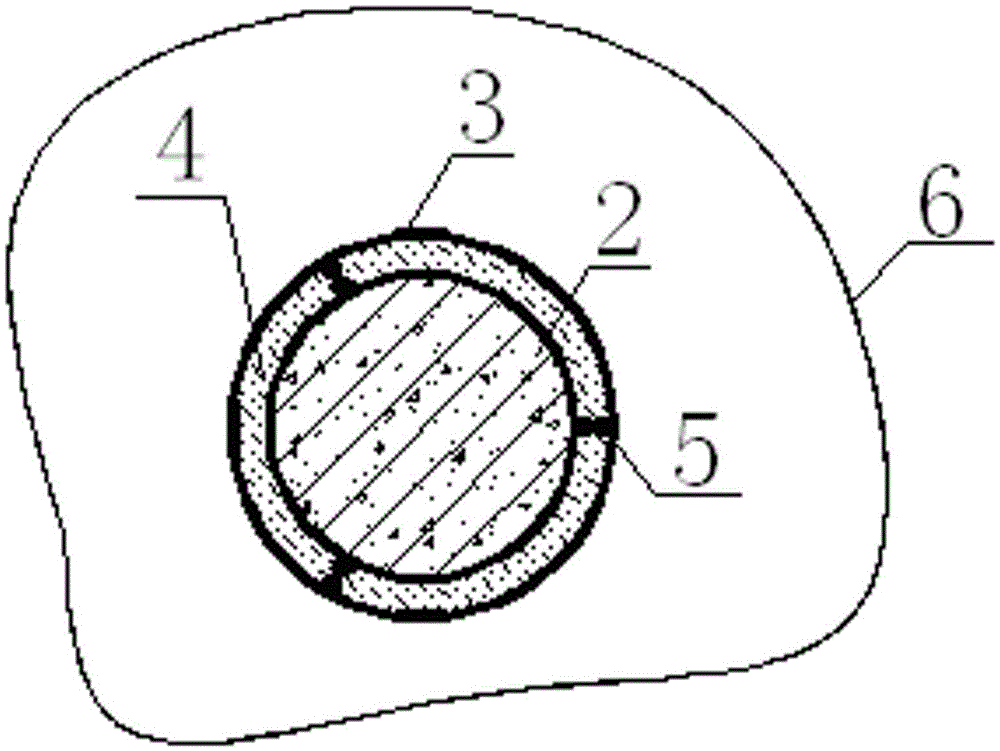

Cylinder Liner for Insert Casting and Method for Manufacturing Thereof

ActiveUS20070240652A1Reduce work efficiencyDecrease the filling factorCylinder headsFoundry mouldsCylinder blockArea ratio

A cylinder liner for insert casting and a method for manufacturing the cylinder liner are provided. The cylinder liner and the method are applied to cylinder blocks and improve the adherence and the bonding strength with a cylinder block material in a favorable manner. The cylinder liner satisfies the following requirements: (i) the height of projections 1P is in a range between 0.5 mm and 1.0 mm, inclusive; (ii) the number of the projections 1P is in a range between 5 and 60, inclusive, per cm2 on the outer circumferential surface; (iii) the area ratio of regions each encircled by a contour line of a height of 0.4 mm is in a range between 10% and 50%, inclusive; (iv) the area ratio of regions each encircled by a contour line of a height of 0.2 mm is in a range between 20% and 55%, inclusive; (v) the region each encircled by a contour line of the height of 0.4 are independent from each other; and (vi) the area of the regions each encircled by a contour line of the height of 0.4 mm is in a range between 0.2 mm2 and 3.0 mm2, inclusive.

Owner:TEIPI IND +2

High-concentration multi-junction solar cell and method for fabricating same

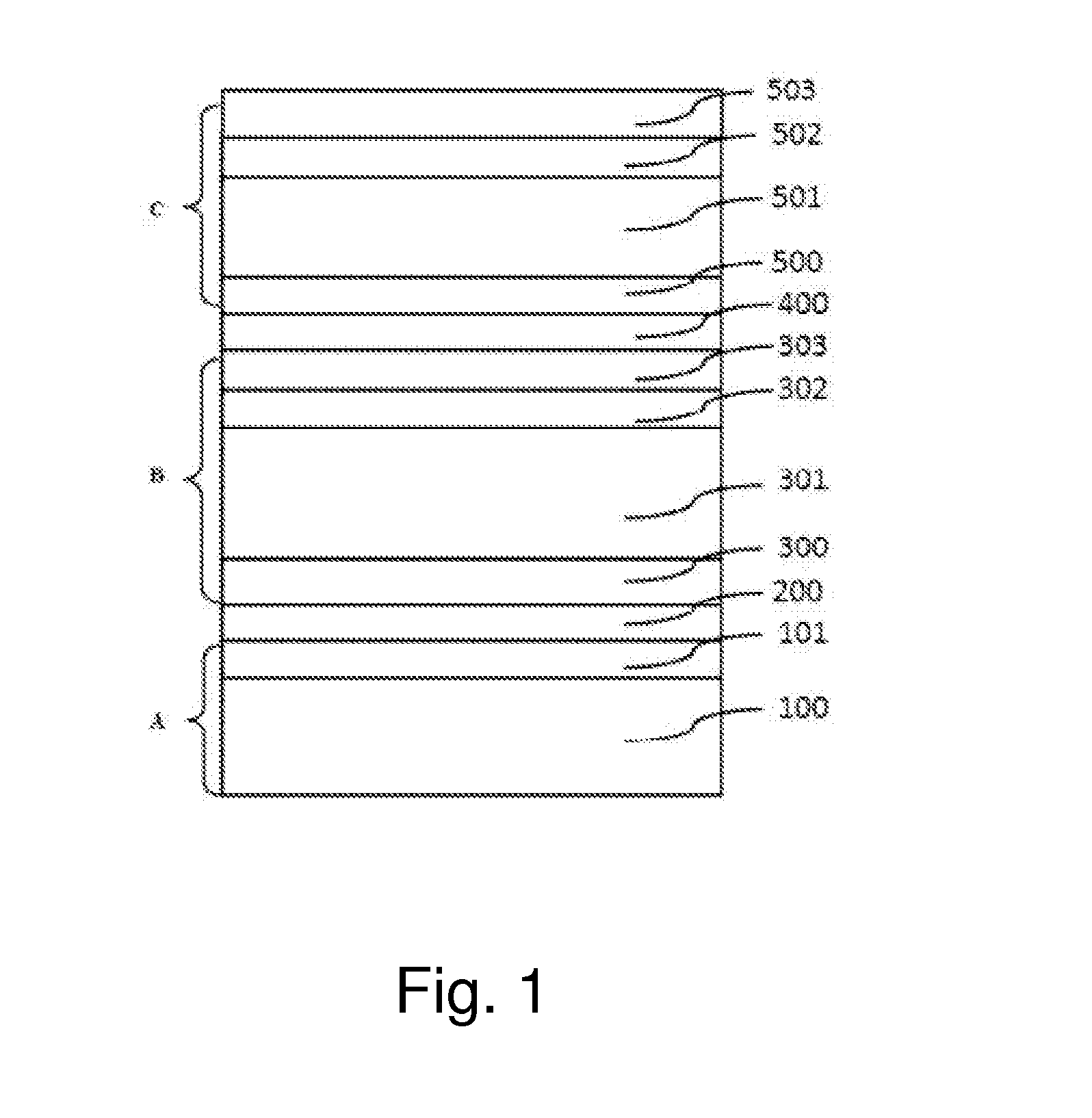

InactiveUS20140090700A1High Photoelectric Conversion EfficiencyGreat series resistanceFinal product manufactureSemiconductor/solid-state device manufacturingHigh concentrationFill factor

A high-concentration multi-junction solar cell and method for fabricating same is provided. The high-concentration multi-junction solar cell comprises a top cell, an intermediate cell, a bottom cell and two tunneling junctions connecting the top cell and intermediate cell and the intermediate cell and bottom cell. The emitter layers of the top and intermediate cells both employ the graded doping concentrations and have high open circuit voltage and short circuit current. The top cell emitter layer is over several hundred nanometers thicker than that of the traditional multi-junction cell so as to decrease the whole series resistance of the multi-junction cell, improve the fill factor, and gain higher photoelectric conversion efficiency.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

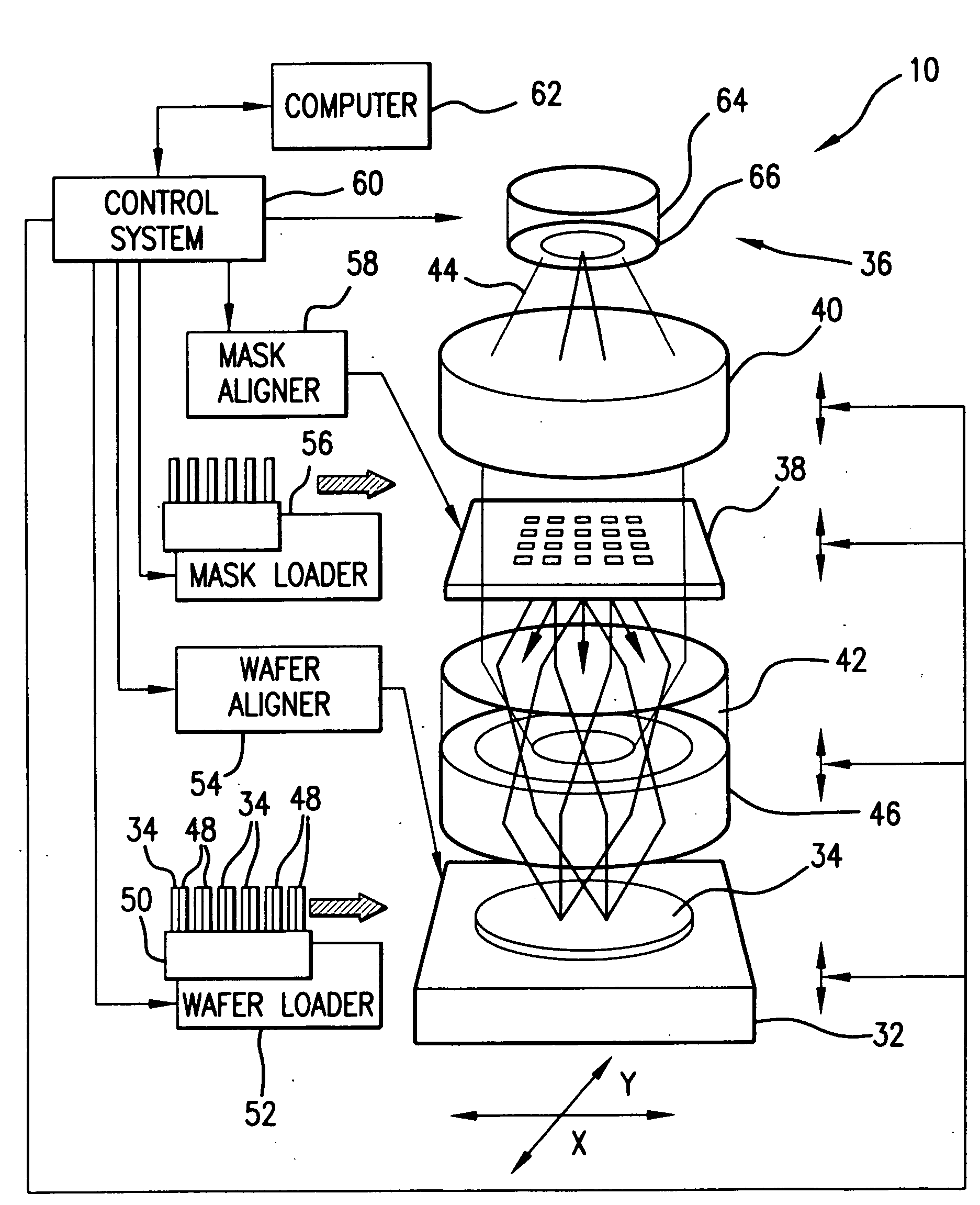

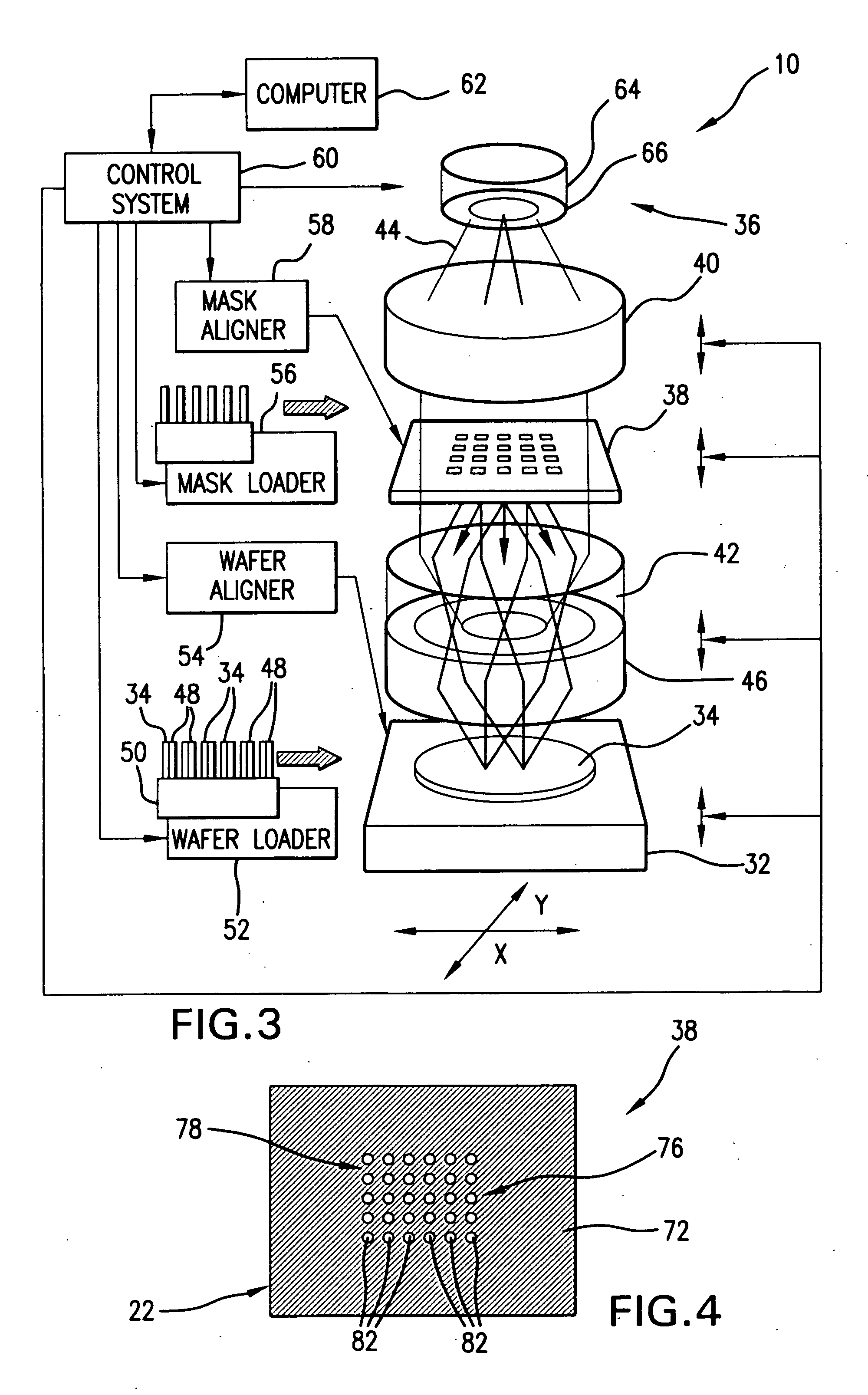

Stepper system for ultra-high resolution photolithography using photolithographic mask exhibiting enhanced light transmission due to utilizing sub-wavelength aperture arrays

ActiveUS20090201475A1High light transmittanceReduce manufacturing costPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistPhotoresist

A stepper system for ultra-high resolution nano-lithography employs a photolithographic mask which includes a layer of an electrically conductive optically opaque material in which periodic arrays of sub-wavelength apertures are formed. The plasmonic excitation in the photolithographic mask exposed to the light of the wavelength in the range of 197 nm-248 nm, produces high resolution far-field radiation patterns of sufficient intensity to expose a photoresist on a wafer. The stepper system demonstrates the resiliency to the mask defects and ability to imprint coherent clear features of nano dimensions (45 nm-500 nm) and various shapes on the wafers for integrated circuits design. The stepper system may be adjusted to image the plane of the highest plasmonic field exiting the mask.

Owner:UNIV OF MARYLAND

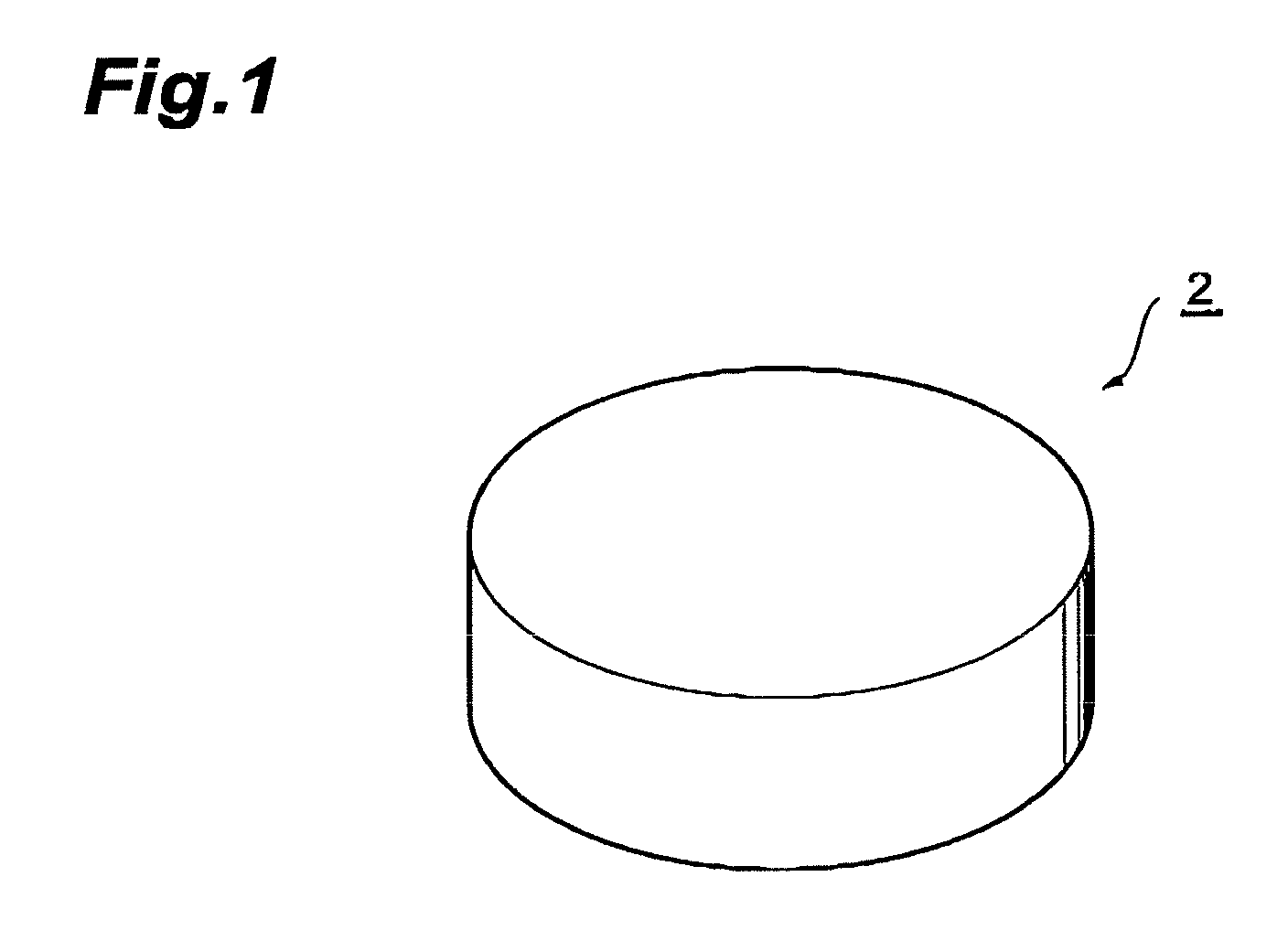

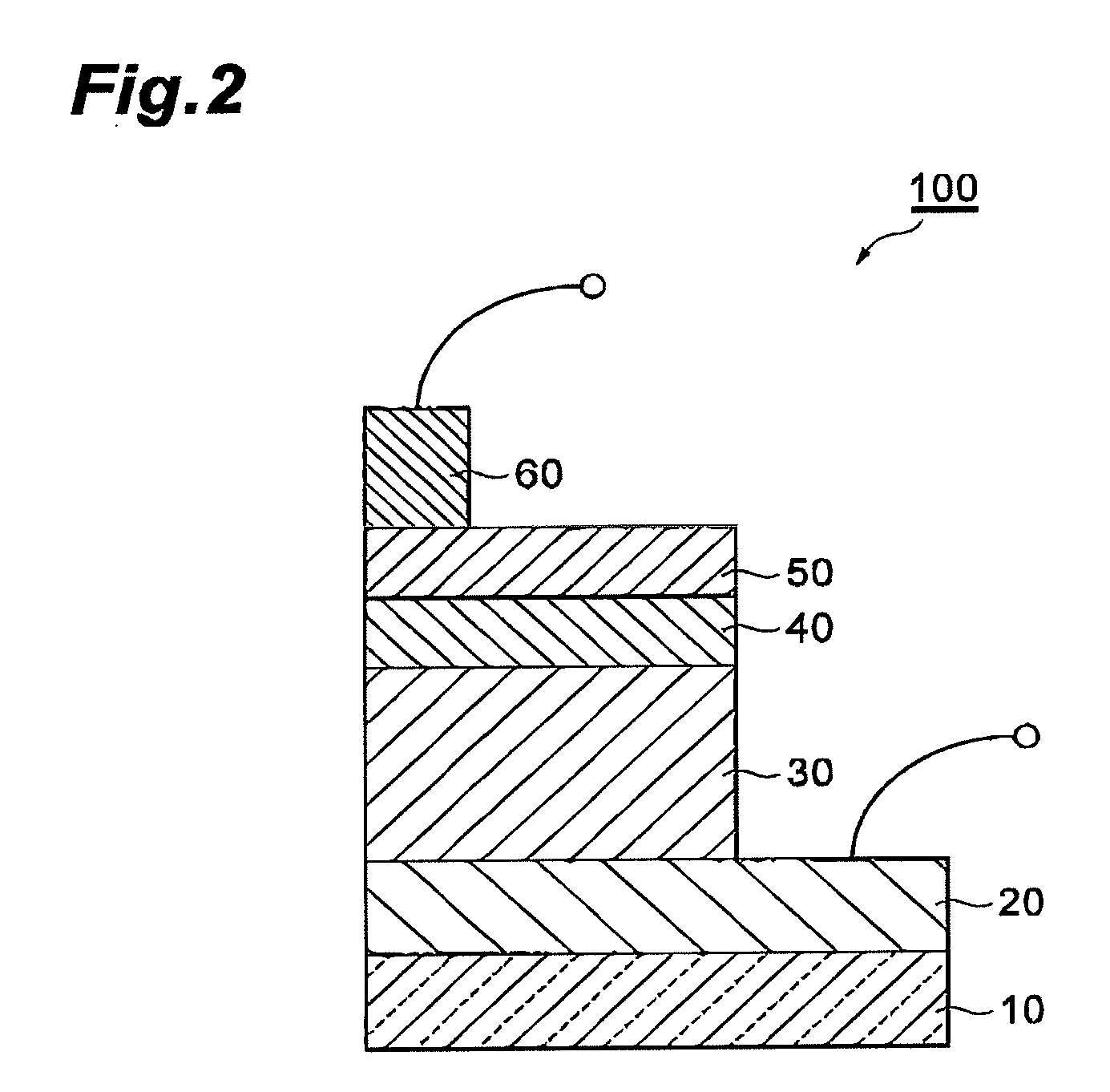

Sintered oxide material, method for manufacturing same, sputtering target, oxide transparent electrically conductive film, method for manufacturing same, and solar cell

ActiveUS20130276879A1Easy dischargeGood light transmissionFinal product manufactureConductive materialIndiumSolar cell

The invention provides an oxide sintered compact 2 composed of a crystal phase which consists of a bixbite-type oxide phase and a perovskite-type oxide phase, or a bixbite-type oxide phase, the crystal phase having indium, tin, strontium and oxygen as the constituent elements, and the indium, the tin and the strontium contents satisfying formulas (1) and (2) in terms of atomic ratio, as well as a sputtering target. There are further provided an oxide transparent conductive film formed using the sputtering target, and a solar cell.Sn / (In+Sn+Sr)=0.01-0.11 (1)Sr / (In+Sn+Sr)=0.0005-0.004 (2)[In formulas (1) and (2), In, Sn and Sr represent indium, tin and strontium contents (atomic percent), respectively.]

Owner:TOSOH CORP

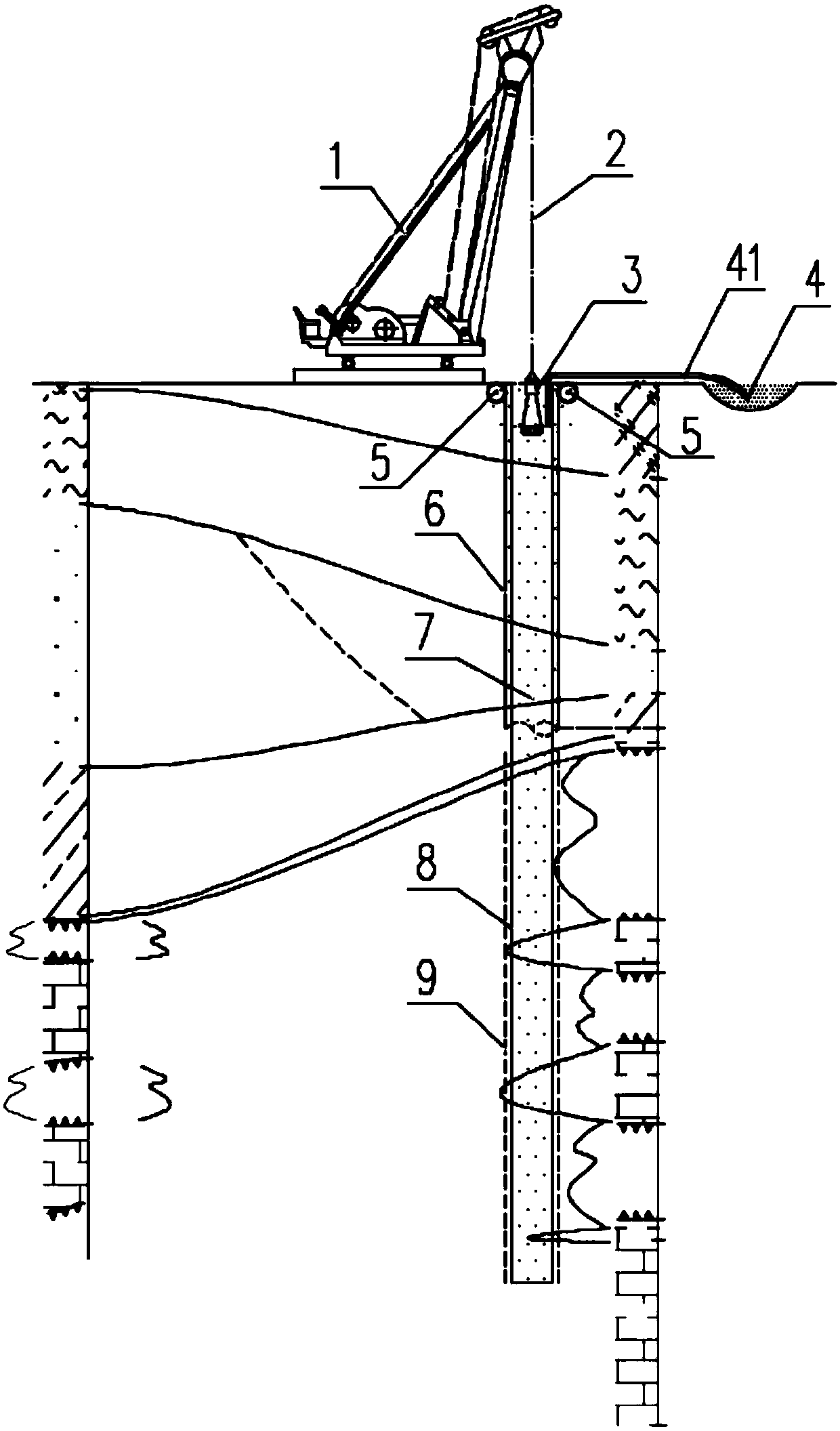

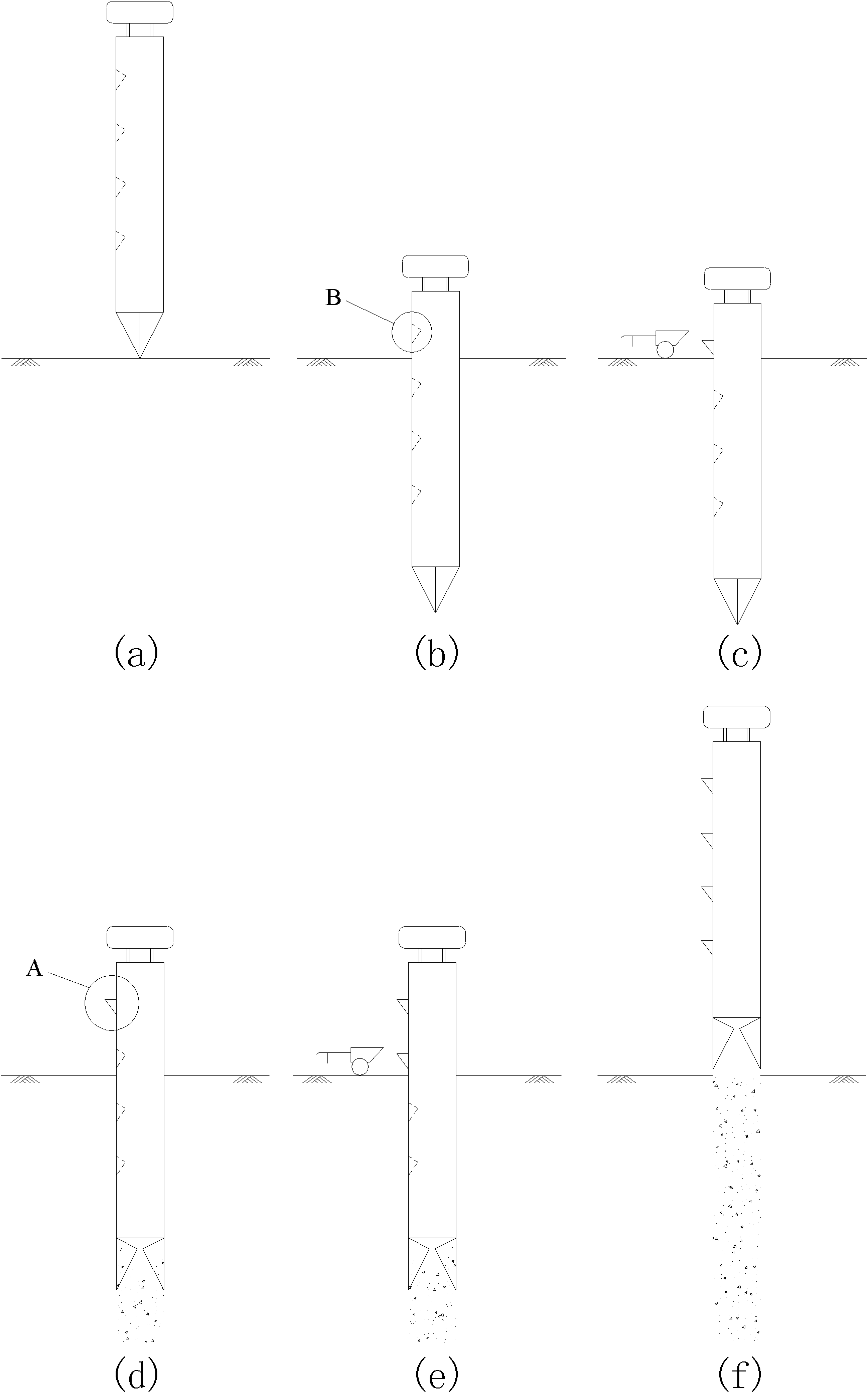

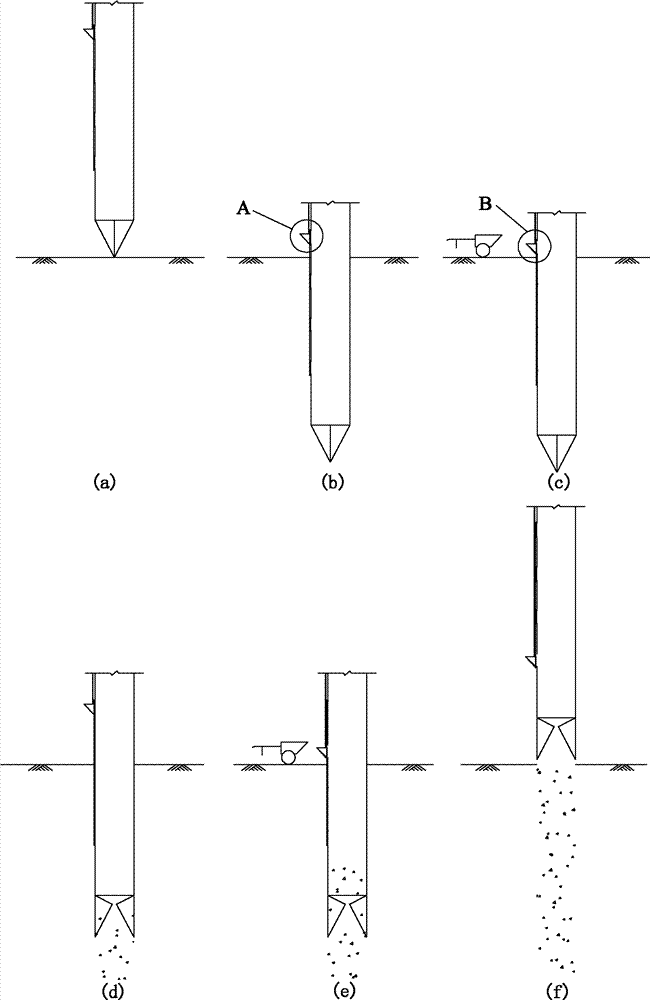

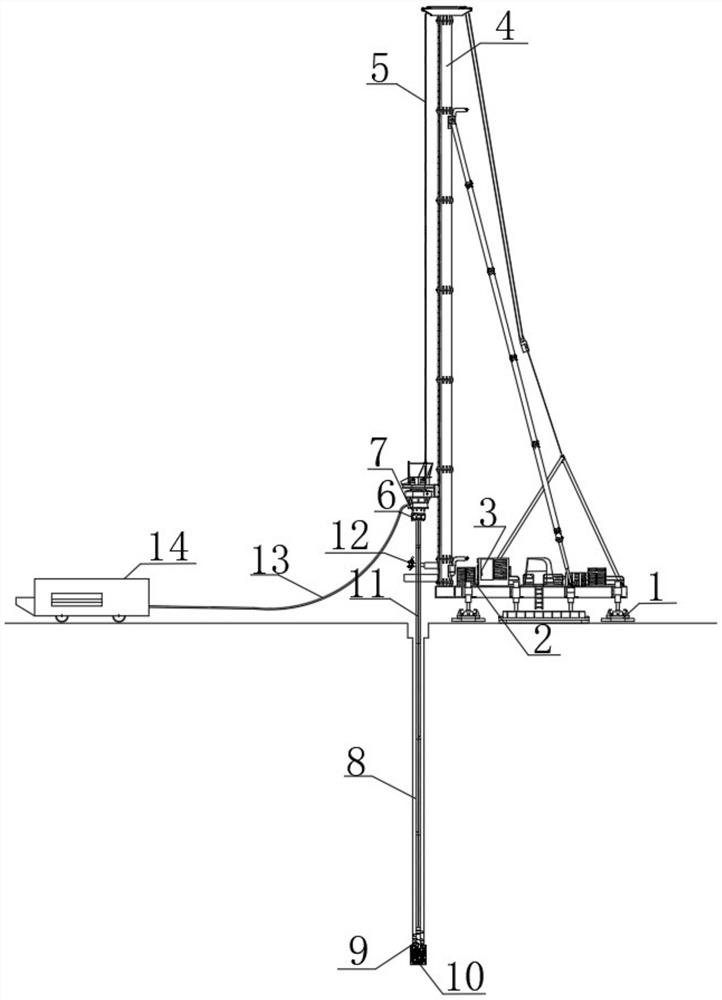

Complex karst site anti-collapse impact holing construction method

The invention relates to a complex karst site anti-collapse impact holing construction method. The method comprises the following steps that a, a punching drilling machine is mounted, and a slurry pool and a slurry circulation system are prepared; b, a steel casing is driven and reinforced; c, impact holing is conducted through a punch hammer of the punching drilling machine in a short-stroke lowpunching and rapid tamping mode, and wall protection is conducted through the steel casing, a mudstone hole wall and the slurry circulation system; and d, a punched hole is cleaned, a reinforcement cage is descended, and concrete is poured. Through the anti-collapse impact holing construction method, construction is convenient and safe, construction in karst sites with complex geologies can be achieved, and meanwhile, the safety of pile driving machines and operators and the pile-forming quality of pile foundations are ensured.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

Filling device and method for waste air-raid shelter of pile foundation construction site

ActiveCN112323823ASmooth Construction MeasuresGuaranteed cycleEmbankmentsFoam concreteArchitectural engineering

The invention provides a filling device and method for a waste air-raid shelter of a pile foundation construction site. The filling method comprises the steps that a grouting drill hole is drilled above a waste air-raid shelter to be filled, a primary grouting pipe, a secondary grouting pipe, an air supply pipe and an air exhaust pipe are installed in the drill hole, the primary grouting pipe andthe air supply pipe vertically extend into the bottom of the air-raid shelter, the secondary grouting pipe and the air exhaust pipe vertically extend to the top of the air-raid shelter, firstly, the primary grouting pipe is connected with a grouting pump, the air supply pipe is connected with an air compressor, foam concrete grouting slurry is injected in a layered mode, the primary grouting pipeand the air supply pipe are pulled up all the way to the top of the air-raid shelter after grouting of each layer is completed, then the secondary grouting pipe is connected to inject the foam concrete grouting slurry for the second time, and air is not supplied during secondary grouting. The filling problem of the deep-buried air-raid shelter can be solved under the condition that excavation is not conducted, normal construction of a cast-in-situ bored pile can be guaranteed on a filled construction site, and the problems that when a rotary drilling rig constructs a cast-in-situ pile foundation, normal construction cannot be conducted on the deep-buried air-raid shelter, the site collapses and the like are solved.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

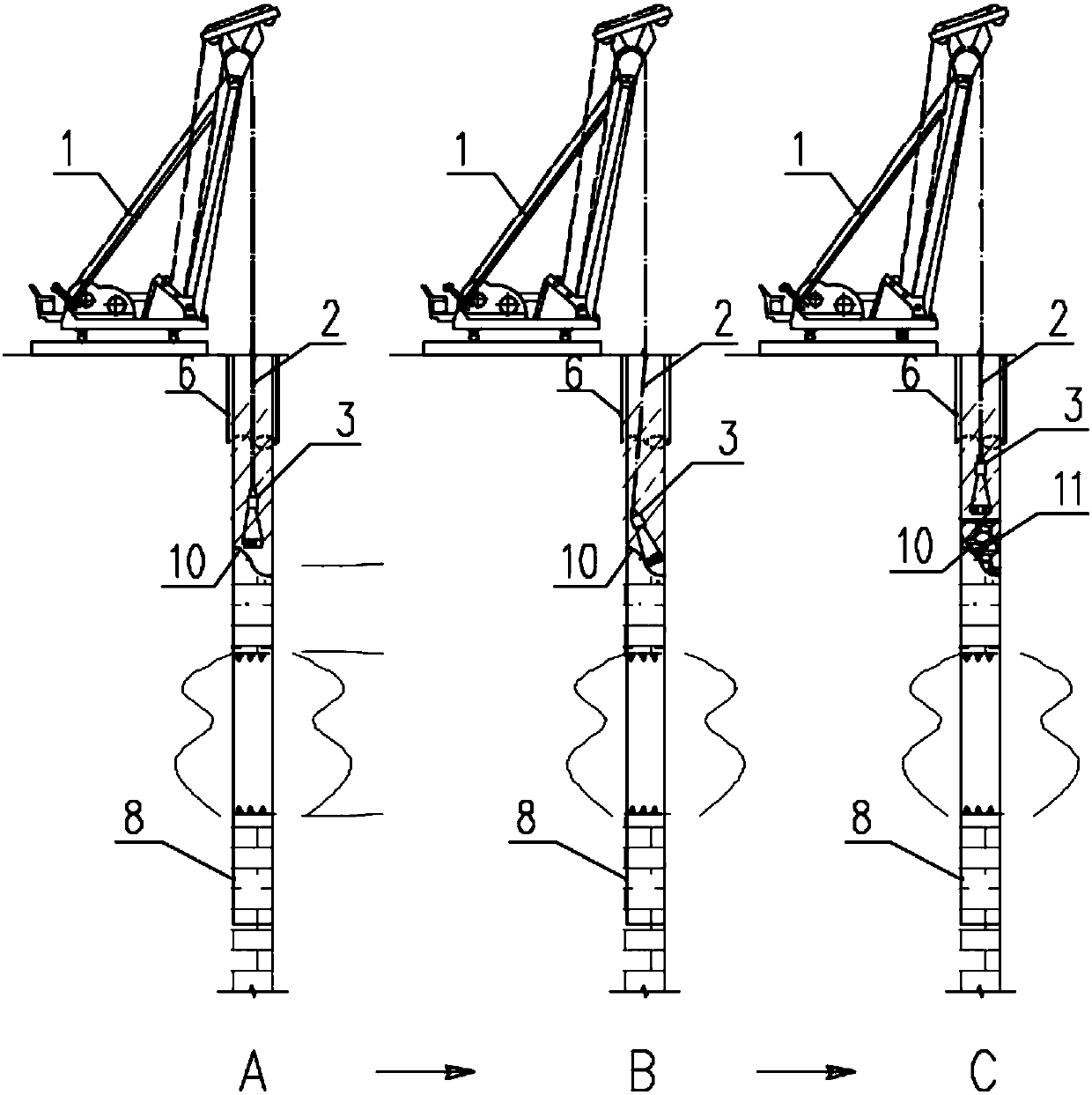

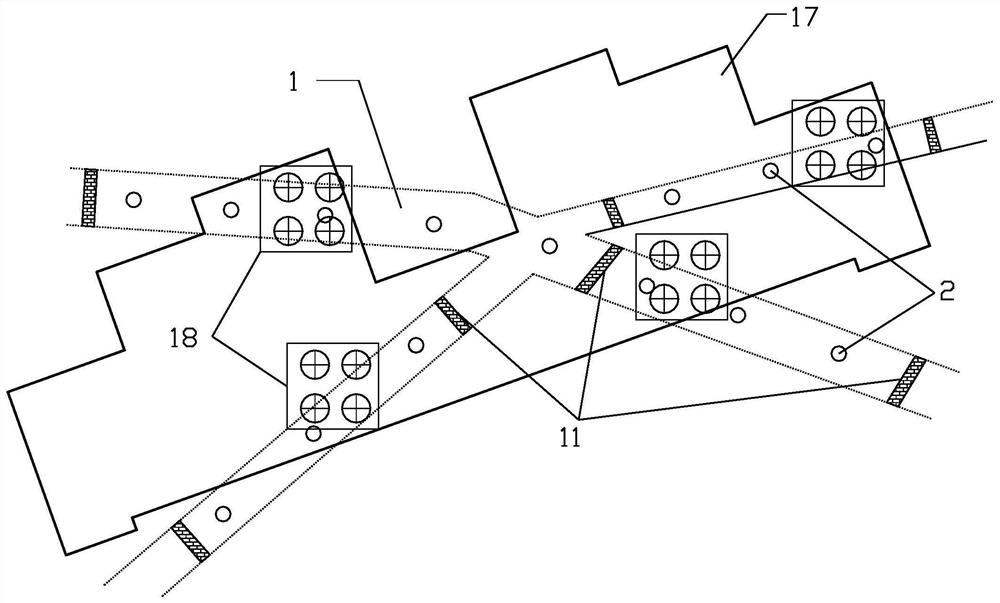

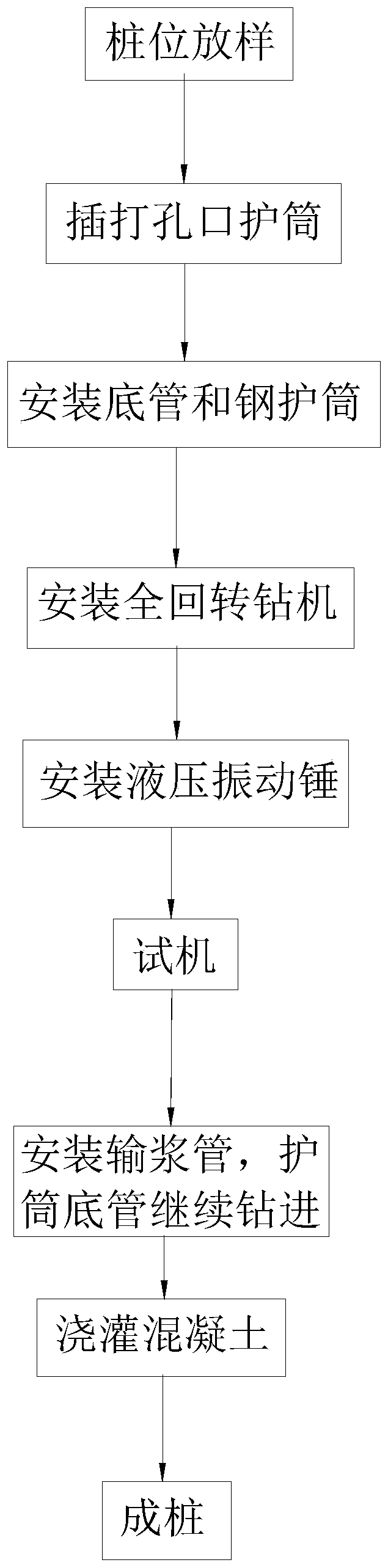

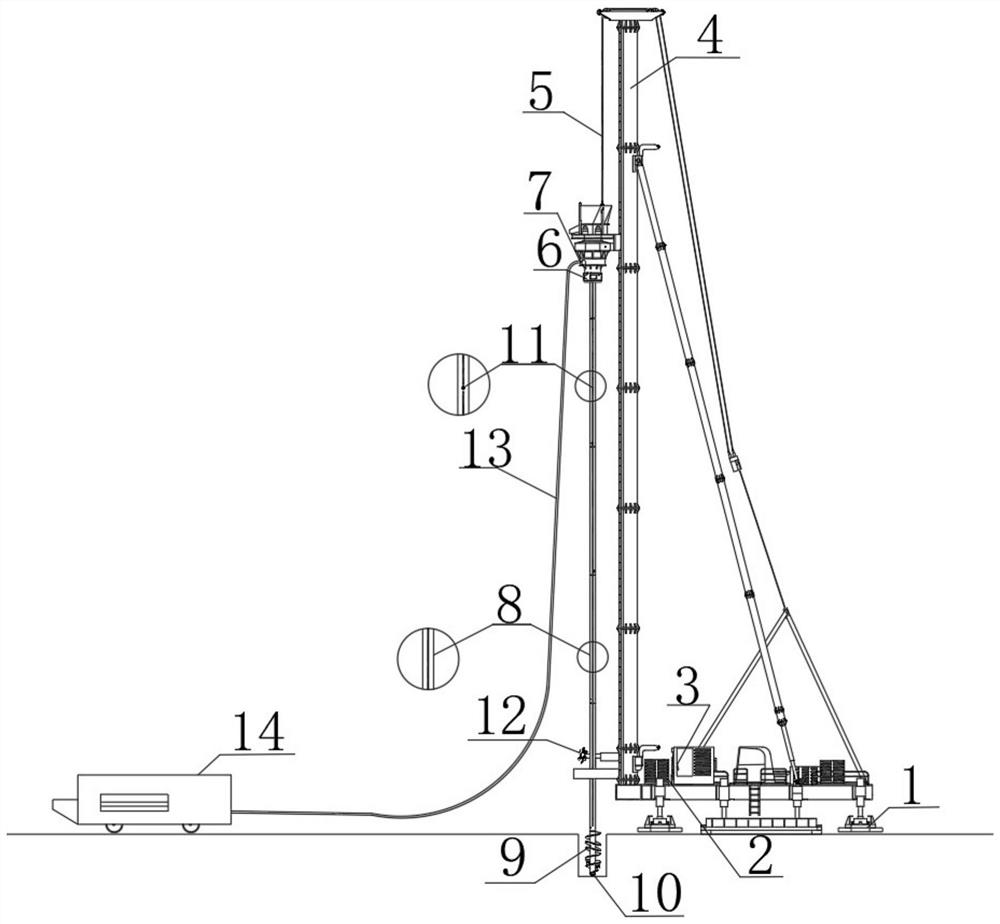

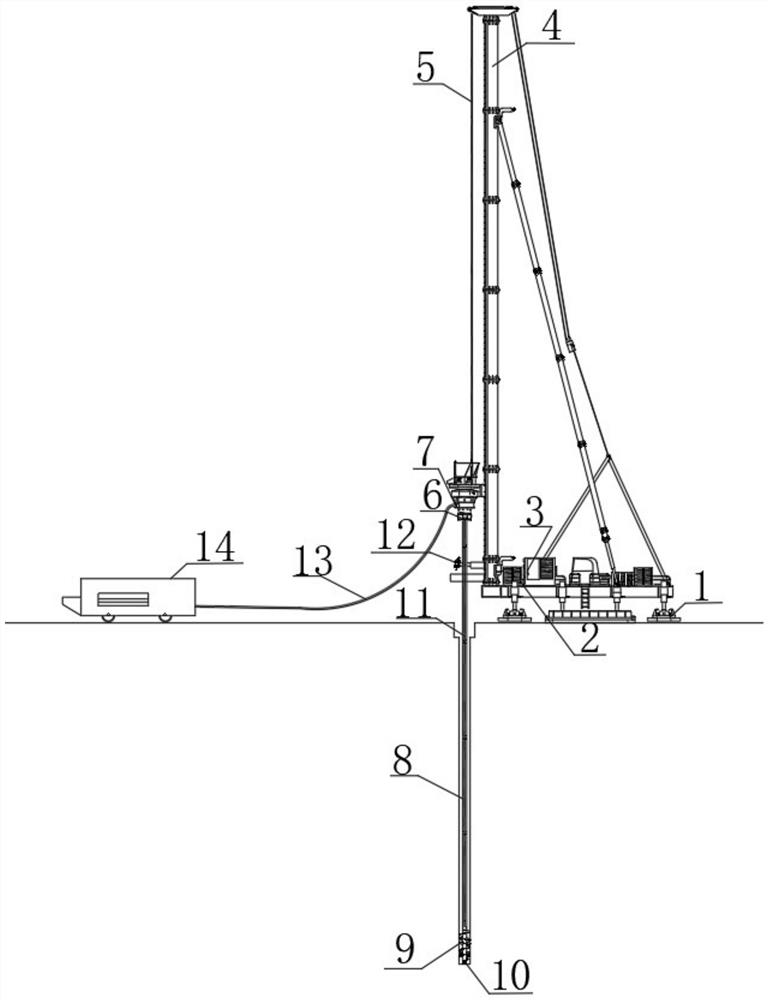

Full-rotating drill and hydraulic vibration hammer synergetic shaft sinking method

The invention relates to the technical field of building foundation engineering construction, in particular to a full-rotating drill and hydraulic vibration hammer synergetic shaft sinking method. Thefull-rotating drill and hydraulic vibration hammer synergetic shaft sinking method comprises the following steps: 1, pile position setting out is conducted; 2, a orifice casing is inserted and struck; 3, a casing bottom pipe and a steel casing are mounted; 4, a full-rotating drill is mounted; 5, a hydraulic vibration hammer is mounted; 6, test-run of a machine is conducted; 7, a mortar conveyingpipe 90 is mounted, and the casing bottom pipe continues being drilled; and 8, concrete is poured, specifically, when drilling is conducted to a preset depth, hole cleaning and acceptance check are conducted, then a reinforcement cage is lowered in to a hole, then the concrete is poured, and the steel casing is pulled out from the hole, and a pile is formed. According to the full-rotating drill and hydraulic vibration hammer synergetic shaft sinking method, drilling into a very complex formation can be conducted, the drilling speed can be increased by four times or above, during hole drilling,because of advanced support of the steel casing, the situation of landslide of a hole wall or orificeis avoided, thus the pouring amount of the concrete can be decreased to the minimum, that is, thefilling coefficient is the minimum, and thus the material cost is saved.

Owner:SHENZHEN SOFORE GEOTECHNICAL ENG CO LTD

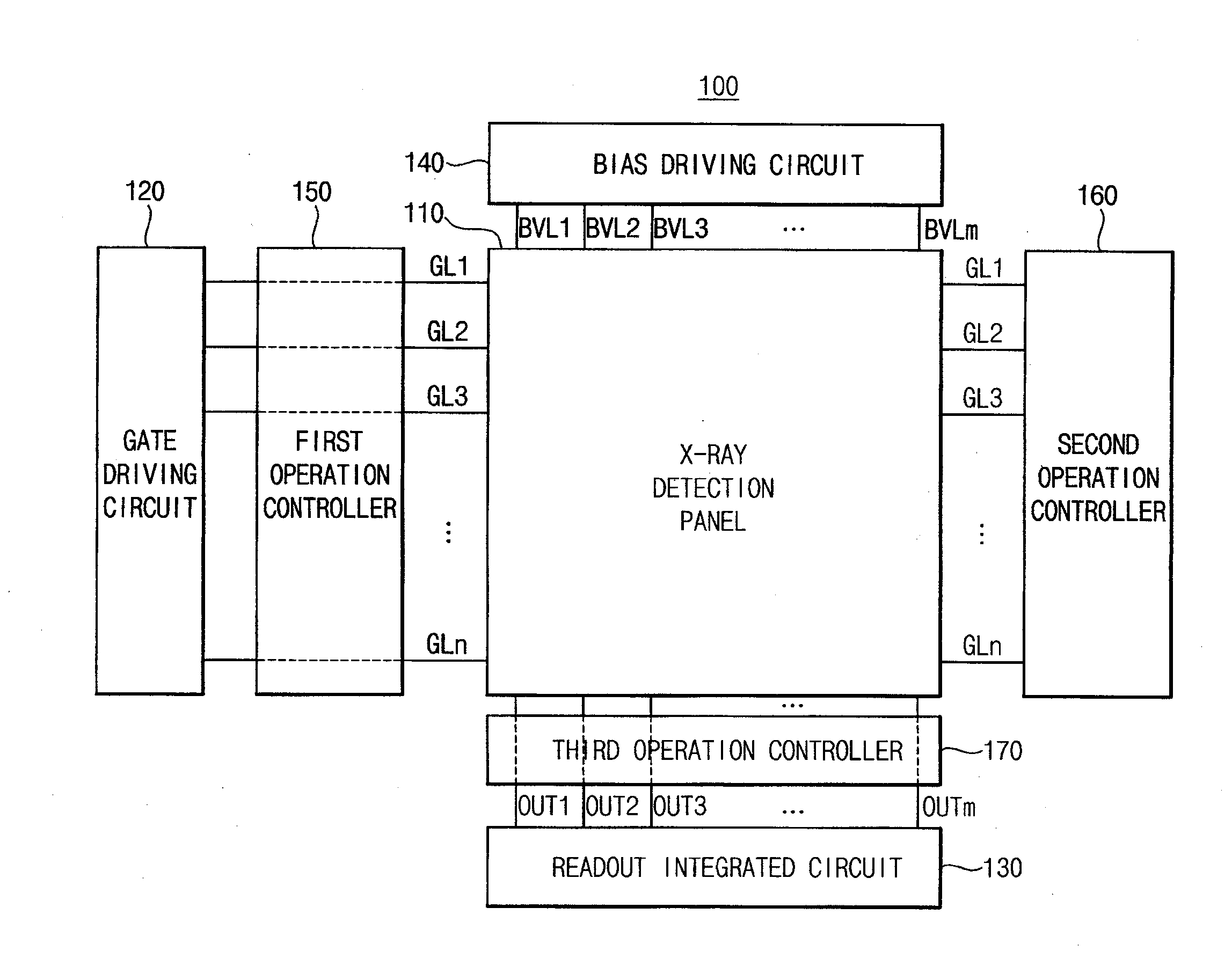

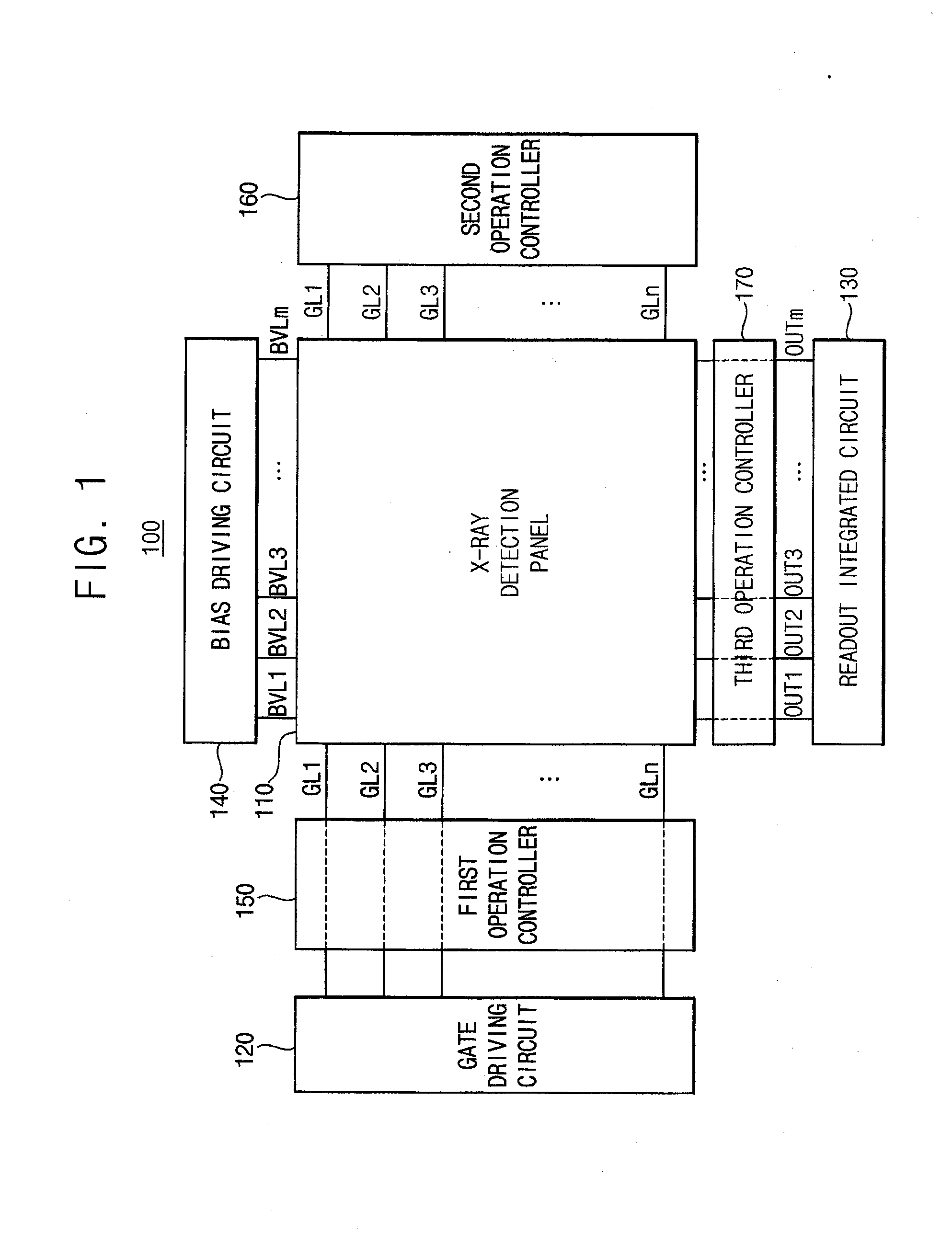

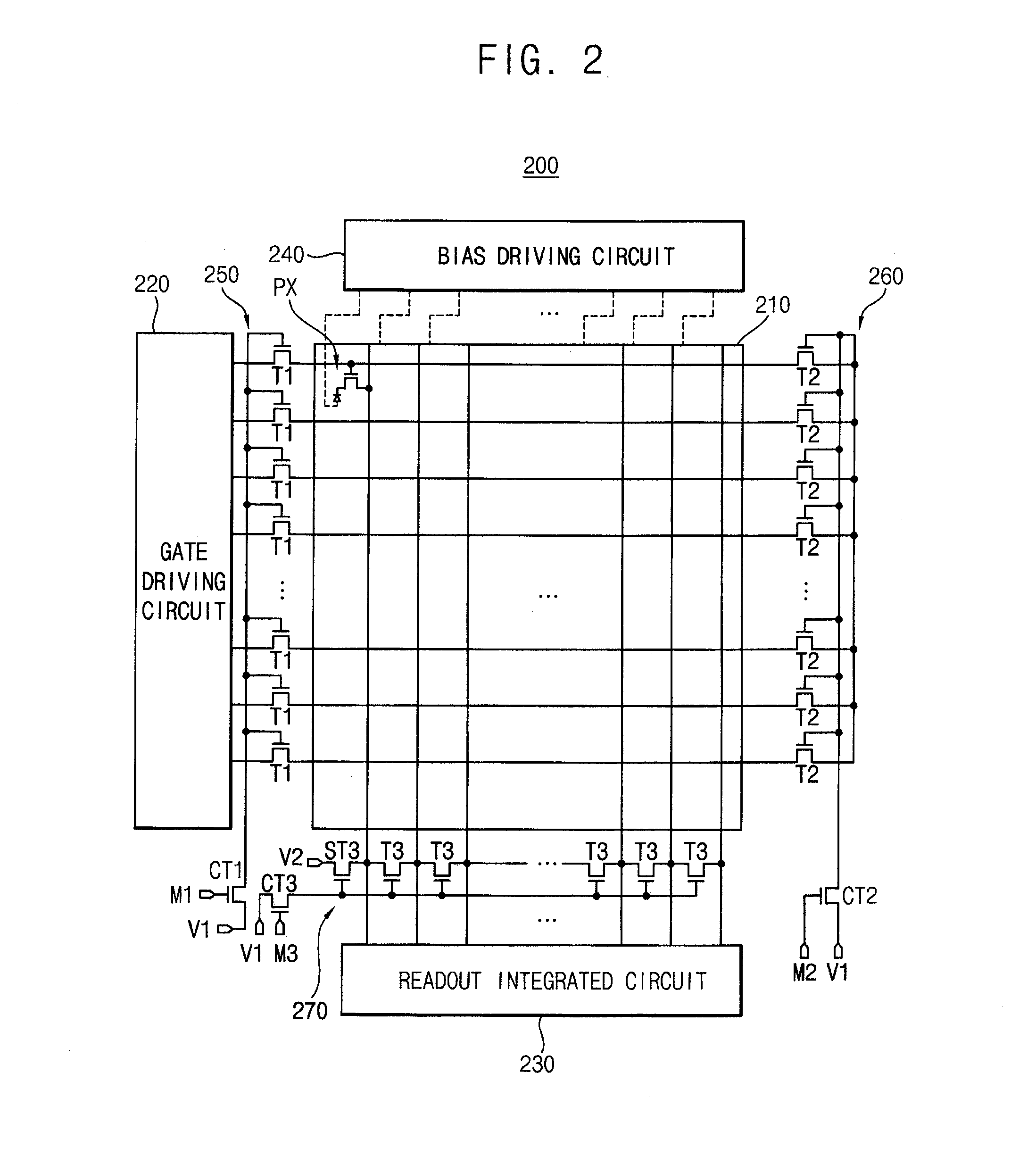

X-ray detection device and method of driving an x-ray detection panel

ActiveUS20140124675A1Reduce image lagLower frame rateTelevision system detailsSolid-state devicesSoft x rayX-ray

An X-ray detection device includes an X-ray detection panel having a plurality of gate-lines, a plurality of data-lines, a plurality of bias-lines, a plurality of pixel circuits, a gate driving circuit that sequentially provides a gate signal to the pixel circuits via the gate-lines when an X-ray detecting operation is performed, a readout integrated circuit that performs a readout operation of a detection signal that is output from the pixel circuits via the data-lines when the X-ray detecting operation is performed, a bias driving circuit that provides a forward-bias voltage or a reverse-bias voltage to the pixel circuits via the bias-lines, and an operation control circuit that controls a forward-biasing operation and an initializing operation to be simultaneously performed on the pixel circuits.

Owner:SAMSUNG DISPLAY CO LTD

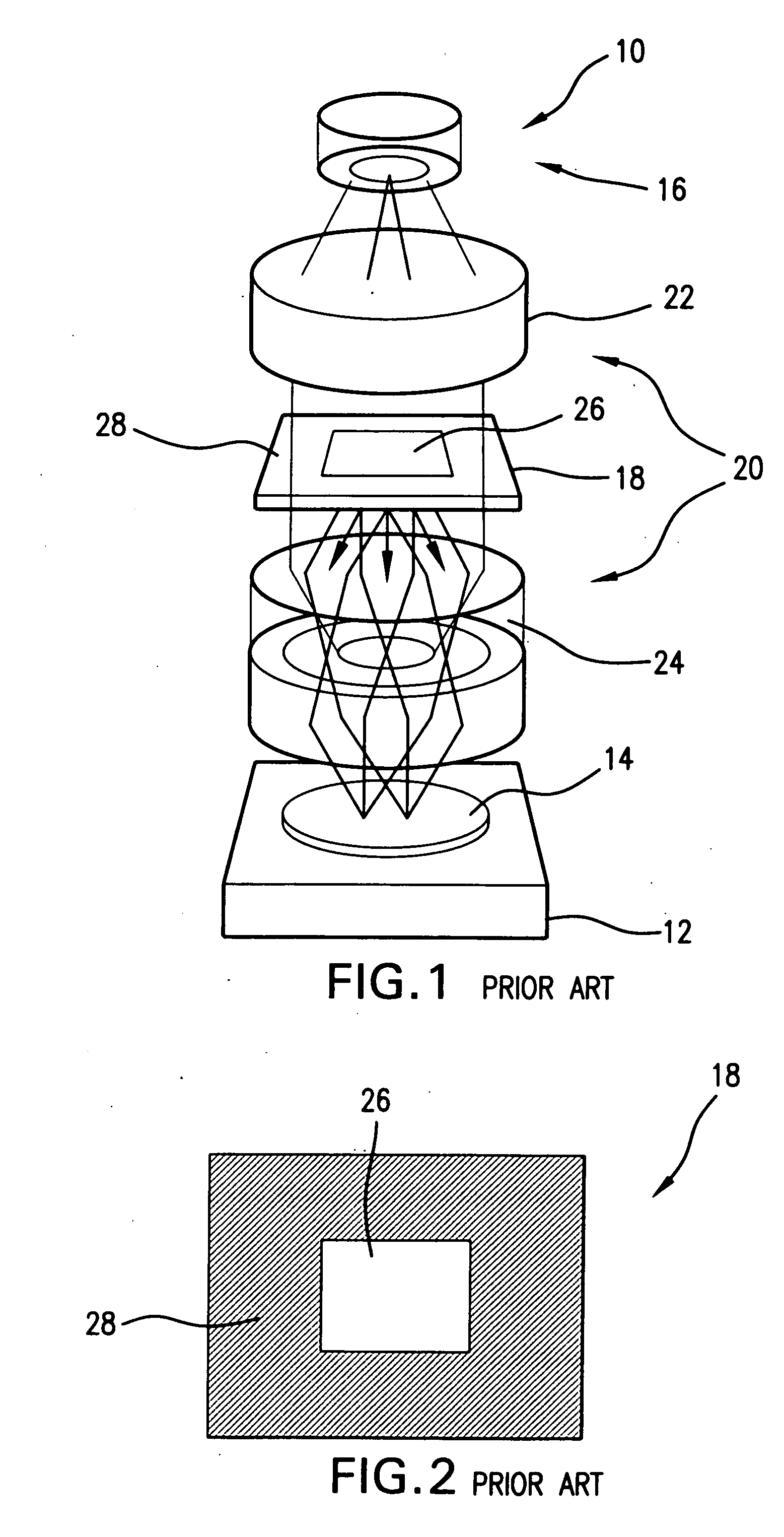

Photolithographic mask exhibiting enhanced light transmission due to utilizing sub-wavelength aperture arrays for imaging patterns in nano-lithography

ActiveUS20090068570A1High light transmittanceShorten write timePhotomechanical apparatusAuxillary shaping apparatusResistNanolithography

A nanophotolithography mask includes a layer of an electrically conductive optically opaque material deposited on a mask substrate in which regular arrays of sub-wavelength apertures are formed. The plasmonic excitation in the layer perforated with the sub-wavelength apertures arrays under the light incident on the mask produces high resolution far-field radiation patterns of sufficient intensity to expose a photoresist on a wafer when propagated to the same. The fill-factor of the mask, i.e., the ratio of the total apertures area to the total mask area, may lead to a significant increase in mask manufacturing throughput by FIB or electron beam “writing”. The mask demonstrates the defect resiliency and ability to imprint coherent clear features of nano dimensions and shapes on the wafers for integrated circuits design.

Owner:UNIV OF MARYLAND

Rotary drilling hole forming method by using multi-stage alloy pilot roller bit in complex stratum cast-in-place pile construction

ActiveCN102409978AEasy to processEasy landing and drillingDirectional drillingLow speedSoil mechanics

The invention discloses a strong karst area cast-in-place pile construction method based on a rotary drilling hole forming manner. The cast-in-place pile construction method is characterized by comprising the steps of: (1) drilling into the surfaces of a karst layer and a gravel soil layer by adopting a conventional bit; (2) in combination with the basic theory of rock-soil mechanics, finding out a mathematic relation between an optimized value of inclination of a multi-stage alloy pilot roller bit and a coefficient of sliding friction between a rock-soil material and the interface of the bit; (3) after adopting the conventional bit to dill into the surfaces of the karst layer and the gravel soil layer, changing the conventional bit into the multi-stage alloy pilot roller bit, firstly drilling at high pressure and low speed, and then, after the bit is dilled into the rock for more than 50 cm, drilling at low pressure and high speed until the drilling depth or hole depth satisfies design requirements; (4) optimizing the design of mud specific weight in stages for preventing pile holes from collapsing and improving the bearing capacity of pile foundations; and (5) handling sudden accidents, such as fracture of drilling rods, bit falling, bit burying, fracture of cone palms in holes, accidental falling of cone palms and other small operation tools and the like, in the drilling process by adopting a drill tool overshot and a falling object salvage skip.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

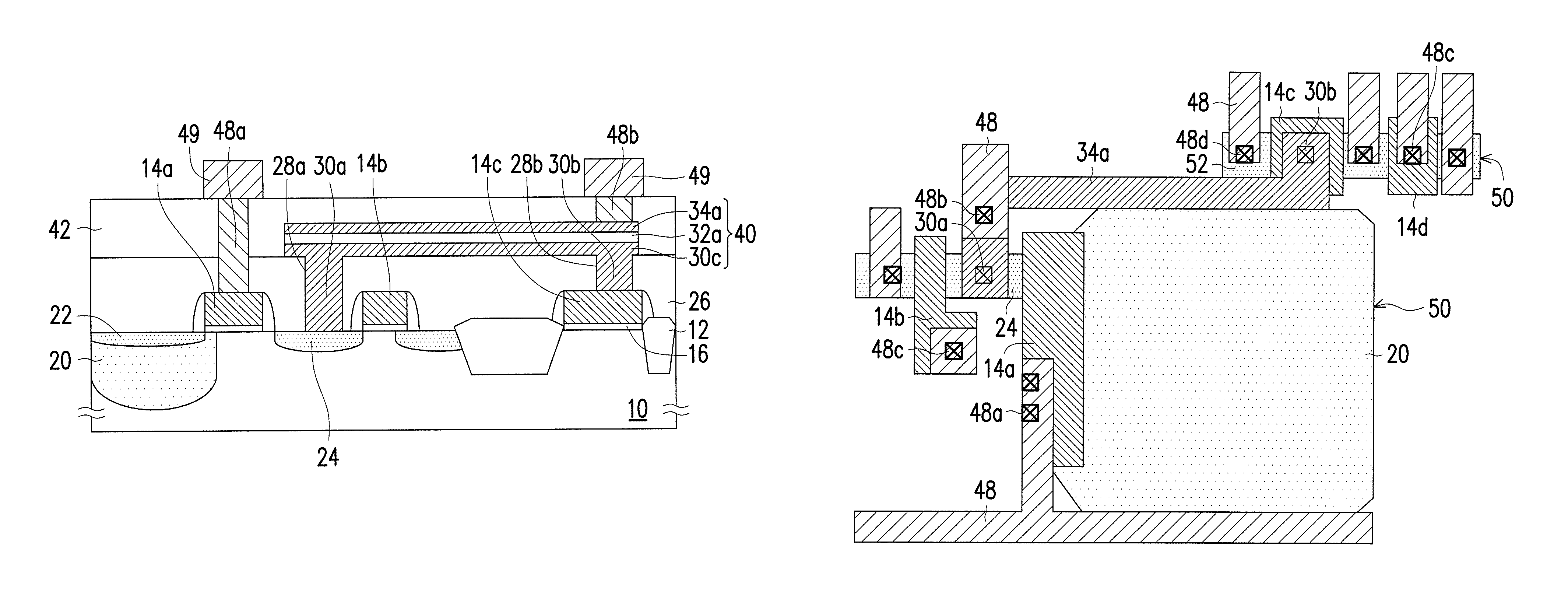

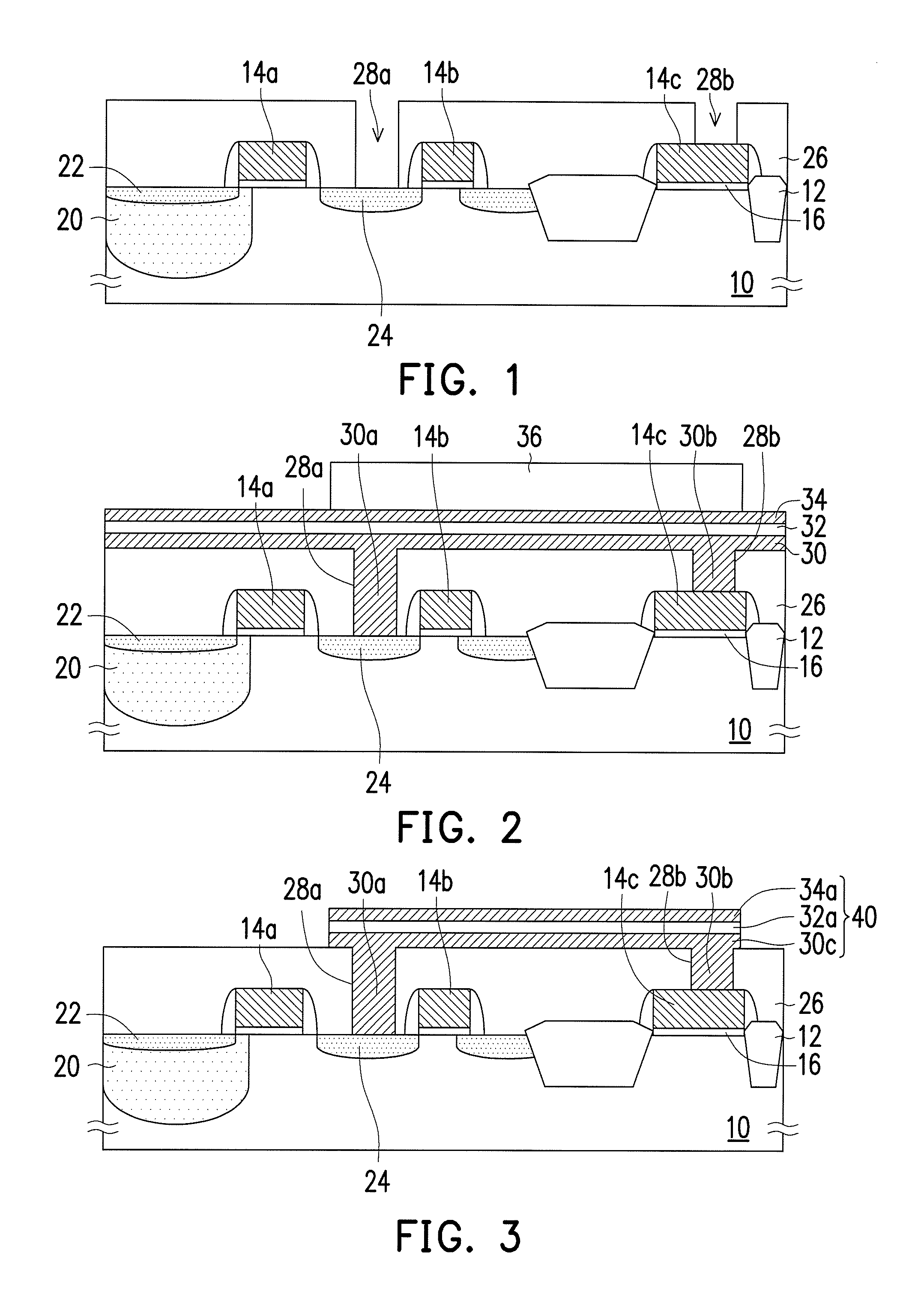

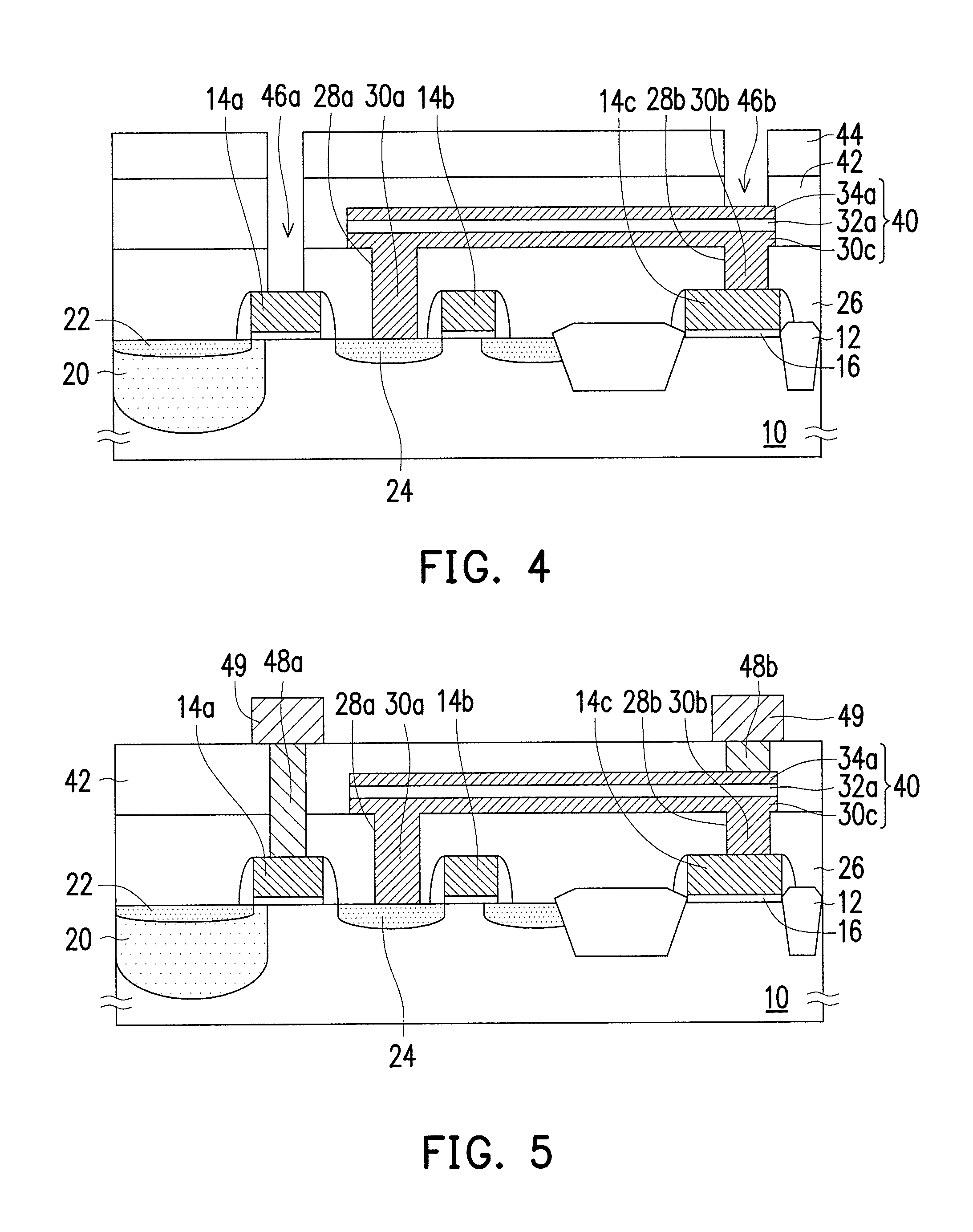

CMOS image sensor unit and method for fabricating the same

ActiveUS9391115B1Improve dynamic rangeTotal current dropTransistorSolid-state devicesCMOSEngineering

A CMOS image sensor unit and a method for fabricating the same are described. The image sensor unit includes a photodiode, a transfer gate, a reset gate, a source follower gate, a floating drain region between the transfer gate and the reset gate, and a PIP capacitor. The lower poly-Si electrode of the PIP capacitor is electrically connected with the floating drain region and the source follower gate to also serve as an interconnect between the floating drain region and the source follower gate. The fabrication method includes forming contact plugs on the floating drain region and the source follower gate, and then forming a PIP capacitor whose lower poly-Si electrode is connected with each contact plug.

Owner:POWERCHIP SEMICON MFG CORP

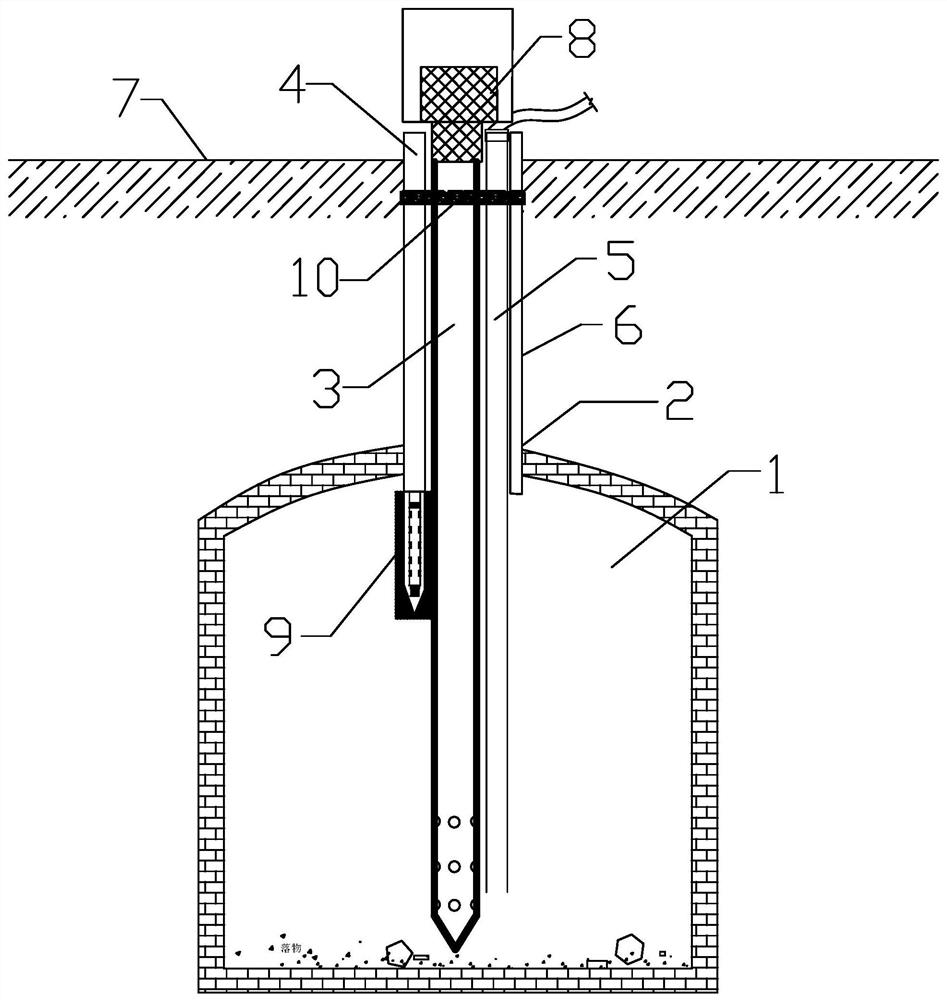

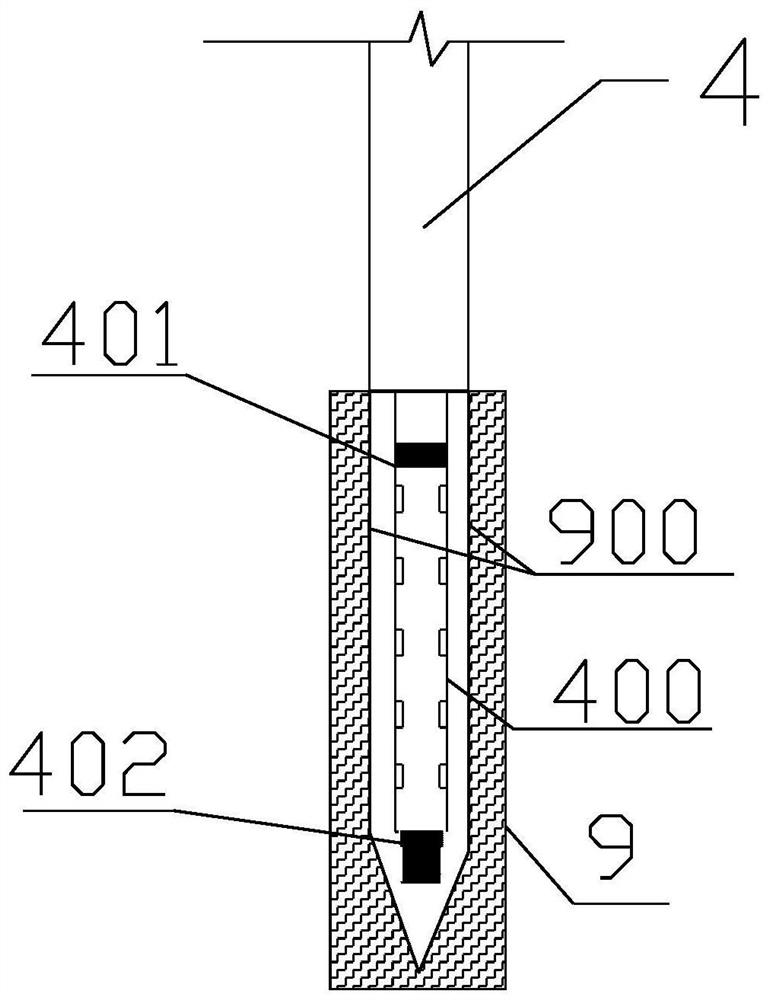

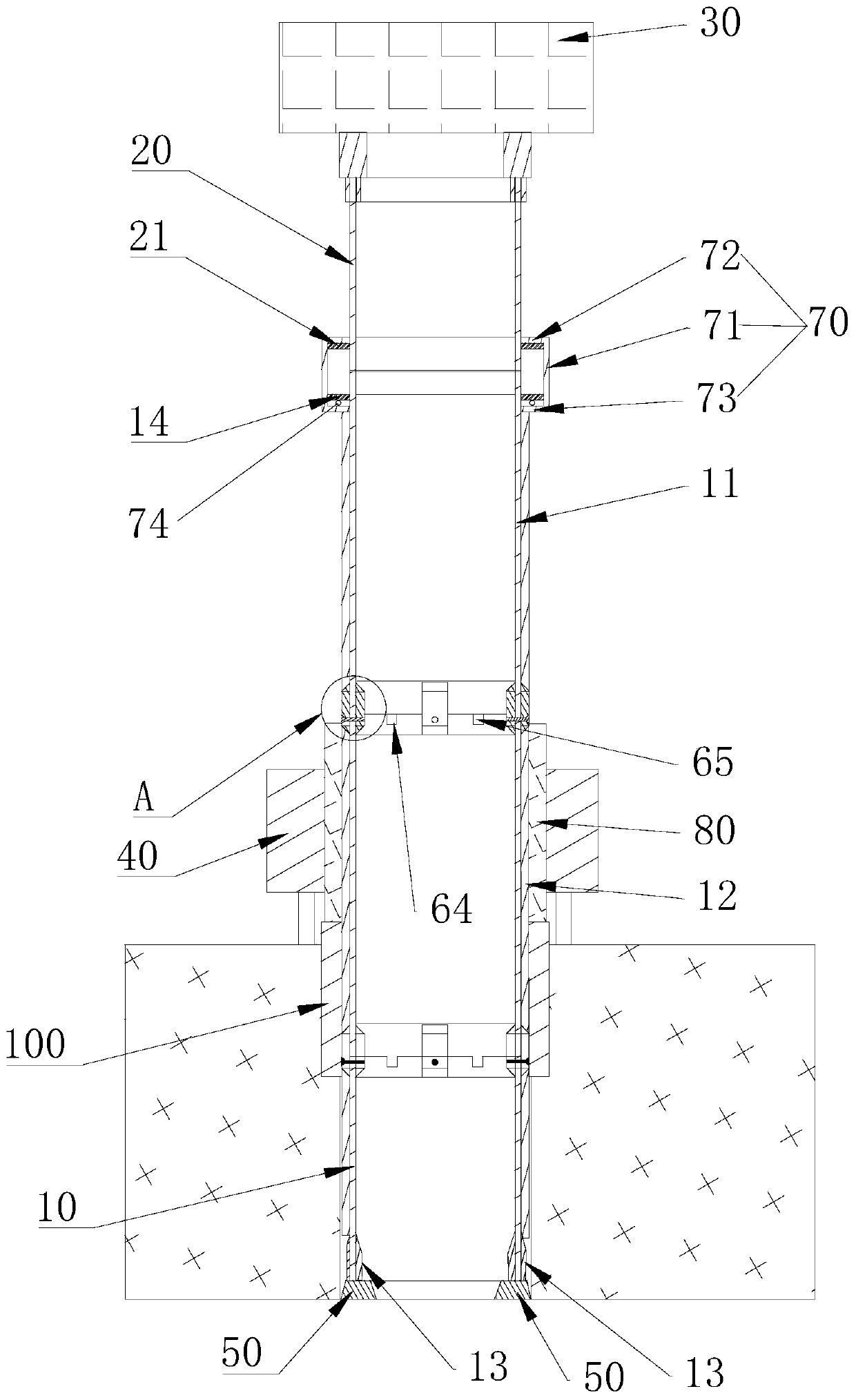

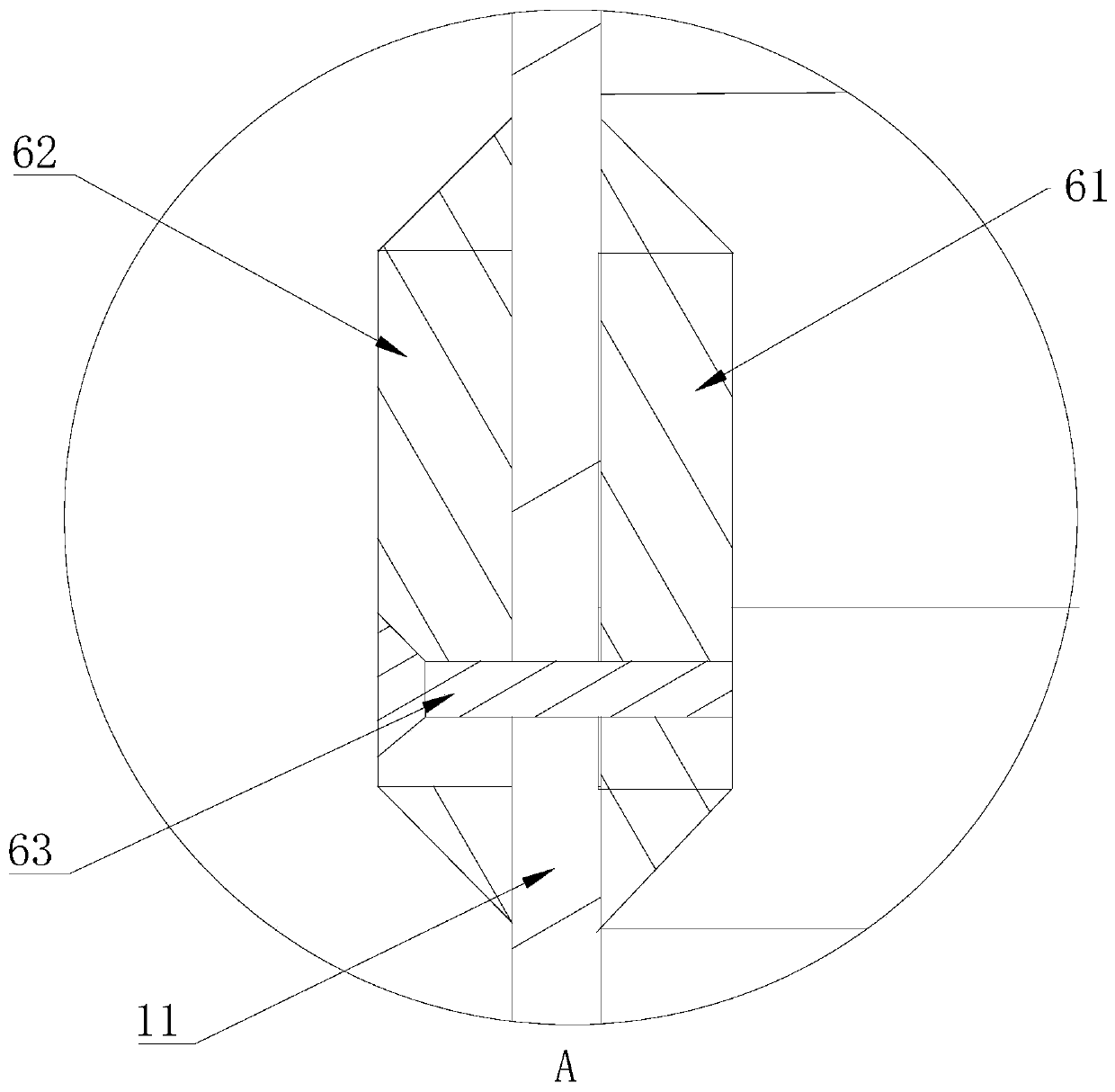

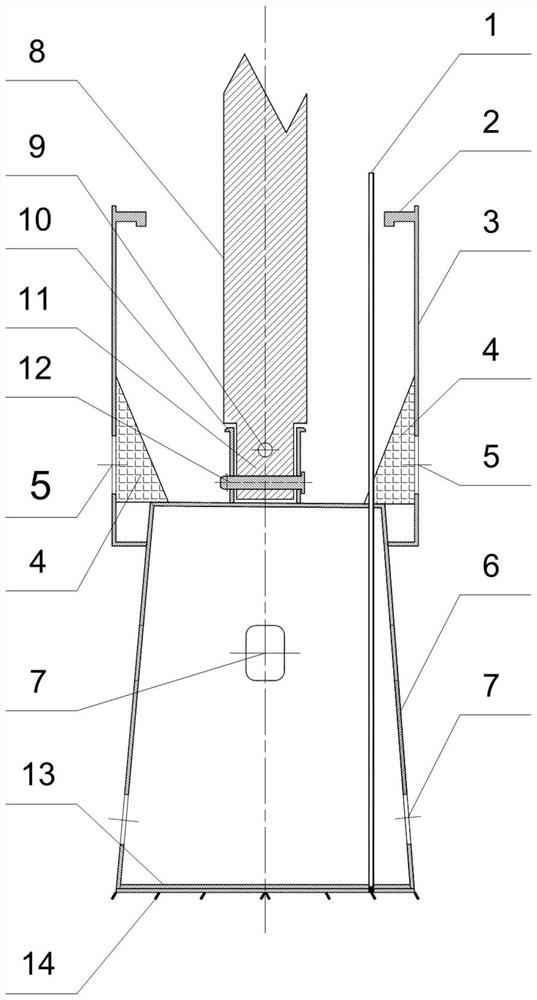

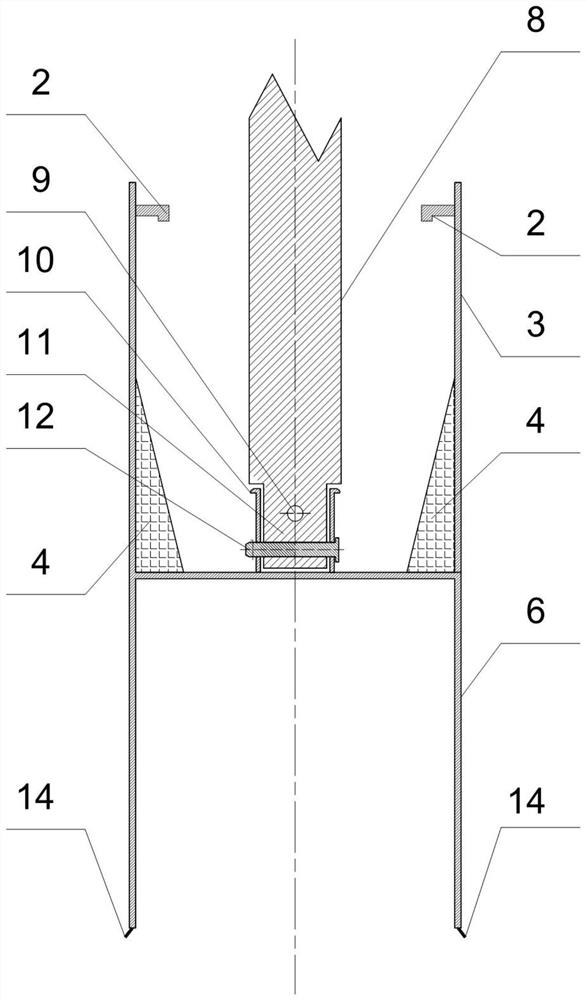

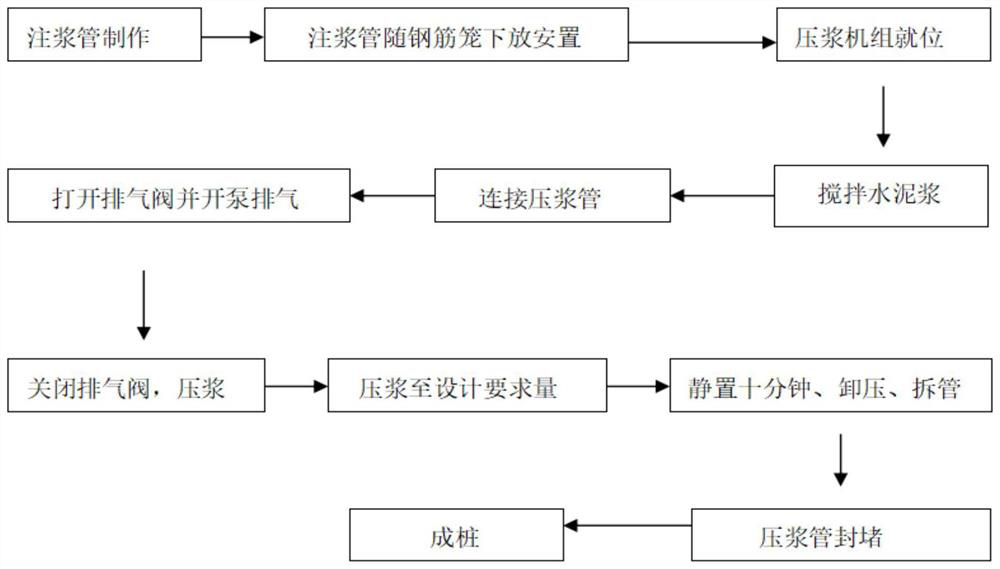

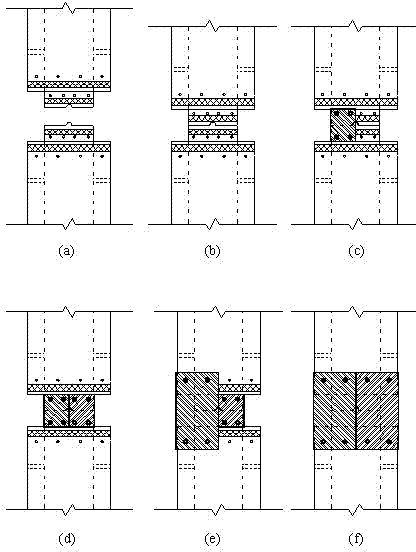

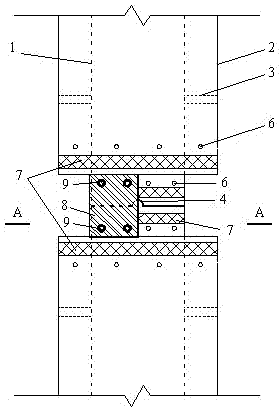

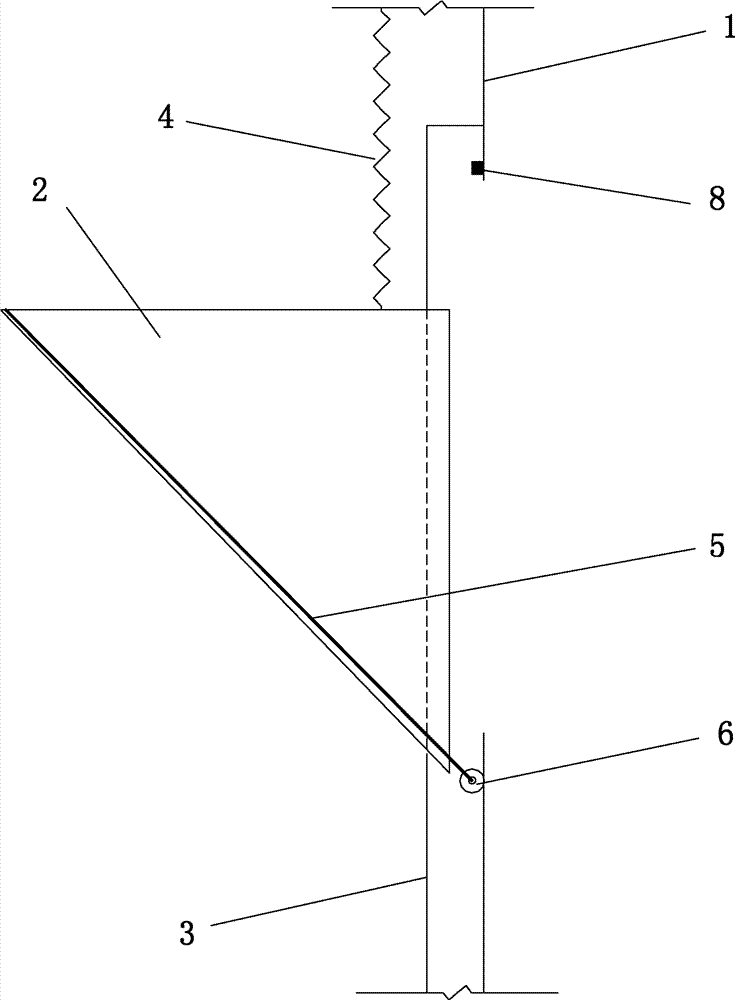

Construction method of cast-in-place pile

ActiveCN110700245ADecrease the filling factorHigh strengthBulkheads/pilesRebarGeotechnical engineering

The invention discloses a construction method of a cast-in-place pile, and aims to solve the technical problem that in the prior art, due to the fact that the filling coefficient of the side wall in apile hole of a cast-in-place pile is large, concrete leaks too much to the side wall in the pile hole, and the strength of the cast-in-place pile is reduced. The construction method comprises the following steps: driving a casing protection barrel underground at the ground position where the cast-in-place pile is designed, and digging out soil and sand in the casing protection barrel; then vibrating and extruding a vibration guide downwards along the casing protection barrel to penetrate into the underground through a hydraulic vibration hammer, and then taking out the vibration guide to supplement soil and compact the soil; and then, placing a reinforcement cage in the pile hole, pouring concrete into the middle of the pile hole and pulling out the casing protection barrel, completely pulling out the casing protection barrel after the pouring of the concrete is finished, and finishing the construction of the cast-in-place pile after the concrete is completely solidified. According tothe construction method, the filling coefficient of the periphery of the side wall in the pile hole can be greatly reduced, excessive outward leakage of concrete in the pile hole is prevented, and the strength of the cast-in-place pile is improved.

Owner:江西思绮建筑工程有限公司

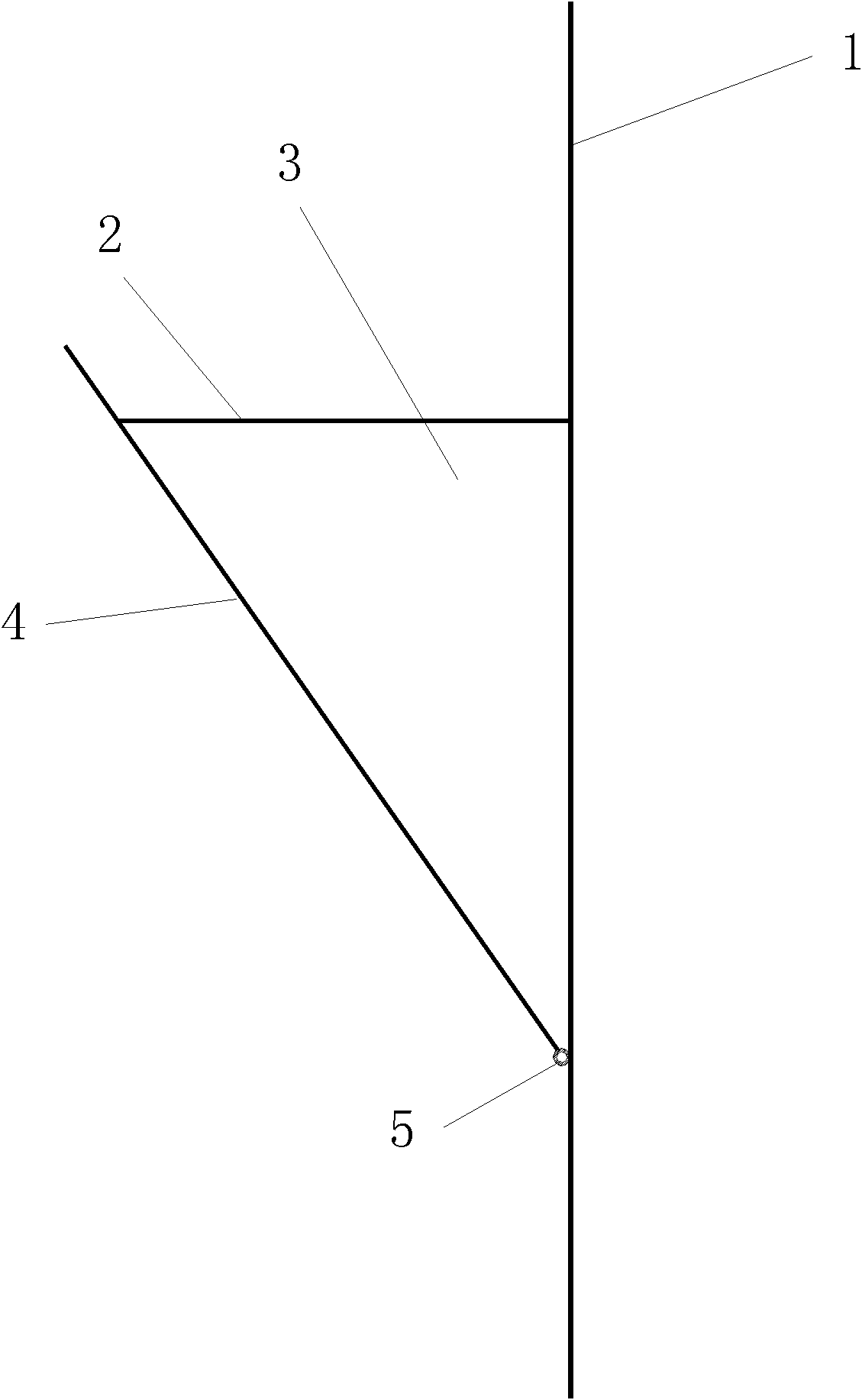

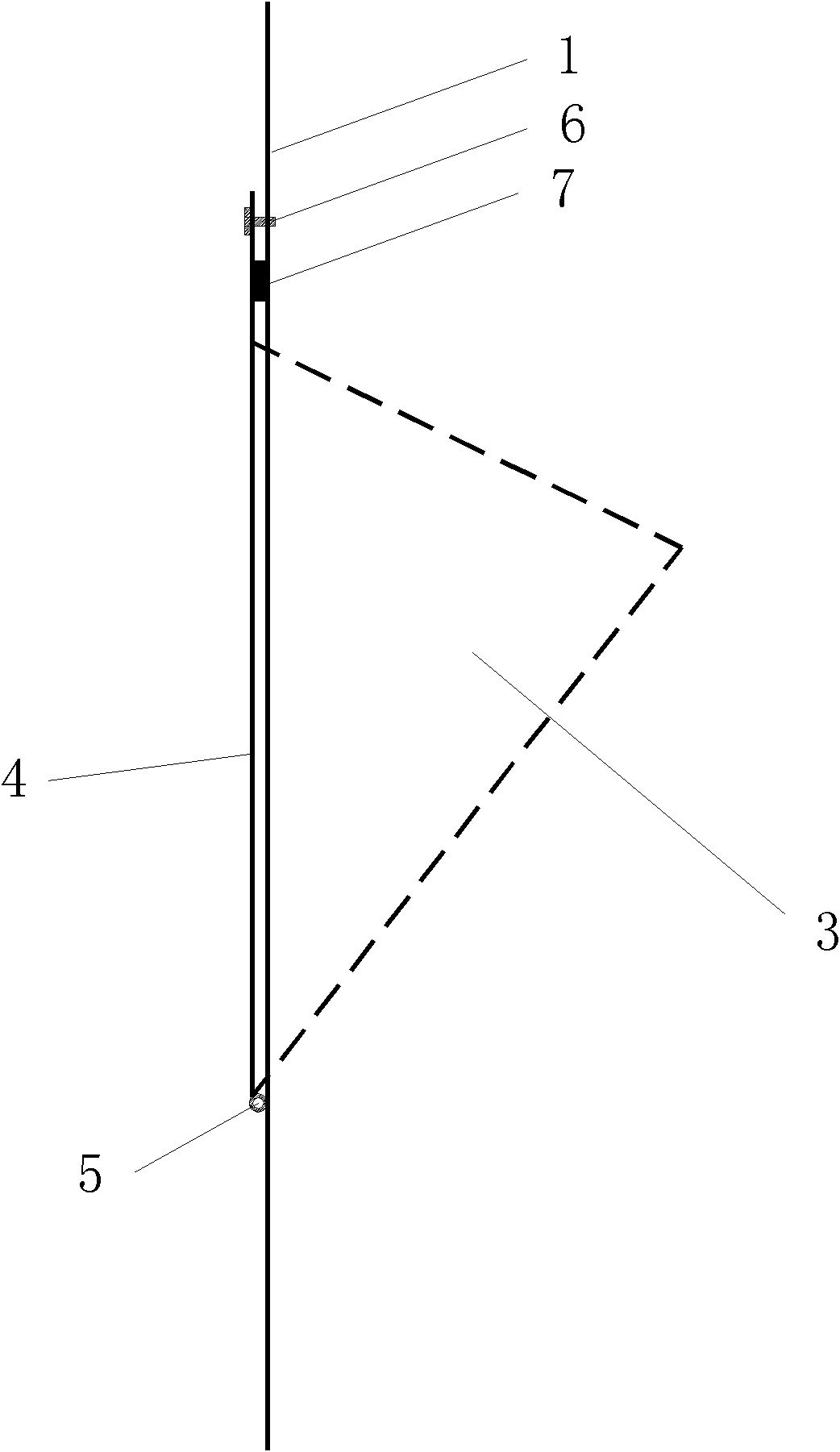

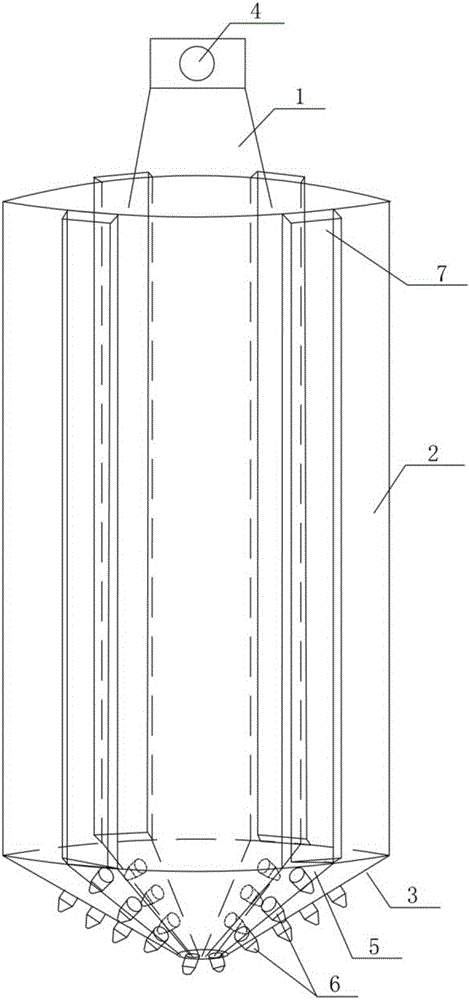

Karst stratum rotary drilling anti-deviation drilling tool and drilling method thereof

ActiveCN111677446AImprove stabilityGuaranteed stiffnessDrill bitsDrilling rodsStructural engineeringMechanical engineering

The invention discloses a karst stratum rotary drilling anti-deviation drilling tool and a drilling method thereof, and relates to the technical field of rotary drilling. The karst stratum rotary drilling anti-deviation drilling tool comprises a verticality keeping barrel, a rotary drilling bit, a connecting pin, a bit fishing plate and a reinforcing assembly, wherein the rotary drilling bit comprises a drilling slag barrel and a bit square sleeve arranged in the middle of the top end of the drilling slag barrel, and the bit square sleeve is provided with a first connecting pin hole; the drillbit square sleeve is used for being connected with a rotary drilling rod through a connecting pin, the verticality keeping barrel is fixed to the upper end of the drilling slag barrel, the verticality keeping barrel and the drilling slag barrel are fixedly connected with the reinforcing assembly, and a working hole is formed in the lower end of the side wall of the verticality-keeping barrel andcorresponds to the first connecting pin hole in position; and the bit fishing plate is arranged at the top of the verticality keeping barrel and is an annular steel plate, and an annular protrusion extending downwards is arranged on the inner edge of the annular steel plate. The karst stratum rotary drilling anti-deviation drilling tool and the drilling method are suitable for being applied to drilling of seriously uneven stratums such as karst development areas or foundation pit supporting and piling construction, and the drilling perpendicularity can be guaranteed.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

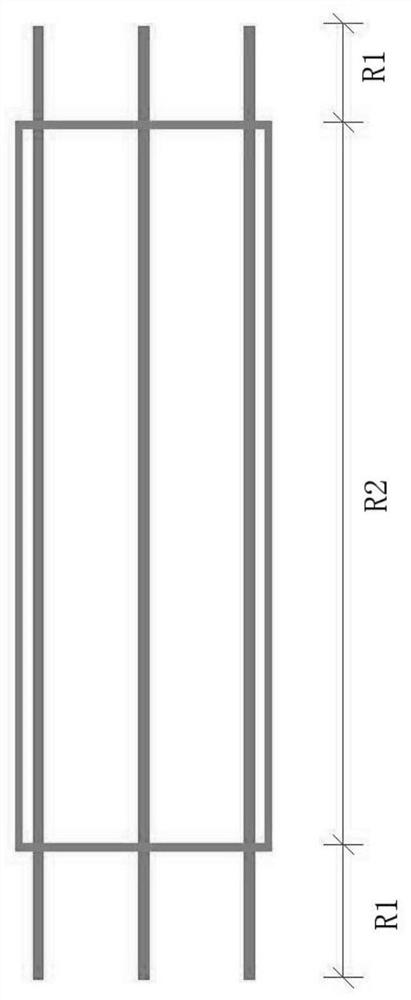

Method for reducing filling coefficient of cast-in-place pile in ultra-deep silt geology

The invention discloses a method for reducing the filling coefficient of a cast-in-place pile in the ultra-deep silt geology. A manufacturing method of the cast-in-place pile comprises the steps that S1, the length of an outer cover of an iron sheet is determined according to the hole forming depth and the construction environment geology; and S2, a reinforcement cage is manufactured, the reinforcement cage comprises a positioning hoop, vertical ribs and spiral ribs from inside to outside, the reinforcement cage is formed by connecting multiple sections of unit cage bodies, all the sections of unit cage bodies are connected through welding, and the welding positions between the unit cage bodies are wrapped with iron sheets after welding is completed. The reinforcement cage of the cast-in-place pile is wrapped with the iron sheet, the flowing range of concrete is limited, the concrete is poured in the range of the reinforcement cage, the concrete poured into the reinforcement cage is prevented from flowing out, the problem that the underwater concrete flows to a sludge collapse area possibly existing during pouring is solved, the situation that the foundation pit foundation construction range is affected due to excessive collapse is avoided, and meanwhile, the hole collapse area is not filled with the concrete, so that the actual use amount of the concrete is reduced, and the filling coefficient is reduced.

Owner:CHINA 19TH METALLURGICAL CORP

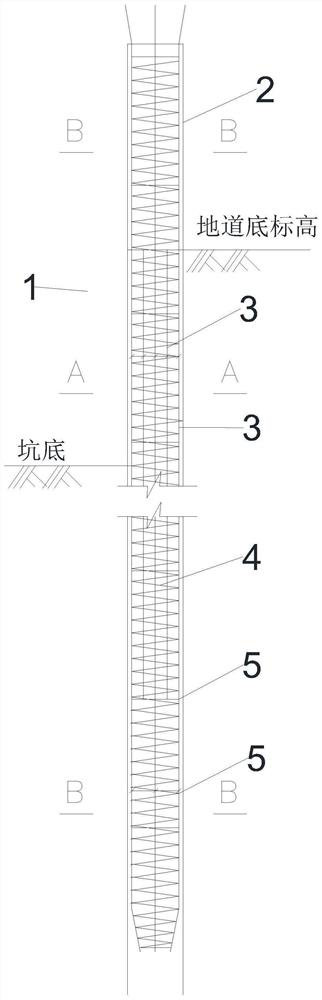

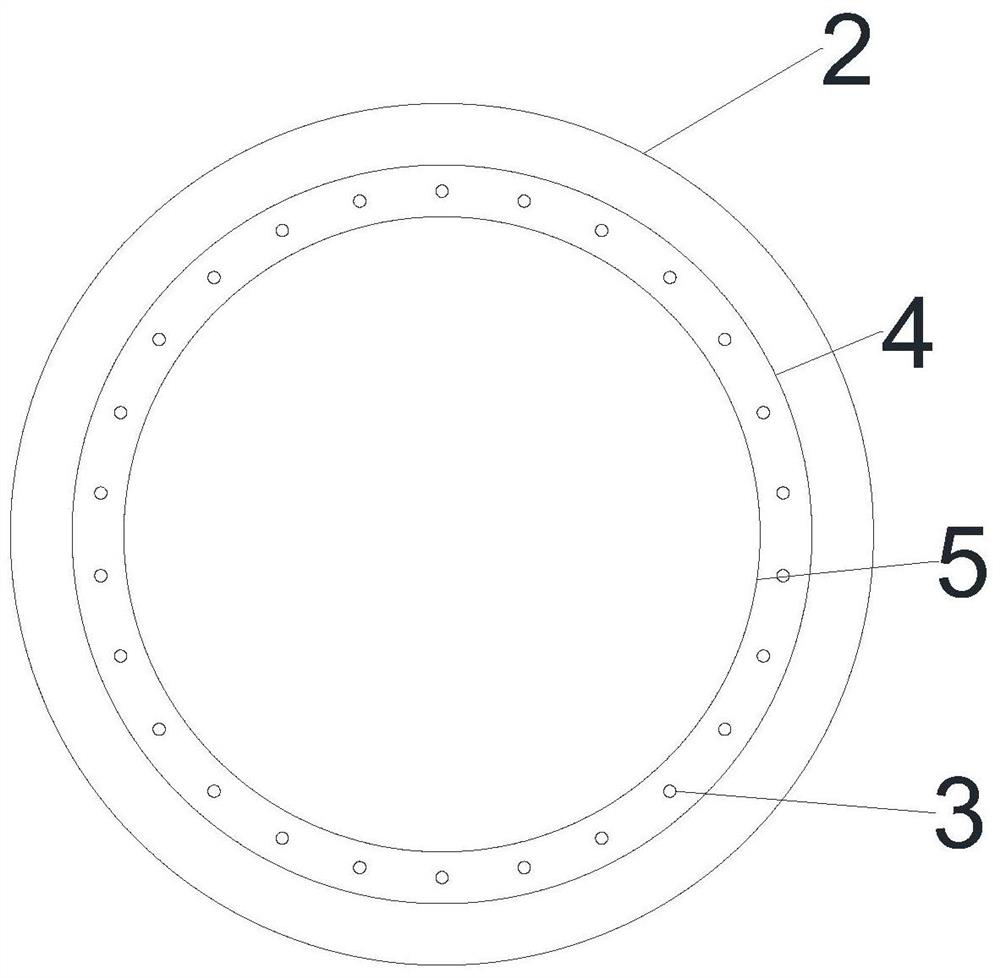

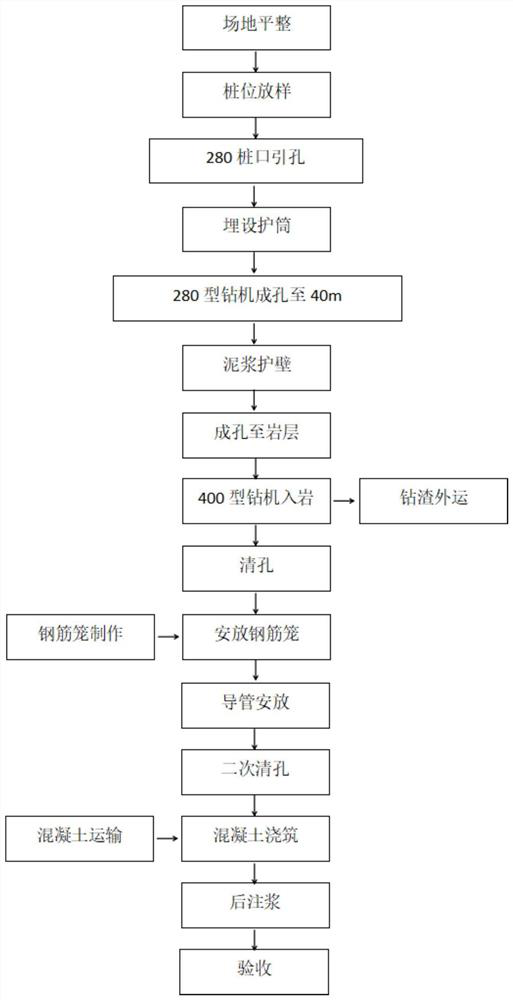

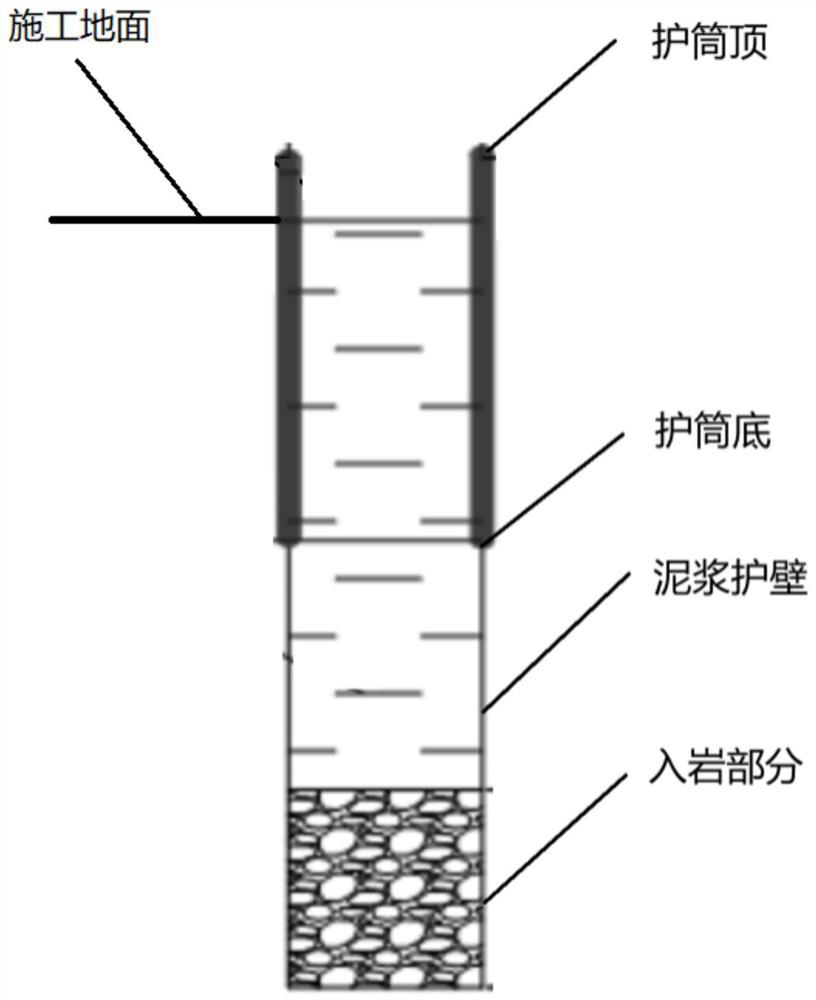

Construction method of reinforced concrete cast-in-place pile under complex geological conditions

PendingCN114703831ALow costReduce work intensityExcavationsBulkheads/pilesWater leakageReinforced concrete

The invention relates to the technical field of building construction, in particular to a construction method of a reinforced concrete cast-in-place pile under complex geological conditions, which comprises the following steps: S1, leveling a site, and paying off a pile position; s2, hole forming and soil taking are conducted, and a steel casing is installed to the position X m away from the natural terrace; s3, slurry retaining wall construction; s4, rock entering, pipe pulling and hole cleaning; s5, placing a reinforcement cage; s6, concrete pouring; and S7, post-grouting, inspection and acceptance. The steel casing and slurry retaining wall cast-in-situ bored pile construction technology is adopted, the problems that under the complex geological conditions of the super-thick coal ash layer, a cast-in-situ pile is prone to hole collapse and drill burying, hole collapse due to vibration during rock entering, water source shortage, serious water leakage, poor retaining wall forming and the like are solved, the cost and the working intensity are greatly reduced, and the construction efficiency is improved.

Owner:CHINA SHANXI SIJIAN GRP

A construction method of cast-in-place pile

ActiveCN110700245BDecrease the filling factorHigh strengthBulkheads/pilesRebarUltimate tensile strength

The invention discloses a construction method of cast-in-situ piles, which aims to solve the problem of excessive leakage of concrete to the inner wall of the pile hole due to the large filling coefficient of the inner wall of the pile hole in the existing technology of cast-in-situ piles, thereby reducing the cost of pouring The technical problem of pile strength; the process of this construction method is: driving the casing casing into the ground at the ground position of the designed cast-in-place pile, and digging out the soil and sand in the casing casing; Vibrate and squeeze the vibrator down along the casing casing to penetrate deep into the ground, then take out the vibrator to fill in the soil and compact it; after that, put a reinforcement cage in the pile hole, and pour concrete into the pile hole While pulling out the casing casing, the casing casing will be completely pulled out after the pouring of concrete is completed, and the construction of the cast-in-place pile will be completed after the concrete is completely solidified. This construction method can greatly reduce the filling coefficient around the inner wall of the pile hole, prevent the concrete in the pile hole from leaking too much to the outside, and thus improve the strength of the cast-in-place pile.

Owner:江西思绮建筑工程有限公司

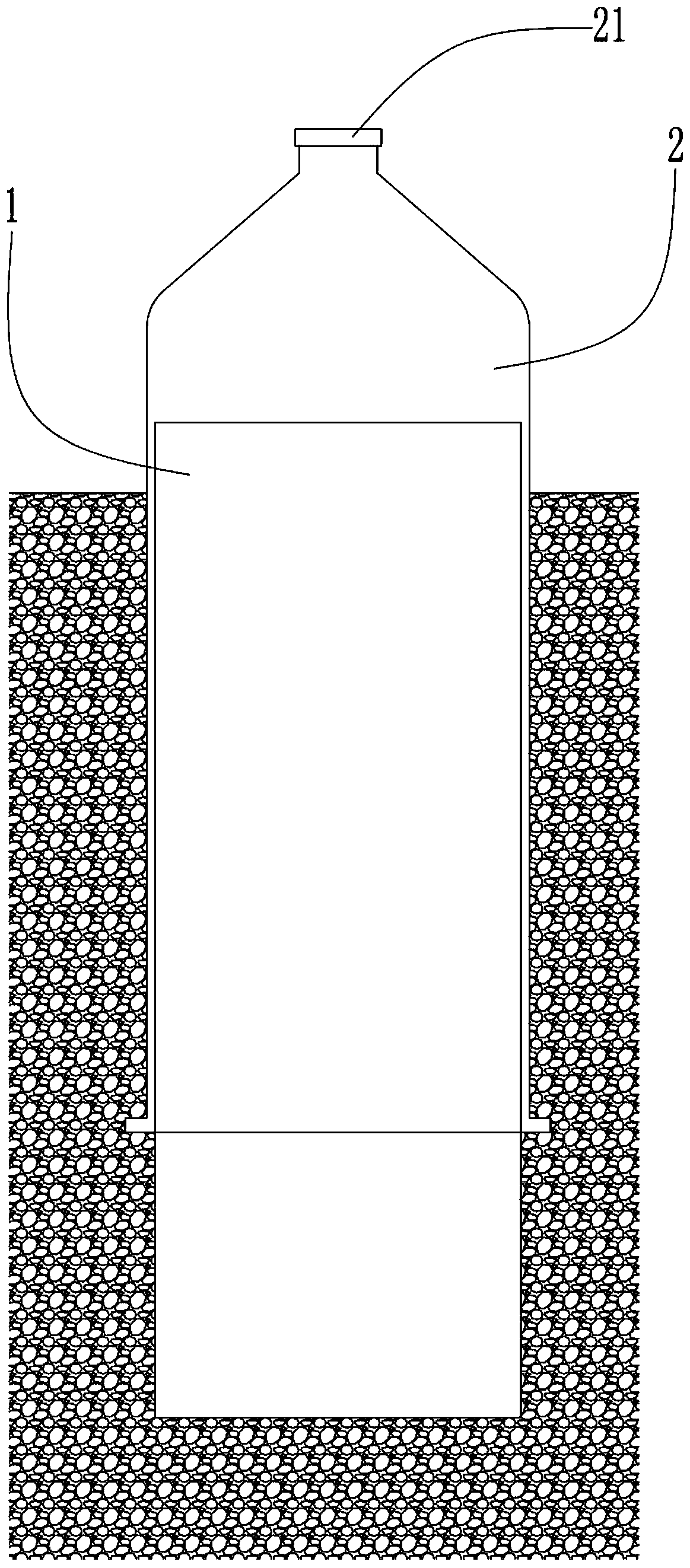

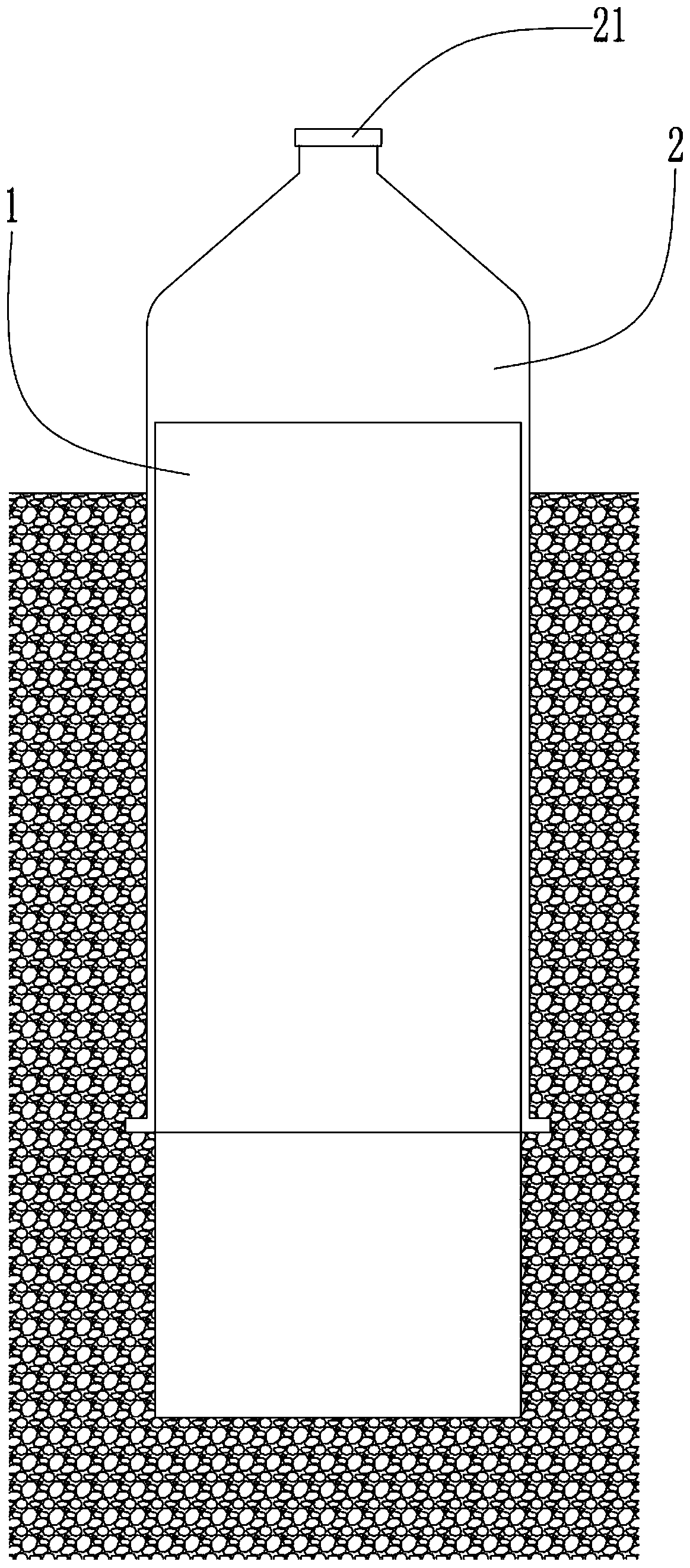

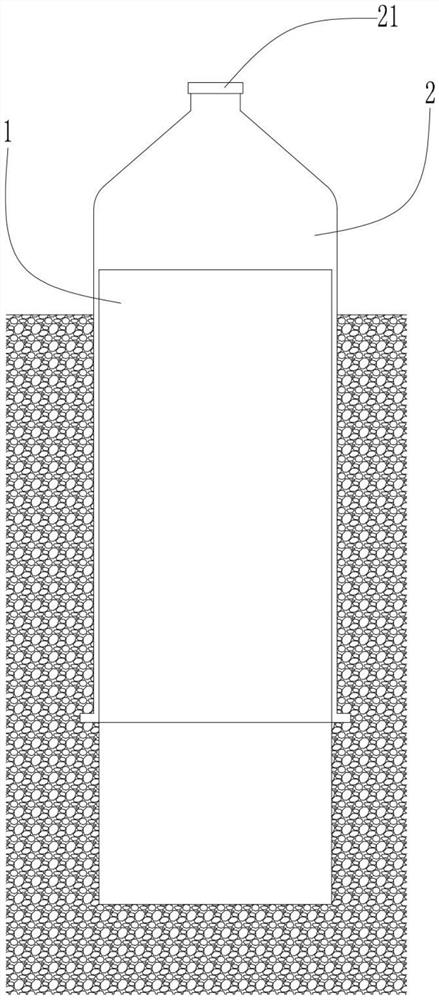

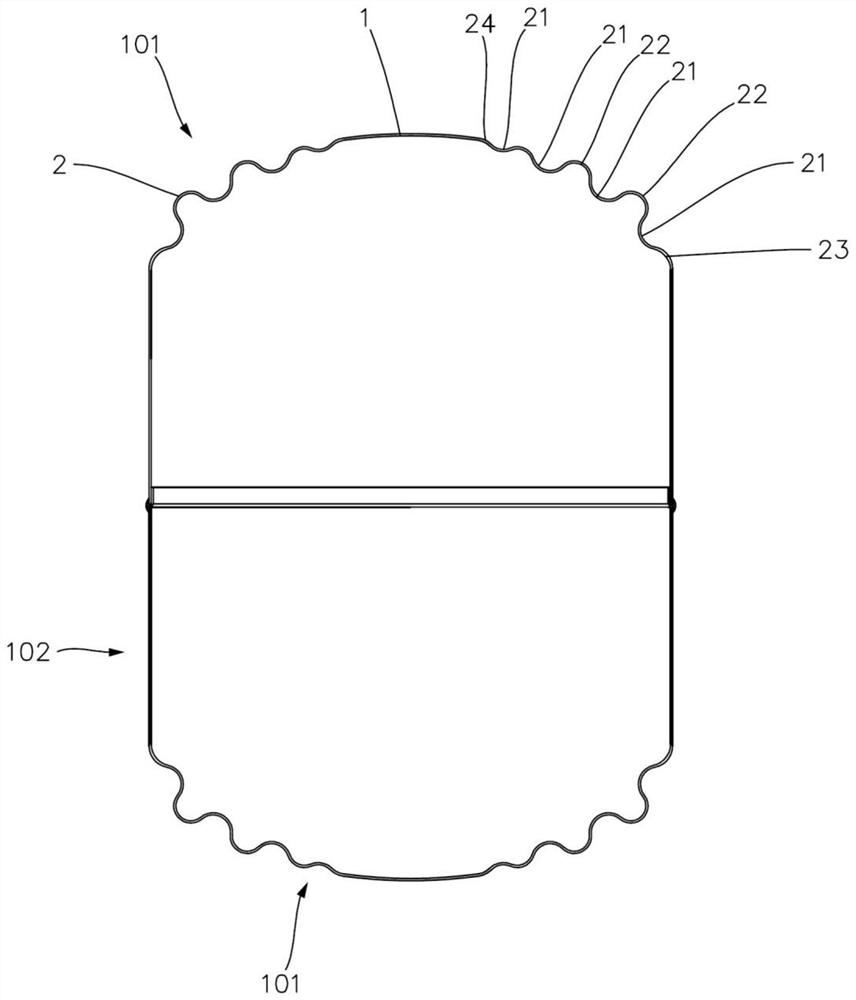

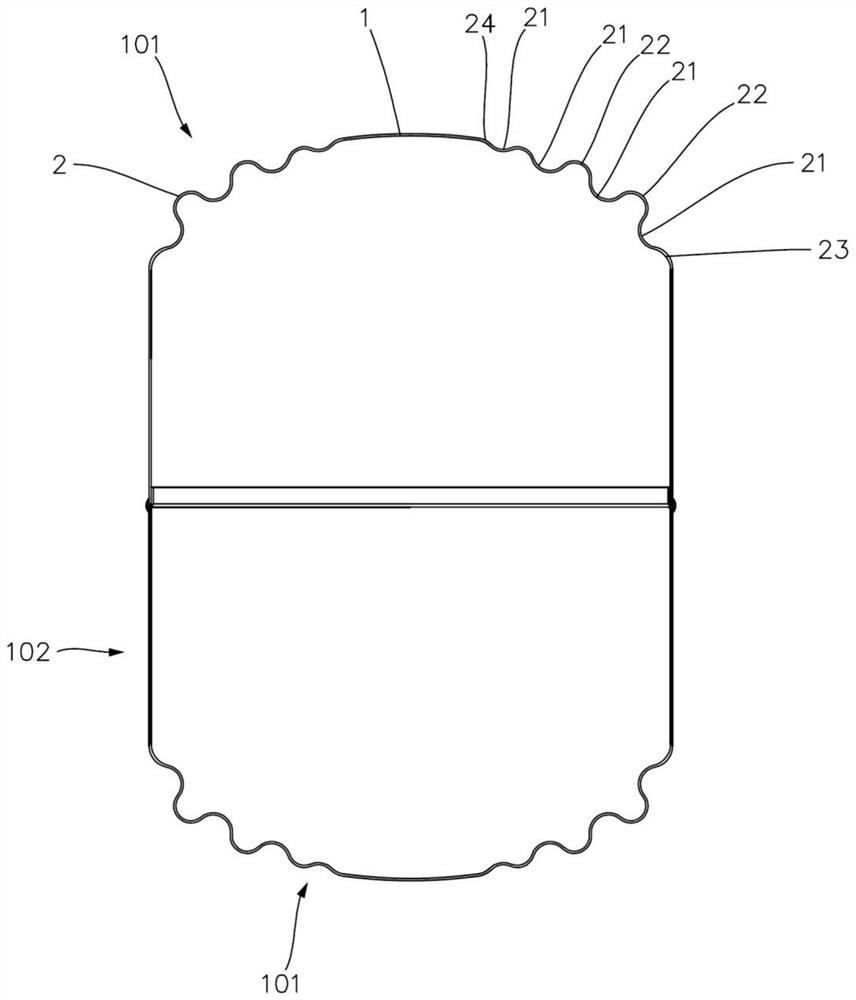

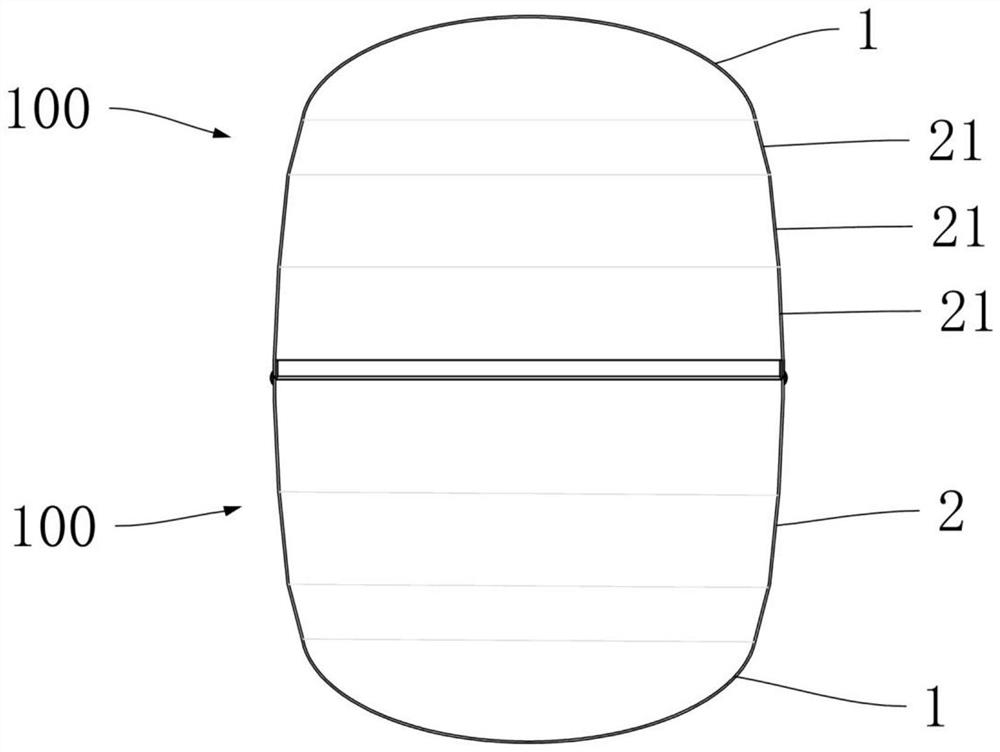

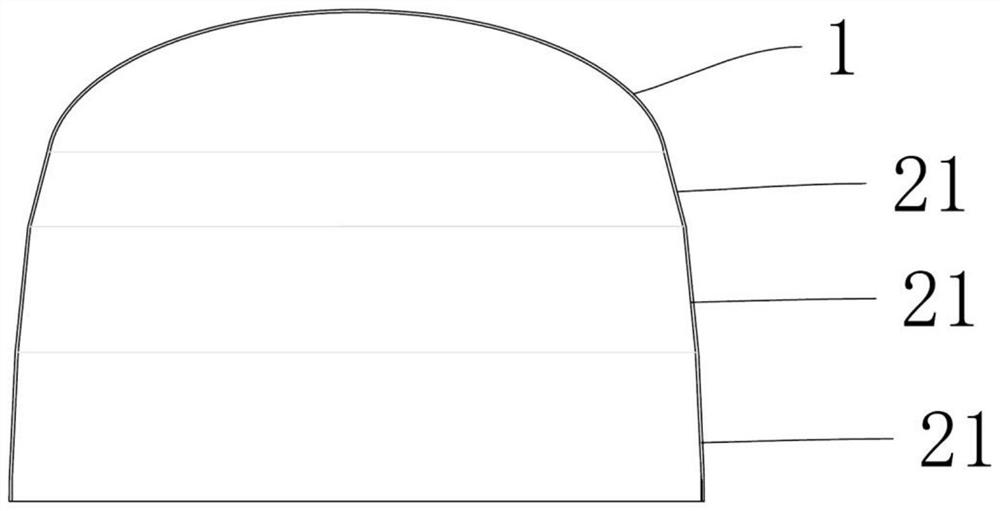

High strength corrugated pressure bottle

ActiveCN113236957BIncrease internal pressureHigh strengthVessel mounting detailsVessel geometry/arrangement/sizeInternal pressureEngineering

The invention relates to a pressure vessel, in particular to a high-strength corrugated pressure bottle. A high-strength corrugated pressure bottle is characterized in that it includes a bottle body, the bottle body includes a sealing head located at the end and a bottle body with the same cross-sectional shape and size everywhere, and the sealing head is formed with a body facing the bottle. A groove-shaped structure on the side, the sealing head is composed of an inner circular part and an outer ring part, the axis of the bottle body part is located on the inner circular part, and the outer ring part is connected to the outer circumferential side of the inner circular part, so The outer ring portion is connected with the bottle body portion, and the outer ring portion has a plurality of inner concave ring segments adjacent to the bottle body portion. The outer ring portion is concave to form the inner concave ring segment, and the inner concave ring segment surrounds the outer ring portion once. The invention has the advantages of being able to withstand higher internal pressure and improving the safety of use.

Owner:ZHEJIANG KIN SHINE TECH

Multi-hopper pile die for pipe sinking cast-in-place pile and construction method

The invention discloses a multi-hopper pile die for a pipe sinking cast-in-place pile. The pile die is provided with two or more than two movable feeding hoppers, each movable feeding hopper is movable, and each feeding hopper consists of three steel plates, wherein one steel plate is positioned on the front side, two steel plates are positioned on the lateral surface, and the steel plates are fixed by welding; the pile die is provided with feeding holes at the positions of the feeding hoppers; the steel plate on the front side is slightly larger than the feeding holes; and the feeding hoppers are uniformly arranged on the pile die, and the distance between the two adjacent feeding hoppers is 2 to 5 meters. The invention also discloses a construction method for the multi-hopper pile die. The construction method comprises the technical steps of: arranging the pile die in place, closing the feeding hoppers, sinking the pile die, opening the first feeding hopper, pouring concrete, upwards pulling the pile die, opening the next feeding hopper, pouring the concrete, and repeating the processes till the pile die is completely pulled out. The method is simple to implement; and by the method, the construction efficiency is improved, energy is saved, and the pile forming quality is ensured.

Owner:HOHAI UNIV

High-strength corrugated pressure bottle

ActiveCN113236957AIncrease internal pressureHigh strengthVessel mounting detailsVessel geometry/arrangement/sizeStructural engineeringBottle

The invention relates to a pressure container, in particular to a high-strength corrugated pressure bottle. The high-strength corrugated pressure bottle is characterized by comprising a bottle body, wherein the bottle body comprises end socket parts located at end portions and a bottle body part with the same section shape and size, the end socket parts form groove-shaped structures facing the bottle body part side, the end socket parts are composed of inner circle parts and outer ring parts, the axis of the bottle body part is located on the inner circle parts, the outer ring parts are connected with the outer sides of the inner circle parts in circumferential directions, the outer ring parts are connected with the bottle body part, a plurality of concave ring sections are arranged at the portions, close to the bottle body part, of the outer ring parts, the concave ring sections are arranged at intervals from the bottle body part side to the inner circle part sides, and are sleeved with one another, the outer ring parts are concave inwards to form the concave ring sections, and the corresponding concave ring sections surround each outer ring part by a circle. The high-strength corrugated pressure bottle has the advantage that higher internal pressure can be borne so that the use safety can be improved.

Owner:ZHEJIANG KIN SHINE TECH

Rotary drilling hole forming method by using multi-stage alloy pilot roller bit in complex stratum cast-in-place pile construction

ActiveCN102409978BEasy to processEasy landing and drillingDirectional drillingLow speedSoil mechanics

The invention discloses a strong karst area cast-in-place pile construction method based on a rotary drilling hole forming manner. The cast-in-place pile construction method is characterized by comprising the steps of: (1) drilling into the surfaces of a karst layer and a gravel soil layer by adopting a conventional bit; (2) in combination with the basic theory of rock-soil mechanics, finding out a mathematic relation between an optimized value of inclination of a multi-stage alloy pilot roller bit and a coefficient of sliding friction between a rock-soil material and the interface of the bit; (3) after adopting the conventional bit to dill into the surfaces of the karst layer and the gravel soil layer, changing the conventional bit into the multi-stage alloy pilot roller bit, firstly drilling at high pressure and low speed, and then, after the bit is dilled into the rock for more than 50 cm, drilling at low pressure and high speed until the drilling depth or hole depth satisfies design requirements; (4) optimizing the design of mud specific weight in stages for preventing pile holes from collapsing and improving the bearing capacity of pile foundations; and (5) handling sudden accidents, such as fracture of drilling rods, bit falling, bit burying, fracture of cone palms in holes, accidental falling of cone palms and other small operation tools and the like, in the drilling process by adopting a drill tool overshot and a falling object salvage skip.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

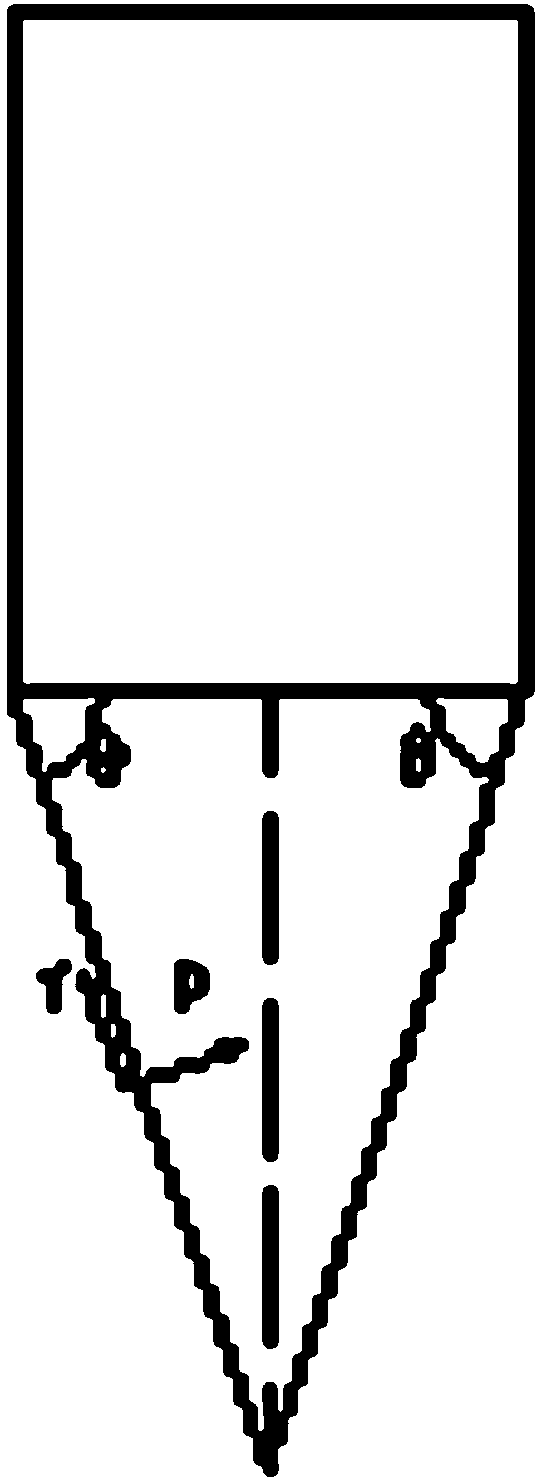

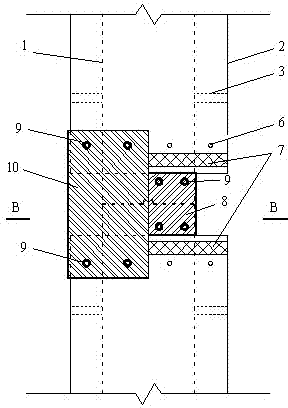

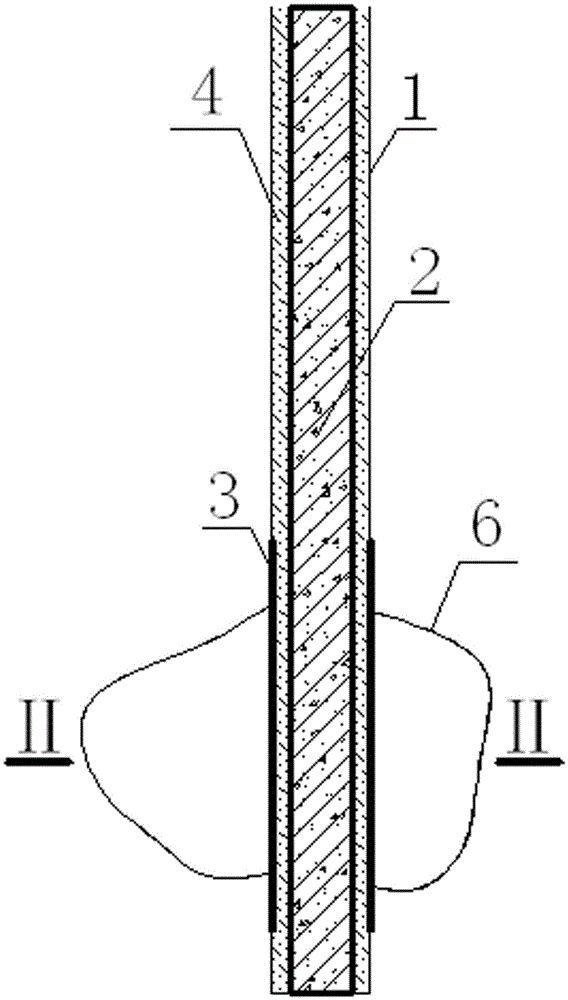

Dual-layer casing connecting section of overlong PCC (cast-in-place concrete large-diameter pipe) pile mould and dip mould connecting method

Owner:HOHAI UNIV

High-safety gas cylinder body

InactiveCN112902006AIncrease filling factorDecrease the filling factorVessel mounting detailsVessel geometry/arrangement/sizeGas cylinderMechanical engineering

The invention relates to a gas cylinder, and particularly relates to a high-safety gas cylinder body. The high-safety gas cylinder body is characterized by comprising an upper half cylinder body and a lower half cylinder body, each half cylinder body comprises a head part and a ring part connected with the head part, the cross section of each ring part is annularly arranged, the axial end of each ring part is integrally connected with the head part, the ring part of one half cylinder body comprises a cone diameter section extending in the axis direction, and the inner diameter of the cone diameter section is gradually increased from close to the head part to far away from the head part. The high-safety gas cylinder body has the advantages that higher internal pressure can be borne, and the use safety can be improved.

Owner:ZHEJIANG KIN SHINE TECH

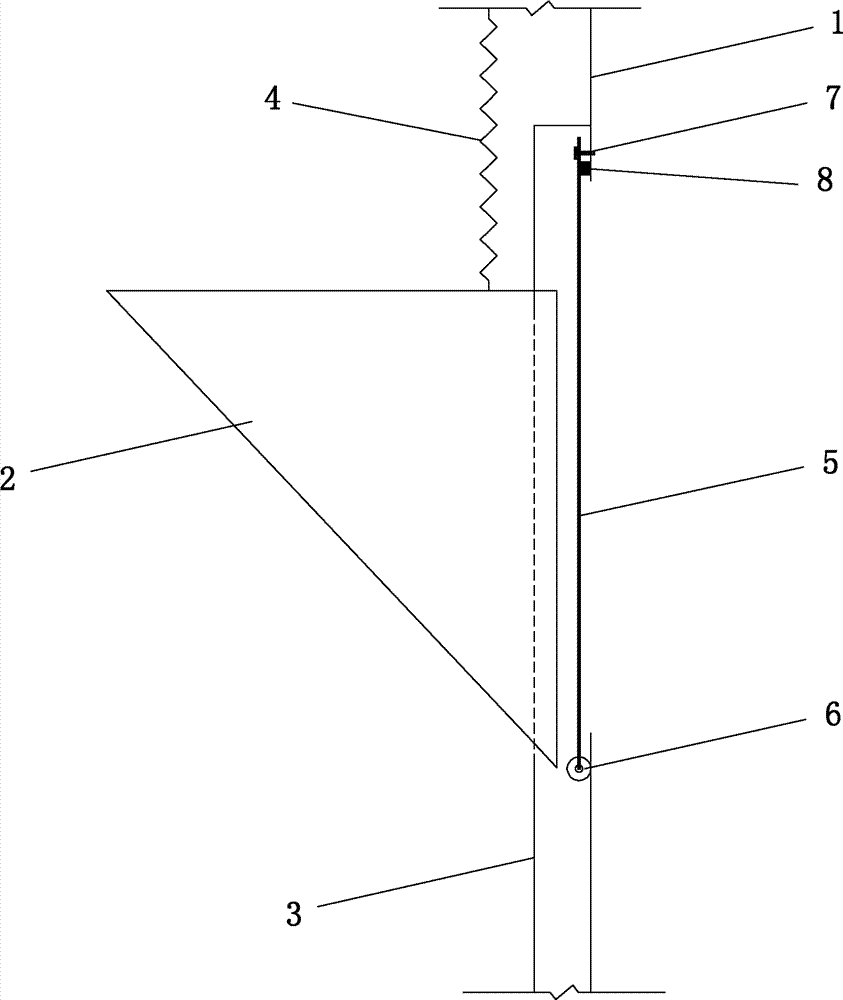

A bored composite pile structure under the geological conditions of karst cave/soil cave

The invention discloses a drilled composite pile structure under geological conditions of karst caves / soil caves, and belongs to the technical field of building pile foundation engineering. The invention consists of boreholes, prefabricated piles, cages, clay cement slurry, grouting pipes, karst caves (soil caves), cage longitudinal reinforcement, cage stirrups and geotextiles. The construction of bored cast-in-situ piles under the geological conditions of karst caves often has great difficulties. The method of drilling can be used to implant prefabricated piles, and then clay cement slurry is filled between the prefabricated piles and the boreholes. That is: firstly, drill holes at the designed pile position, and at the same time, fix the protective cage at the corresponding position on the prefabricated pile according to the burial depth of the karst cave (soil cave) under the pile position. It consists of ring-shaped cage stirrups and geotextiles around the stirrups; then the prefabricated piles are hoisted into the holes to ensure that the center of the prefabricated piles coincides with the center of the drilled hole; finally, the clay cement slurry is injected into the hole through the grouting pipe. In the gap between the pile and the drilled hole, the drilled composite pile is formed after the clay cement slurry is solidified and stabilized.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD +1

Movable feed hopper of tube-sinking cast-in-place pile and construction method

The invention discloses a movable feed hopper of a tube-sinking cast-in-place pile and a construction method. A vertical guide rail is arranged on the outer surface of a pile formwork, the feed hopper is connected with the guide rail through connecting edges extending from the left side and the right side of the feed hopper, the upper portion of the feed hopper is connected with a hauling rope and the feed hopper can slide vertically along the guide rail. Two or more feed inlets are arranged on the pile formwork at a certain interval and disposed along the pile formwork. Openable cover plates are arranged outside the feed inlets and attached to the outer wall of the pile formwork when the pile formwork sinks into the foundation, and are opened when the pile formwork is pulled out and concrete needs to be poured, and sealing strips are arranged among the inner edges of the cover plates and the pile formwork. The construction method includes steps of taking the pile formwork to the place, sinking the pile formwork, moving the feed hopper downwards, opening one of the cover plates of the feed inlets, pouring the concrete, pulling the pile formwork upwards, moving the feed hopper downwards again, opening the next cover plate of the feed inlets, pouring the concrete and repeating the above processes until a pile is formed after the pile formwork is completely pulled out. The movable feed hopper is simple and convenient in operation, construction efficiency is improved, energy is saved and pile forming quality is guaranteed.

Owner:HOHAI UNIV +1

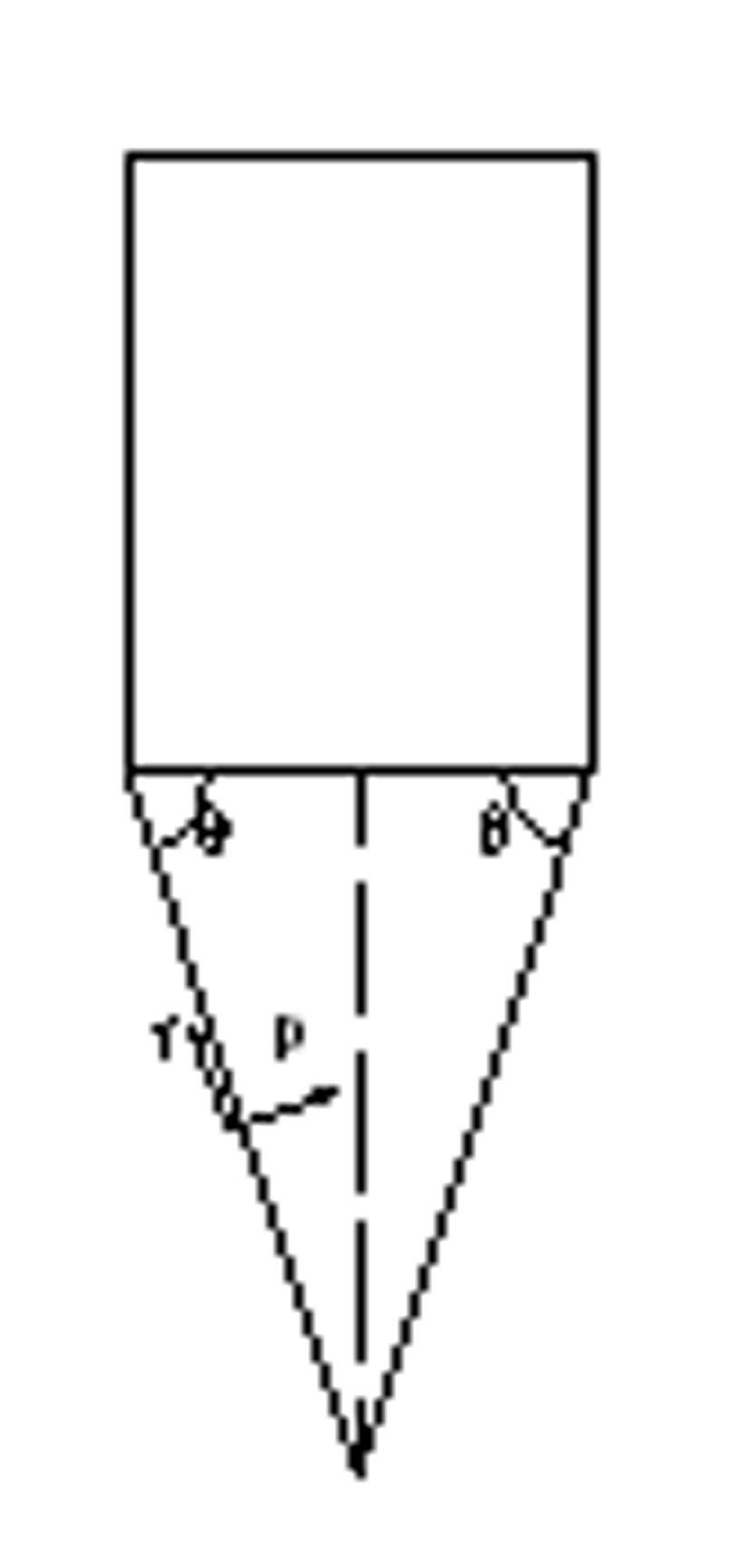

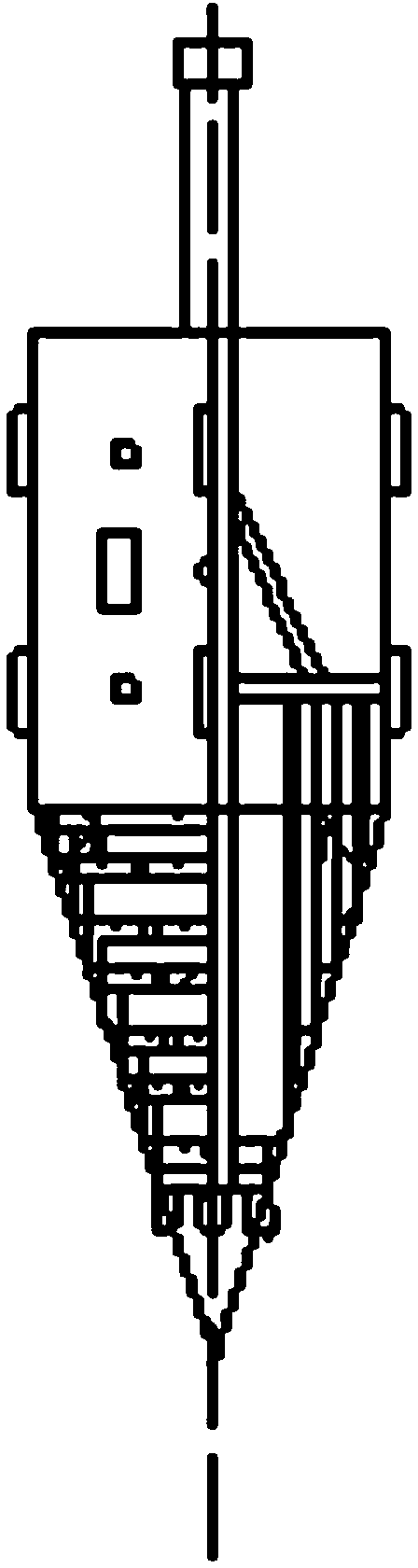

Drill bit

InactiveCN106481279AConvenient construction workQuality improvementConstructionsDrill bitGeotechnical engineering

The invention relates to a drill bit which comprises a drill bit connecting part at the upper end, a drill bit shaft part on the middle part and a drill bit tip part at the bottom end, wherein a connecting hole is formed on the drill bit connecting part; the drill bit tip part has a conical structure; at least one first bulge edge is longitudinally arranged on an outer wall of the drill bit tip part; the first bulge edge extends to the tip part from the upper end of the drill bit tip part; at least one rotating head is longitudinally arranged on the outer wall of the first bulge edge. The drill bit can solve the problems of the present rotating drill bit that the well hole wall is unstable and cannot be drilled and the pile-forming quality is unqualified even if the hole is drilled in the rotary excavating bored pile construction in a high backfilling area.

Owner:YICHANG CHAOYANG CONSTR ENG CO LTD

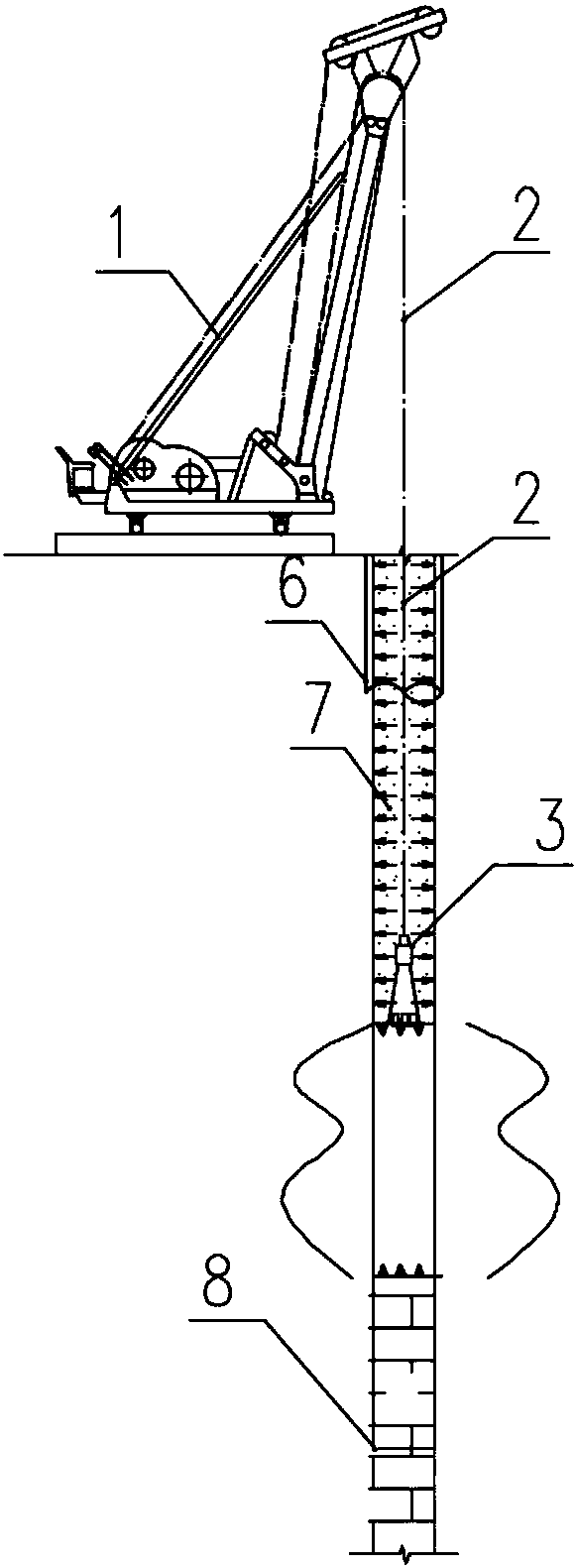

Dry-method rotary extruding and expanding pile forming device and construction method

PendingCN113174935AFast constructionDry construction without mudDerricks/mastsRotary drillingWinchConcrete pump

The invention discloses a dry-method rotary extruding and expanding pile forming device and a construction method thereof. The dry-method rotary extruding and expanding pile forming device comprises a walking type and crawler type main machine, a winch, a cab computer, a guide rod, a steel wire rope, a drilling speed controller, a feeding port, a rotary extruding and expanding drill rod, a rotary extruding and expanding drill bit, a discharging port, a concrete sensing device, a self-soil-taking device, a pump truck guide pipe and a concrete pump truck; the construction method is characterized in that a dry-method rotary extruding and expanding pile is built through the rotary compaction expanding pile forming device to form intermittent expanding of a pile bottom and a pile body, and the specific construction comprises the steps of drilling for hole forming, expanding of the pile bottom, concrete pouring, expanding of the pile body and the like. Compared with the prior art, in a soft soil area drilling process, an original pile body soil body is completely compacted into a pile hole peripheral soil body through the drill bit and the drill rod, hole forming unearthing is reduced, the stability of a pile hole peripheral hole wall is enhanced, the bearing capacity of the pile body is increased, the concrete filling coefficient is reduced, the construction cost is reduced, the construction efficiency of the cast-in-place pile in a soft soil area is improved, and investment and coordination of machinery, personnel and materials are reduced.

Owner:SHANGHAI CHENGDI CONSTR +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com