High-safety gas cylinder body

A high-safety, bottle-body technology, applied in the field of gas cylinders, can solve the problems of high steel cost, low internal pressure, and low safety of gas cylinders, and achieve lower elongation requirements, high internal pressure, and avoid filling Overloaded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and specific embodiments.

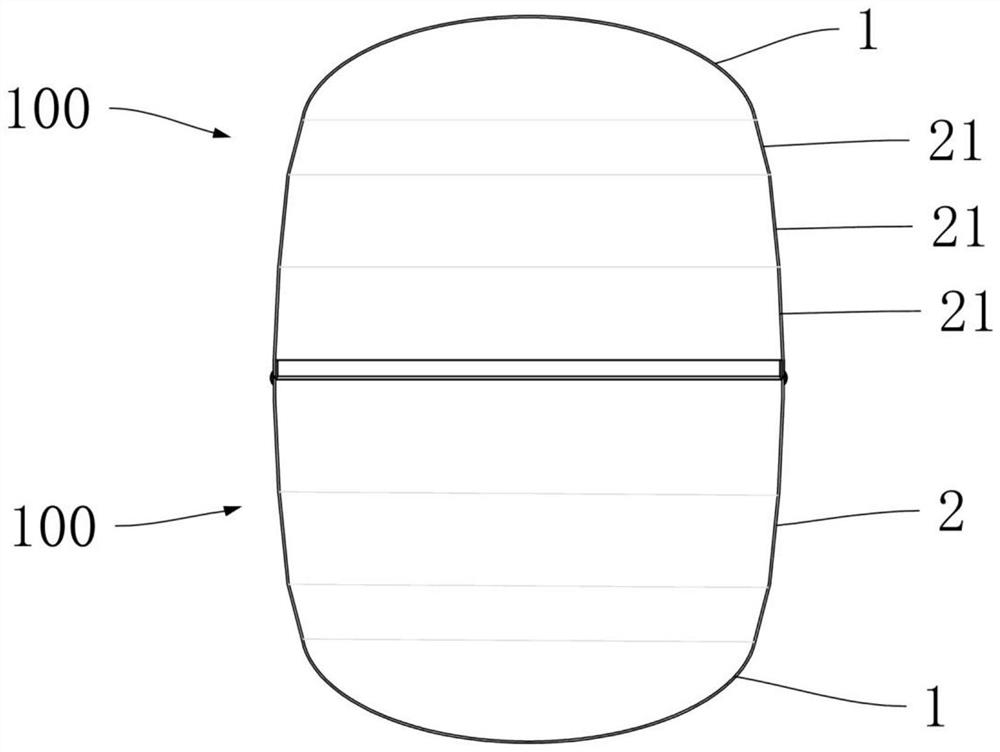

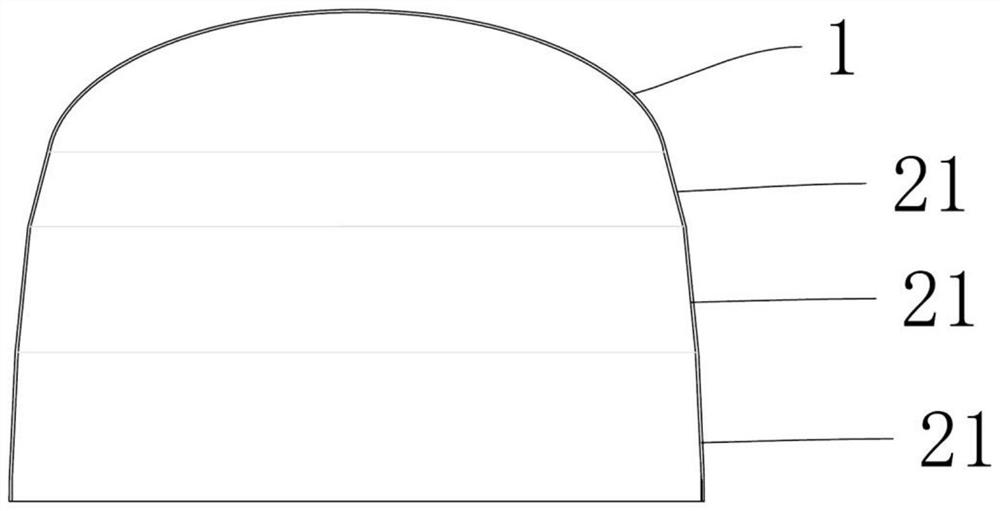

[0016] Depend on figure 1 and figure 2 As shown, a high-safety gas cylinder body of the present invention includes two upper and lower half bottle bodies 100, and the half bottle body 100 includes a sealing head 1 and a ring portion 2 connected with the sealing head 1, and the ring portion 2 is horizontally The cross-section is arranged in a ring shape, and the axial end of the ring part 2 is integrally connected with the sealing head 1. The ring parts 2 of the two half-bottle bodies 100 each include a tapered diameter section 21 extending along the axial direction. From part 1 to part 1 away from the head, it gradually increases.

[0017] Among them, the ring portion 2 has the tapered diameter section 21 adjacent to the sealing head 1, and the ring portion 2 is provided with three tapered diameter sections 21 in sequence along the axial direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com