Self-experiencing expansion pile shoe and immersed tube poured pile re-piling method

A pile shoe and mold tube technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of reducing the bearing capacity of a single pile, dispersing the formation of the pile body, destroying the plastic shape of the foundation, and improving the construction efficiency and engineering. quality, improve the bearing capacity of a single pile, and reduce the effect of soil extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

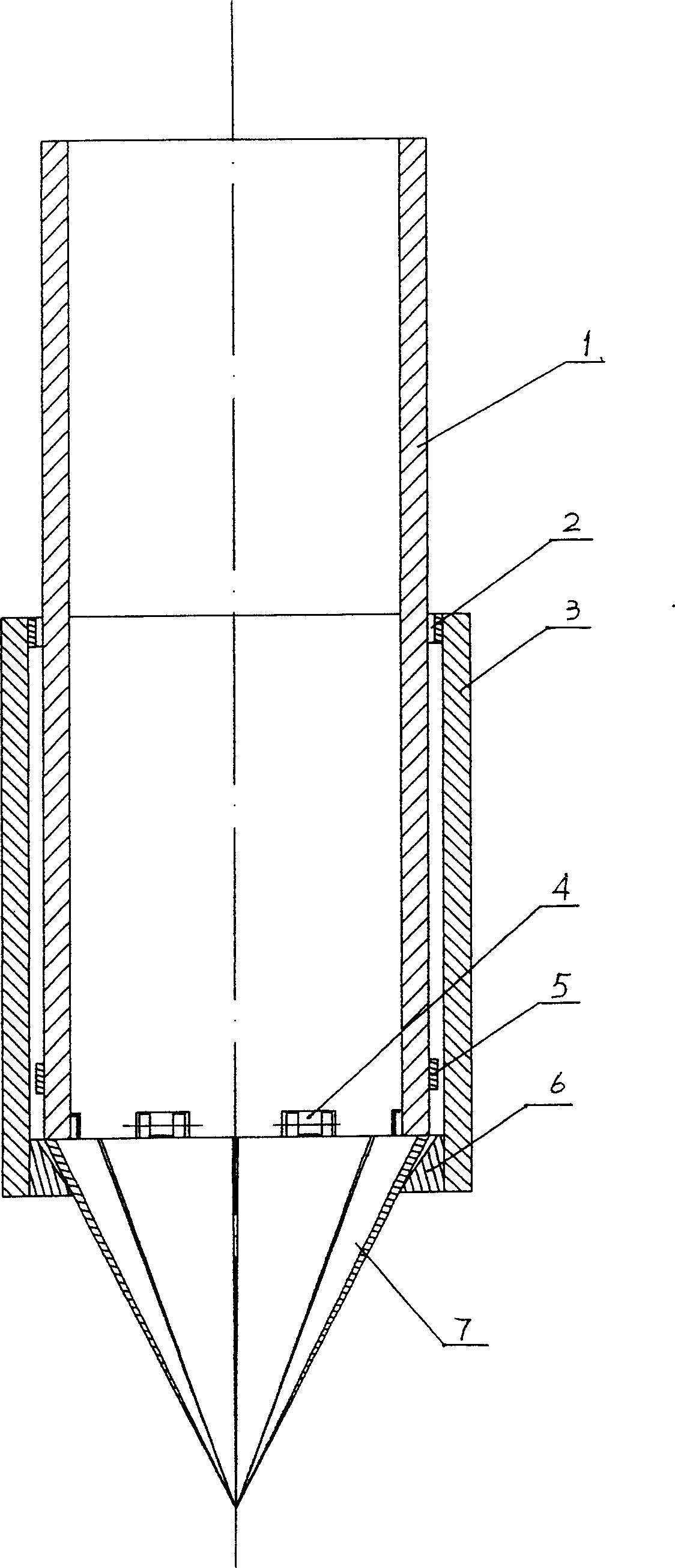

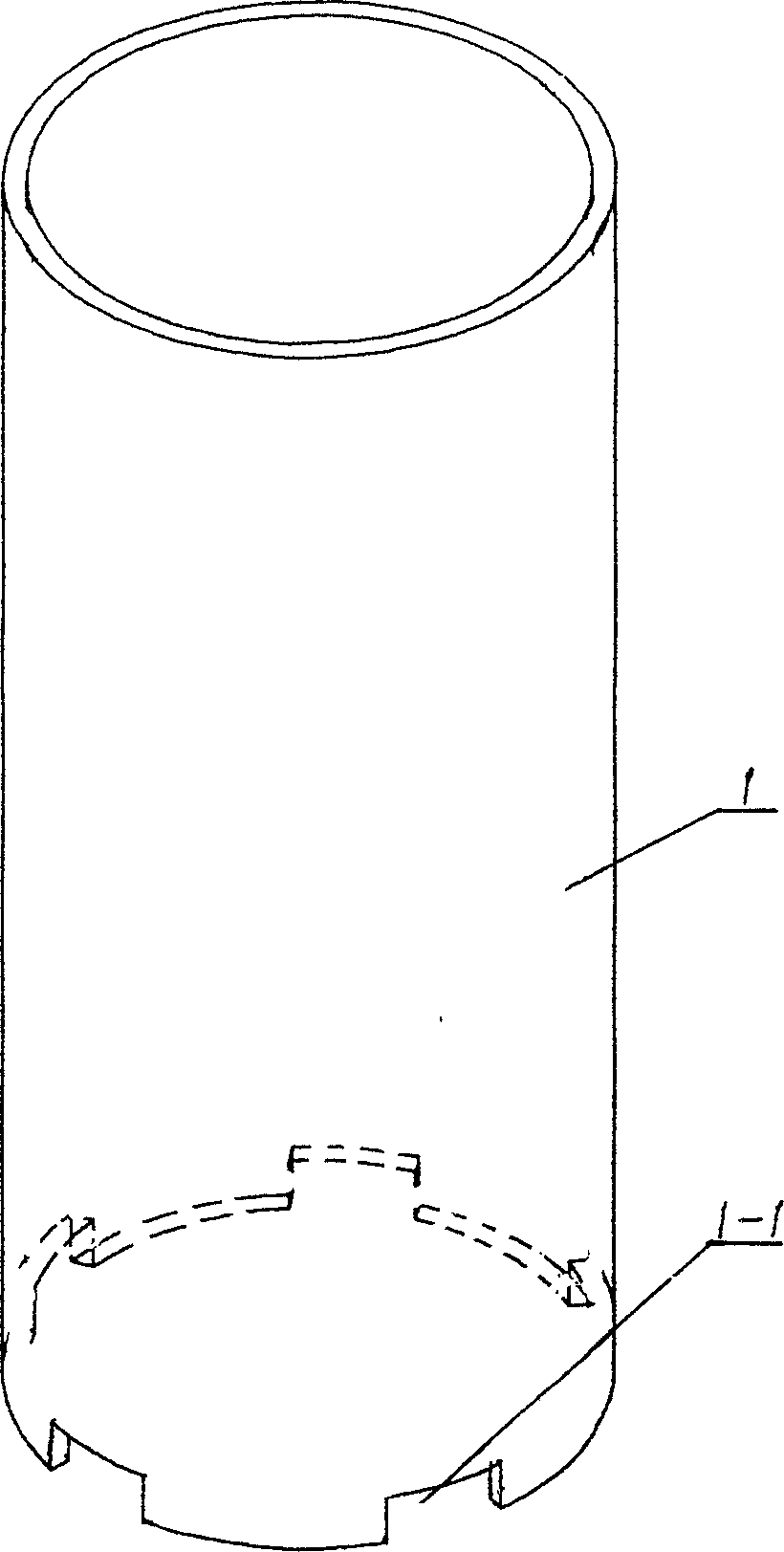

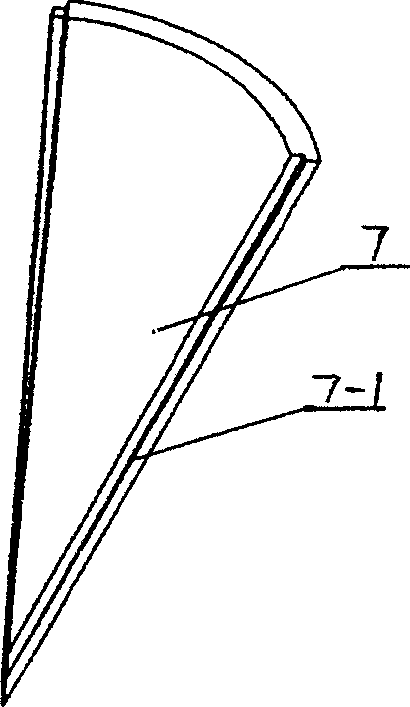

[0012] refer to figure 1 , figure 2 , image 3 , the spud shoe includes a mold tube 1 and a steel sleeve 3, and there are several gaps 1-1 on the periphery of the bottom end of the mold tube 1, in which the hinge 4 is welded, and the movable sleeve of each hinge is welded with an arcuate triangular leaflet 7, Each vane can swing radially, and a locking ring 5 is welded above the gap 1-1 at the lower end of the outer wall of the mold tube 1. The lower end of the mold tube 1 is covered with a steel sleeve 3, and the upper and lower edges of the inner wall of the steel sleeve 3 are respectively welded to the upper positioning ring 2 and the lower positioning ring 6, wherein the inner circle of the lower positioning ring 6 has a large upper and a lower small inclined plane, and is combined with the movable vane 7. Constitutes a conical guiding effect. When the mold tube 1 sinks, the upper bottom of the outer diameter of the vane 7 and the lower positioning ring 6 are tightly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com