Dry-method rotary extruding and expanding pile forming device and construction method

A construction method and piling technology, which are applied in supporting devices, drilling equipment and methods, sheet pile walls, etc., can solve the problems of non-conformity, waste of construction cost, low platform efficiency, etc. force, the effect of reducing the filling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

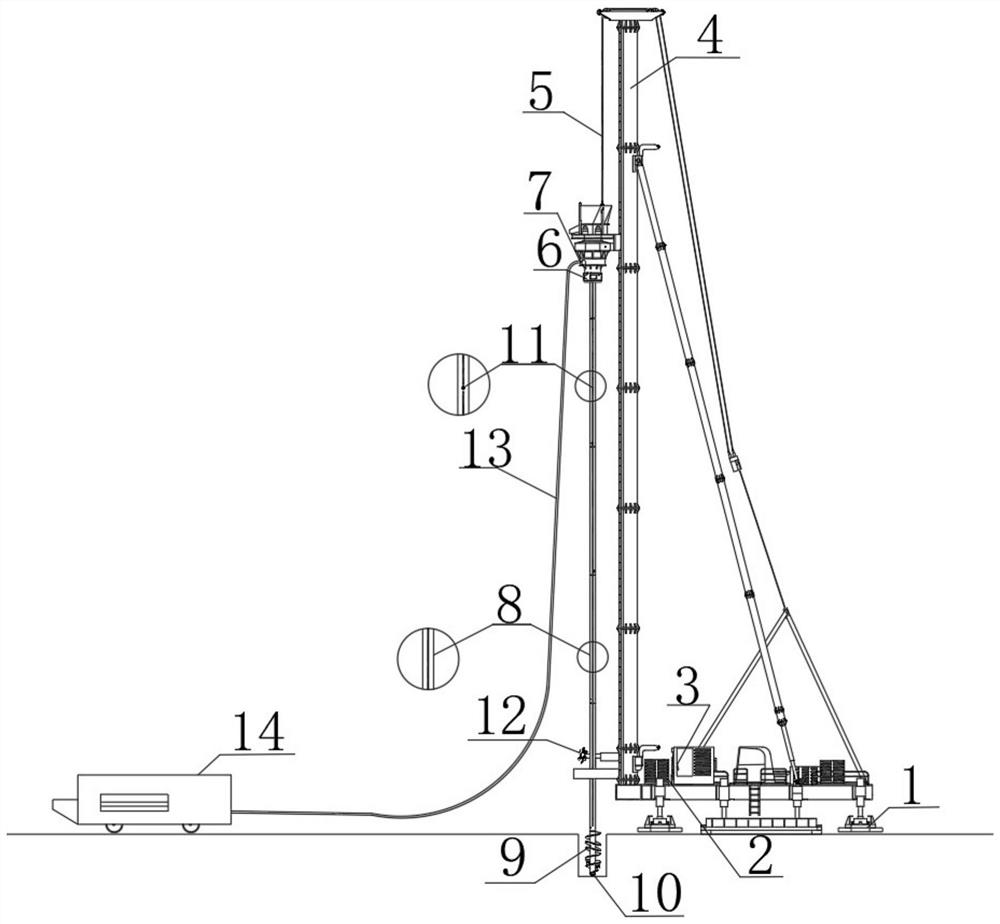

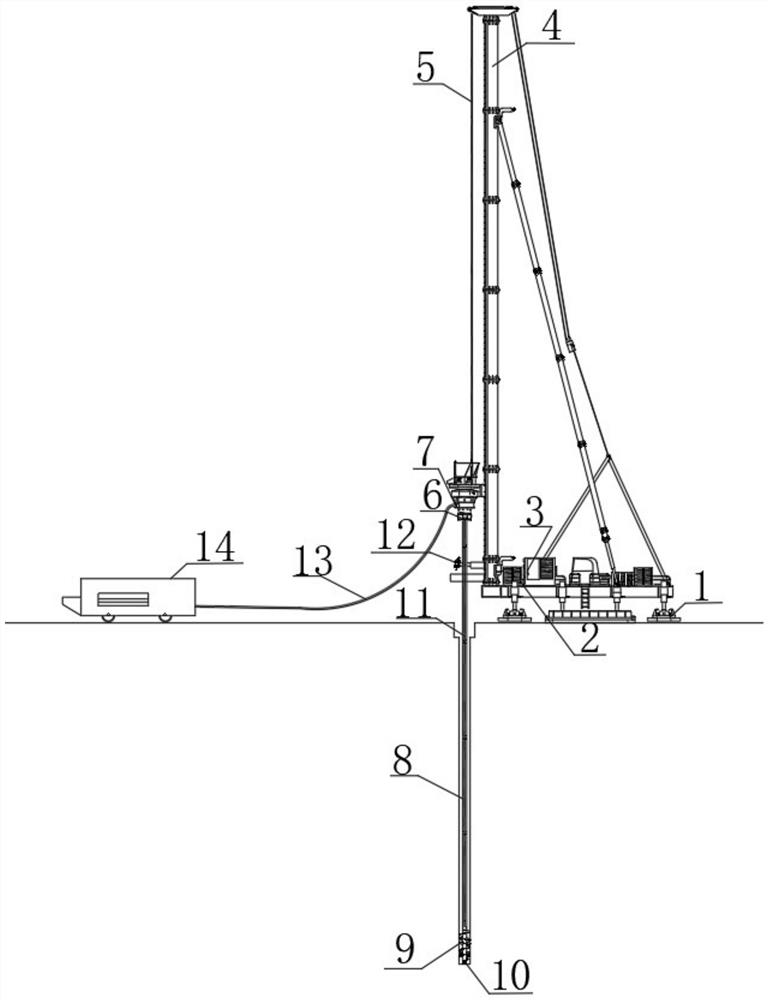

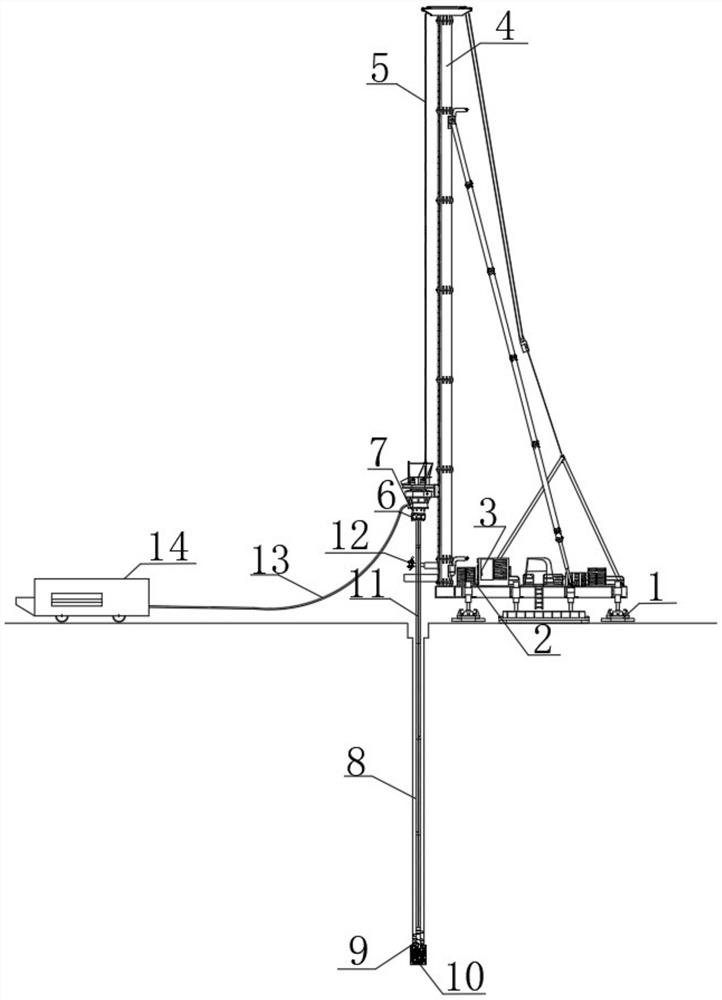

[0030] See attached figure 1 , a dry-process rotary extrusion expanding pile device and its construction method, the device includes a walking and crawler-type main engine 1, a winch 2, a cab computer 3, a guide rod 4, a steel wire rope 5, a drilling speed controller 6, a feed Port 7, Rotary extrusion drill pipe 8, Rotary extrusion expansion drill bit 9, Discharge port 10, Concrete induction device 11, Self-soil extraction device 12, Pump truck conduit 13, Concrete pump truck 14

[0031] A construction method of a dry rotary extrusion pile forming device, characterized in that the rotary extrusion expansion drill bit 9 and the rotary extrusion expansion drill rod 8 cooperate with the drilling speed automatic control system to drill at a low speed, compact the soil around the pile to form a hole, and drill to the bottom of the pile. Expand the diameter of the rotary extruded drill bit 9, lift the rotary extruded expanded drill pipe 8, and inject concrete into the hole through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com