Drill bit

A drill bit and drill shaft technology, which is applied in construction and other directions, can solve problems such as failure to form holes, unqualified pile quality, and unstable well hole walls, and achieve the effects of regular well holes and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

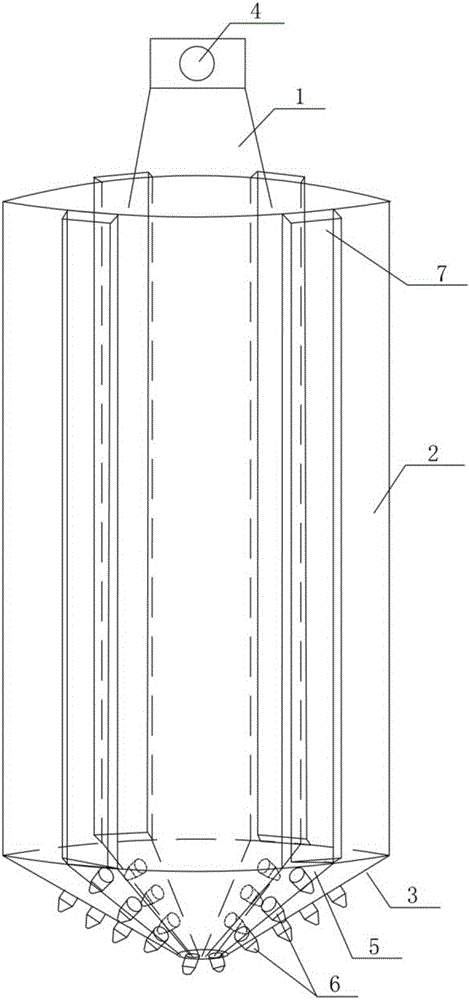

[0019] Such as figure 1 Shown, a kind of drill bit, it comprises the drill bit connection part 1 of upper end, the drill bit shaft part 2 of middle part and the drill bit tip part 3 of bottom end, is provided with connecting hole 4 on the drill bit connection part 1, and described drill bit tip part 3 is tapered structure, the outer wall of the drill tip 3 is provided with at least one first raised rib 5 longitudinally, the first raised rib 5 extends from the upper end of the drill tip 3 to the tip, and the outer wall of the first raised rib 5 is longitudinally provided with at least one 1 swivel head6.

[0020] A second raised edge 7 is provided on the outer wall of the drill shaft part 2 , and the second raised edge 7 is parallel to the central axis of the drill bit shaft part 2 .

[0021] The surface of the second protruding rib 7 is a plane or an arc surface.

[0022] The tip of the drill tip 3 is provided with at least two rotary heads, and the ends of the rotary heads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com