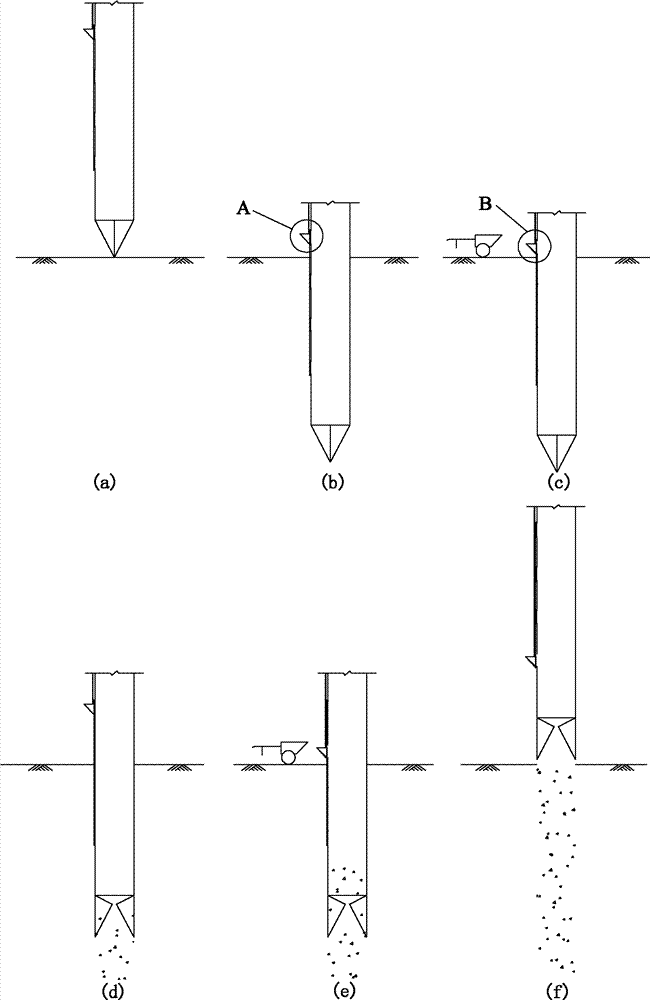

Movable feed hopper of tube-sinking cast-in-place pile and construction method

A technique of sinking cast-in-situ piles and feeding hoppers, which is applied to sheet pile walls, foundation structure engineering, construction, etc., and can solve problems such as increased force of concrete lateral extrusion, increased possibility of segregation, and reduced concrete quality , to achieve the effects of reducing the drop height, saving materials, and reducing the filling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A movable feeding hopper and a construction method of a pipe-immersed cast-in-situ pile according to the present invention are not only suitable for pipe-immersed cast-in-situ piles with circular pile forms (such as solid piles and pipe piles), but also suitable for immersed pipe-grown piles with special-shaped cross-sections ( Such as X-shaped piles, Y-shaped piles, cross-shaped piles, etc.). This implementation example takes a circular sunk pipe cast-in-place pile as an example, but the scope of protection is not limited to the description of this implementation example.

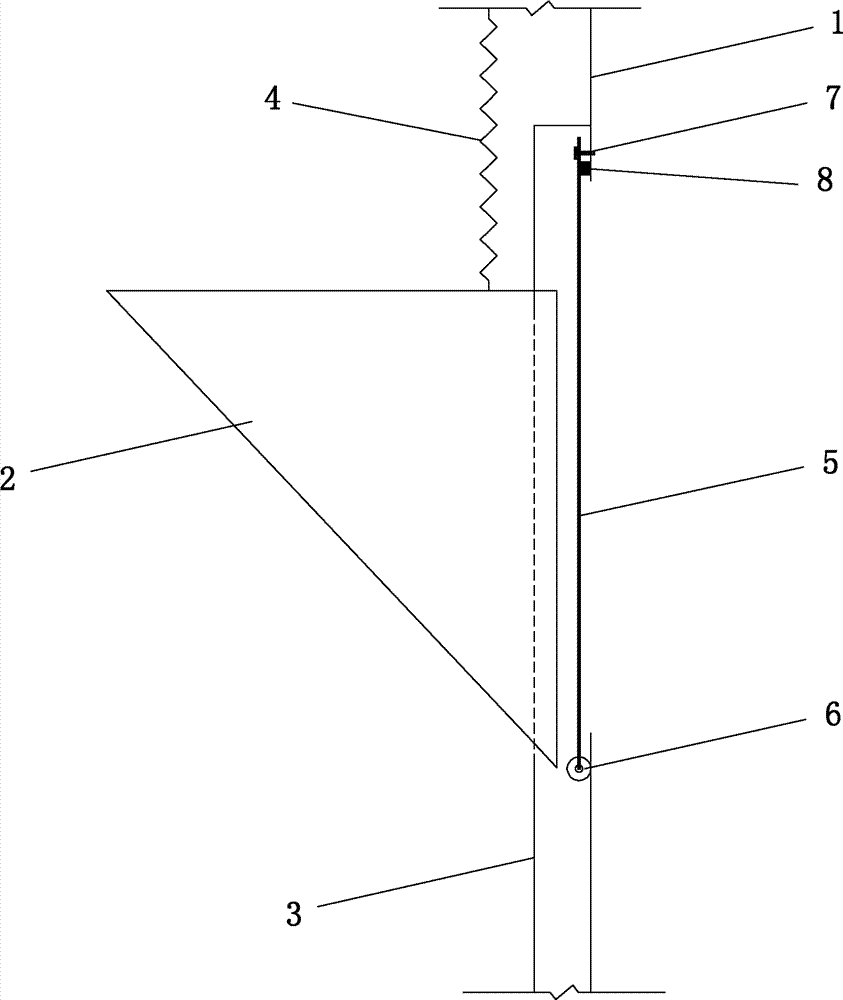

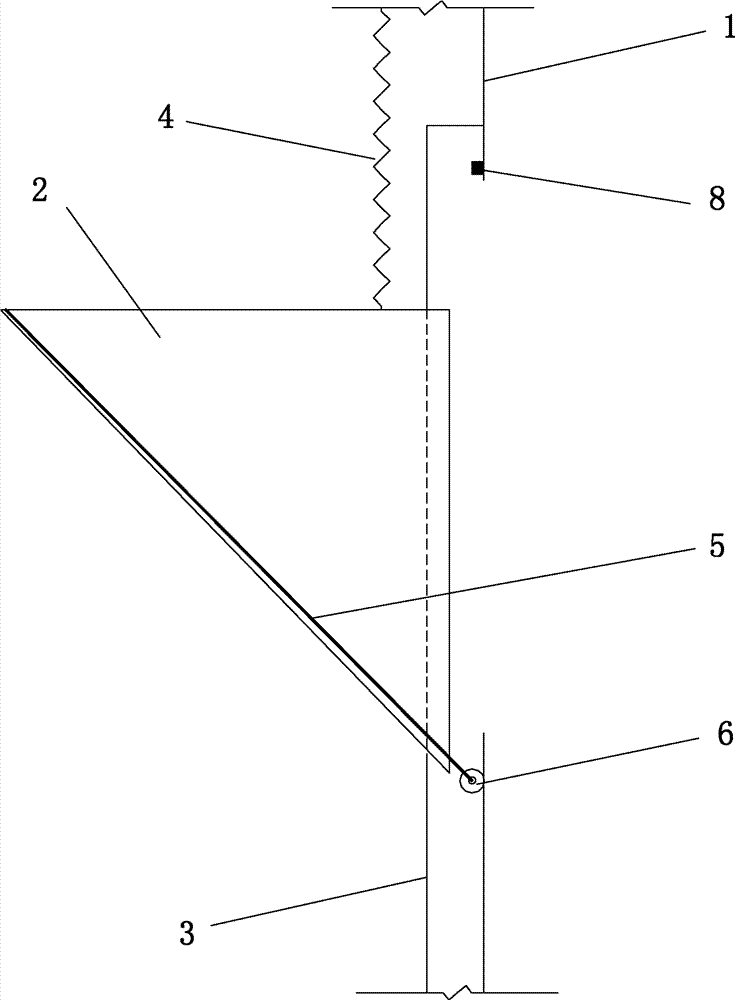

[0047] Such as figure 1 ~ As shown in Figure 7, a movable feeding hopper for immersed pipe pouring piles, two guide rails (3) in the vertical direction are arranged on the outer wall of the pile formwork (1), and the guide rails (3) are welded by two "L"-shaped steel materials On pile formwork (1) (such as Figure 4 and Figure 5 ), the bending section is on the outside. The two guide rails (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com