Construction method of cast-in-place pile

A construction method and technology of cast-in-situ piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reducing concrete strength, concrete leakage, loose soil and sand and gravel filling coefficient, etc., to reduce filling coefficient, prevent leakage, enhance the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

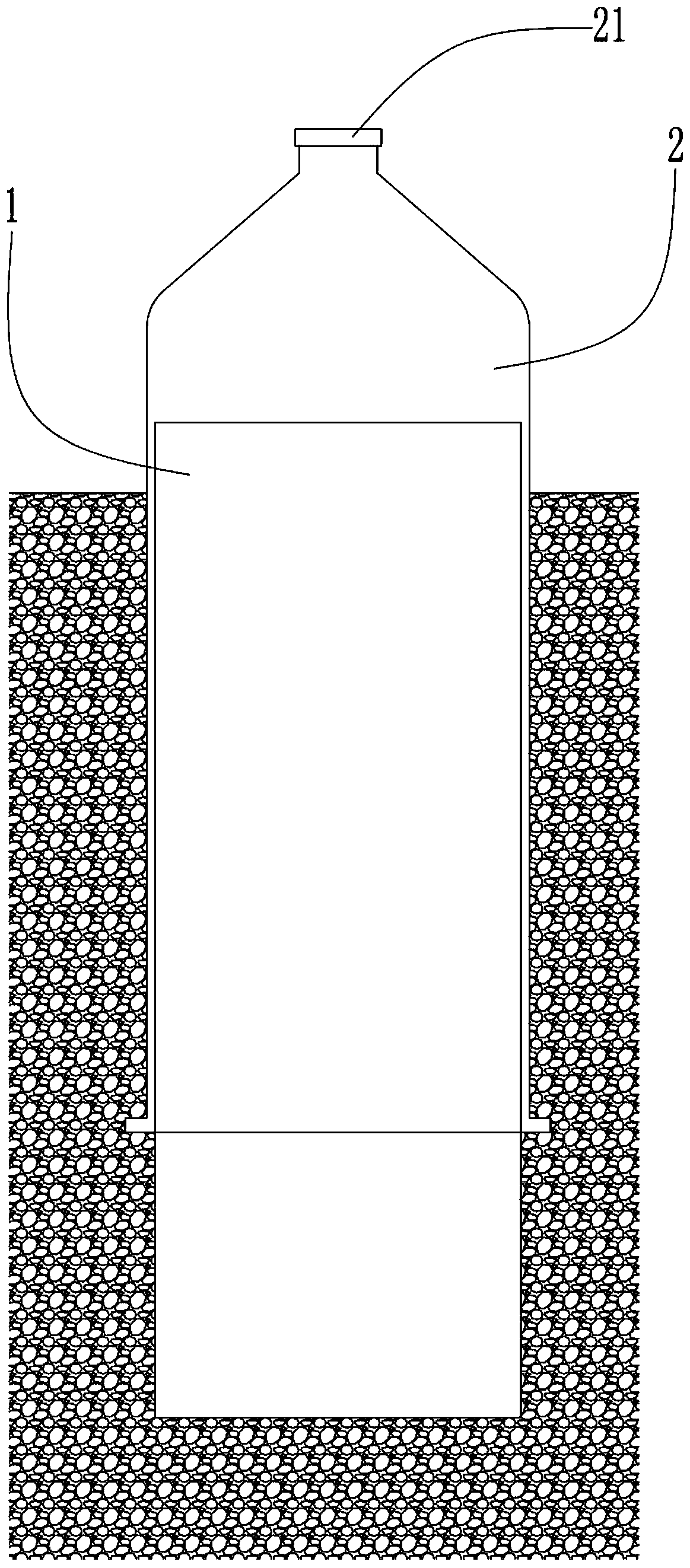

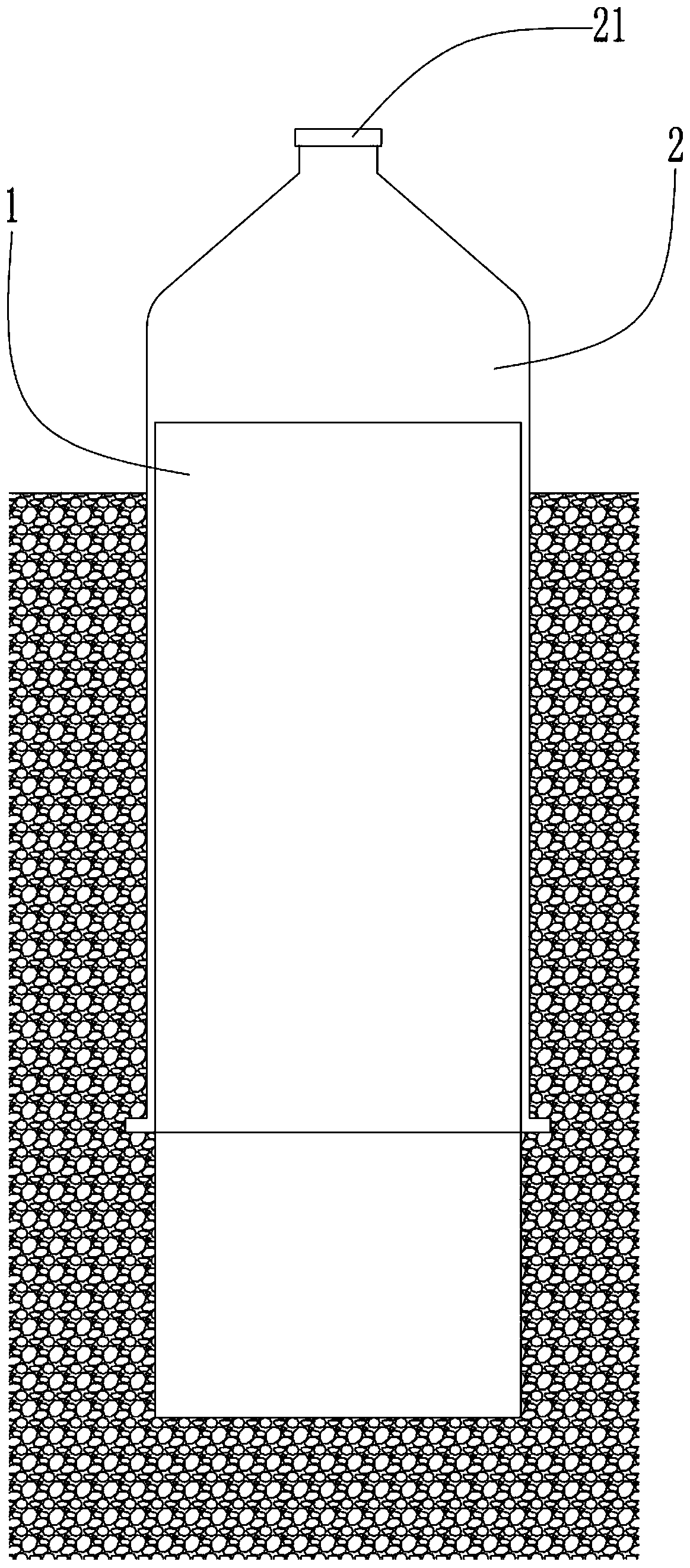

[0020] The specific steps of construction in this specific embodiment are as follows: firstly, on the ground position of the designed cast-in-situ pile, the casing casing is driven into the ground 5m by a hydraulic vibratory hammer, and the soil and sand in the casing casing are dug out by an auger drill , to form a pile hole; then install a shock guide on the outer casing of the casing casing, so that the inner diameter of the shock guide fits the outer diameter of the casing casing, and connect the shock guide to the hydraulic vibrating hammer. The hydraulic vibrating hammer vibrates and squeezes the vibrating guide downward along the casing casing and penetrates deep into the ground, so that the vibration guide moves the soil outside the casing casing and Sand and gravel are crushed and compacted, the vibration frequency of the hydraulic vibrating hammer is controlled to 2500 rpm, the pressure of the hydraulic vibrating hammer is controlled to 70 tons, and then the vibrating...

Embodiment 2

[0022] The specific steps of construction in this specific embodiment are as follows: firstly, on the ground position of the designed cast-in-place pile, the casing casing is driven into the ground 6m by a hydraulic vibratory hammer, and the soil and sand in the casing casing are dug out by an auger drill , to form a pile hole; then install a shock guide on the outer casing of the casing casing, so that the inner diameter of the shock guide fits the outer diameter of the casing casing, and connect the shock guide to the hydraulic vibrating hammer. The hydraulic vibrating hammer vibrates and squeezes the vibrating guide downward along the casing casing and penetrates deep into the ground, so that the vibration guide moves the soil outside the casing casing and Sand and gravel are crushed and compacted. Control the vibration frequency of the hydraulic vibrating hammer to 3000 rpm and control the pressure of the hydraulic vibrating hammer to 50 tons. Afterwards, put the reinforce...

Embodiment 3

[0024] The specific steps of construction in this specific embodiment are as follows: firstly, on the ground position of the designed cast-in-place pile, the casing casing is driven into the ground 8m by a hydraulic vibrating hammer, and the soil and sand in the casing casing are dug out by an auger drill , to form a pile hole; then install a shock guide on the outer casing of the casing casing, so that the inner diameter of the shock guide fits the outer diameter of the casing casing, and connect the shock guide to the hydraulic vibrating hammer. The hydraulic vibrating hammer vibrates and squeezes the vibrating guide downward along the casing casing and penetrates deep into the ground, so that the vibration guide moves the soil outside the casing casing and Sand and gravel are crushed and compacted, the vibration frequency of the hydraulic vibrating hammer is controlled to 3500 rpm, the pressure of the hydraulic vibrating hammer is controlled to 40 tons, and then the vibratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com