Dual-layer casing connecting section of overlong PCC (cast-in-place concrete large-diameter pipe) pile mould and dip mould connecting method

A double-layer casing and connecting section technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of lack of sealing, complicated disassembly, increased wall thickness, etc., to achieve convenient transportation, clever design, and reduced The effect of the filling factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

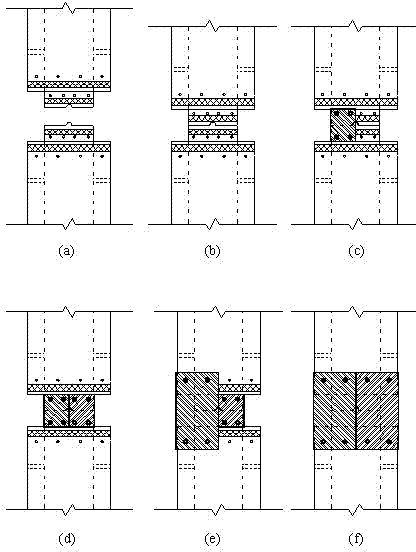

[0029] Such as figure 1 As shown in the present invention, a method for connecting a super-long PCC pile formwork double-layer casing connection section of the present invention uses the connection method of inner length and outer shortness, first inside and then outside to realize the pile form connection, including technical steps: (a) pile The mold is in place, (b) align the inner tubes (1), (c) install the first inner tube connecting plate 8, (d) install the remaining inner tube connecting plates 8, (e) install the first outer tube connecting plate 10 , (f) install the rest of the outer tube connecting plate 10.

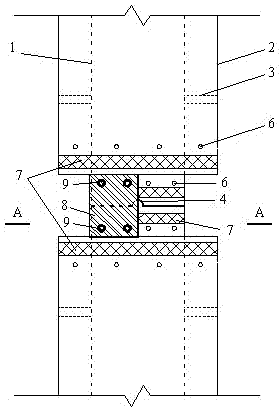

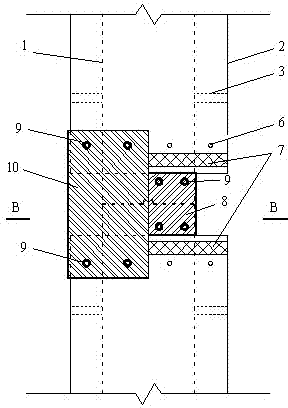

[0030] Such as Figure 2~Figure 6 As shown, the double-layer casing connection section of the pile formwork is a double-layer concentric steel casing including an inner pipe 1 and an outer pipe 2, and a transverse support 3 is arranged between the inner pipe 1 and the outer pipe 2 to fix the pile formwork. The lateral supports 3 can be short steel pipes, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com