Overweight horizontal high-pressure heater hoisting system and hoisting method

A high-pressure heater, horizontal technology, used in track systems, lifting devices, hoisting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

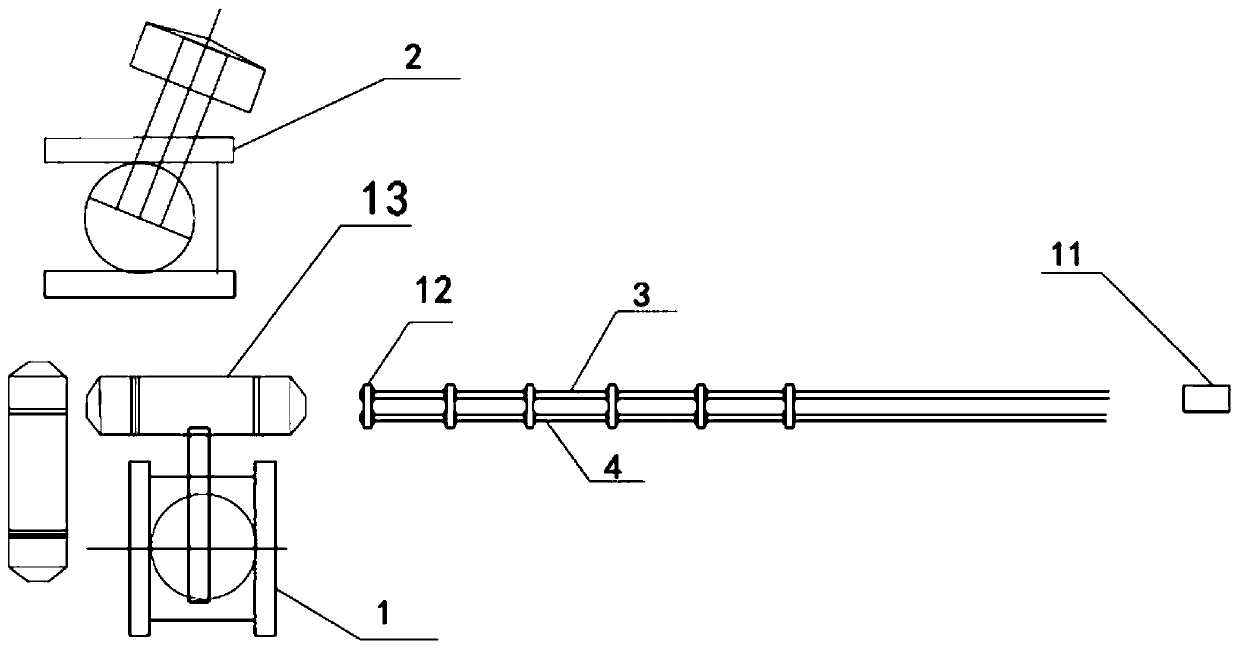

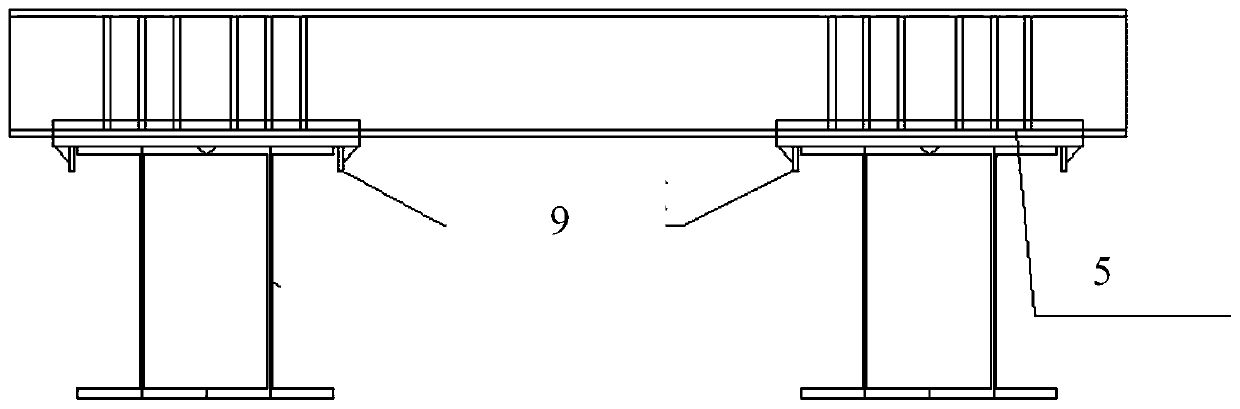

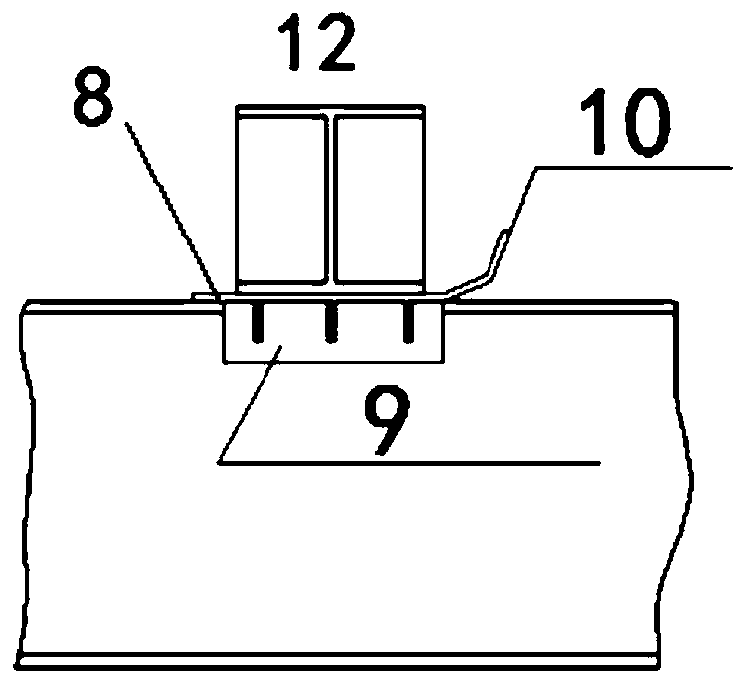

[0047] Object to be hung (overweight horizontal equipment) is an overweight horizontal high-pressure heater 13 with a weight of 320 tons.

[0048] According to the hoisting and positioning scheme of the super-heavy horizontal high-pressure heater 13 designed, the installation of the haulage chute and traction facilities and the arrangement of the two hoisting machines are completed, and the super-heavy horizontal high-pressure heater 13 is determined before entering the site. The loading direction of the heater 13 should be consistent with the plan. After the overweight horizontal high-pressure heater 13, stop the transport vehicle to the unloading position, and use a 600-ton crawler crane and a 450-ton crawler crane to lift and unload the truck; for the convenience of equipment transportation, the manufacturer will The super-heavy horizontal high-pressure heater 13 arrives obliquely. After unloading, the high-pressure heater needs to be turned around. A 600-ton crawler crane a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com