Tatami

A tatami and core layer technology, which is applied to mattresses, other seating furniture, spring mattresses, etc., can solve the problems of consumption of natural resources, decrease in strength of boards, and easy mildew, etc., and achieve a wide range of raw material sources, high strength, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Figure 1 is a front view of tatami mats.

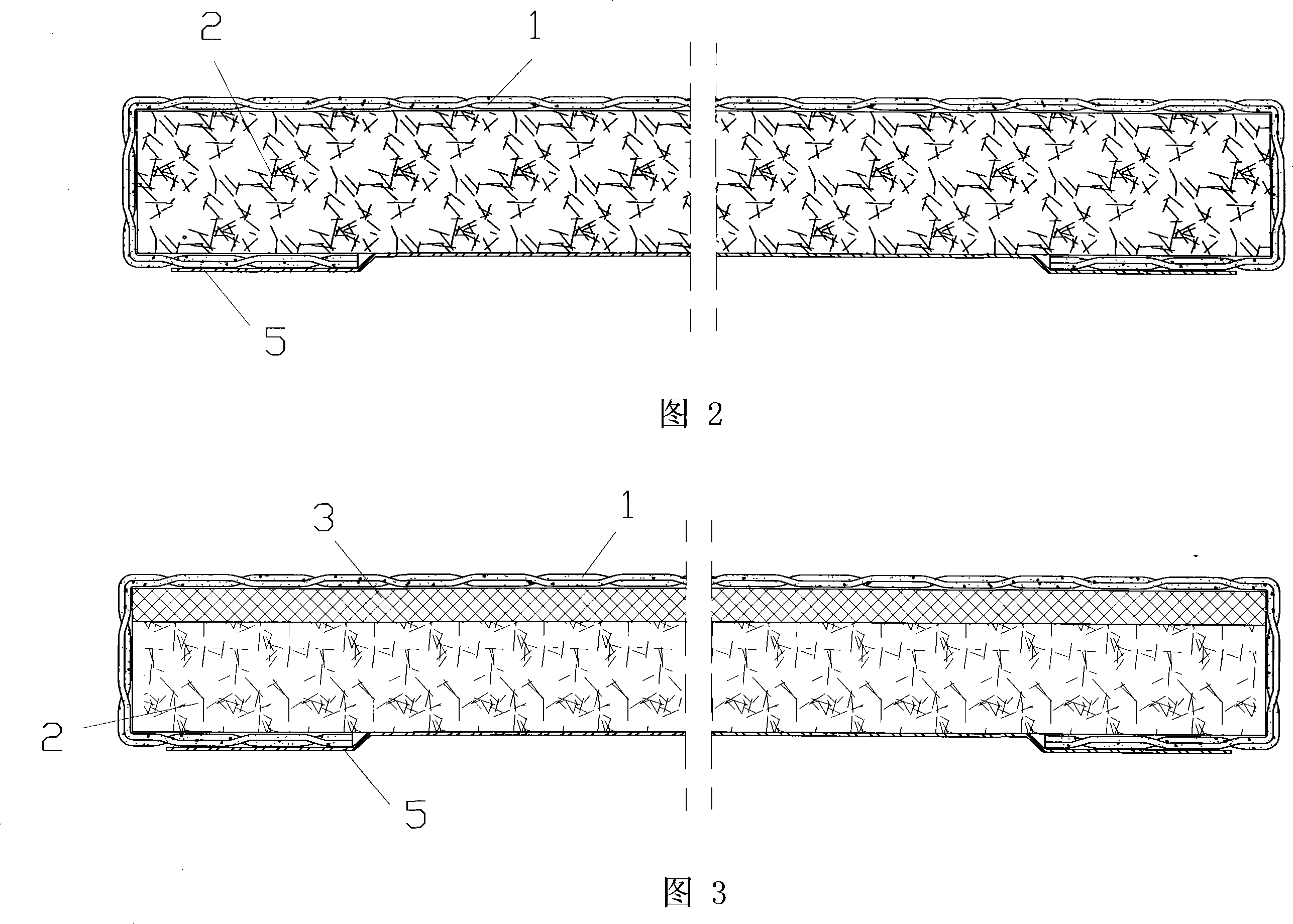

[0021] As shown in FIG. 2, the tatami mat implemented according to the present invention includes a core layer 2 located in the middle, a stacking table 1 located on the upper surface, and a non-slip cloth 5 located on the lower surface. Wherein, the material of the core layer 2 is a wheat straw board, and the wheat straw board is made by bonding and shaping crushed rice and wheat straw with an isocyanate resin adhesive.

[0022] The folding table 1 covers the entire upper surface of the tatami, and wraps the four sides of the tatami, extends to the bottom of the tatami, and is folded inward. The non-slip mat 5 completely covers the lower surface of the core layer 2 and the outer surface of the folded part of the folded table 1 on the bottom of the tatami mat. The function of the anti-slip mat 5 is to prevent sliding between the tatami and the ground or the table top.

[0023] All the above-mentioned structural layers of the tatami...

Embodiment 2

[0025] As shown in FIG. 3, the difference between this embodiment and Embodiment 1 is only that an elastic layer 3 is further provided between the laminated watch and the core layer 2.

[0026] The elastic layer 3 is made of a plurality of polyurethane foam plastic particles with an open-cell structure, which are mixed with the raw material monomers of the polyurethane foam after stirring and uniformly stirred, and then subjected to secondary foaming, and then formed through a forming process and a cutting process. Its function is to increase the comfort of the human body in contact with the tatami.

[0027] The elastic layer 3 can also be made of polyethylene foam plastic particles.

Embodiment 3

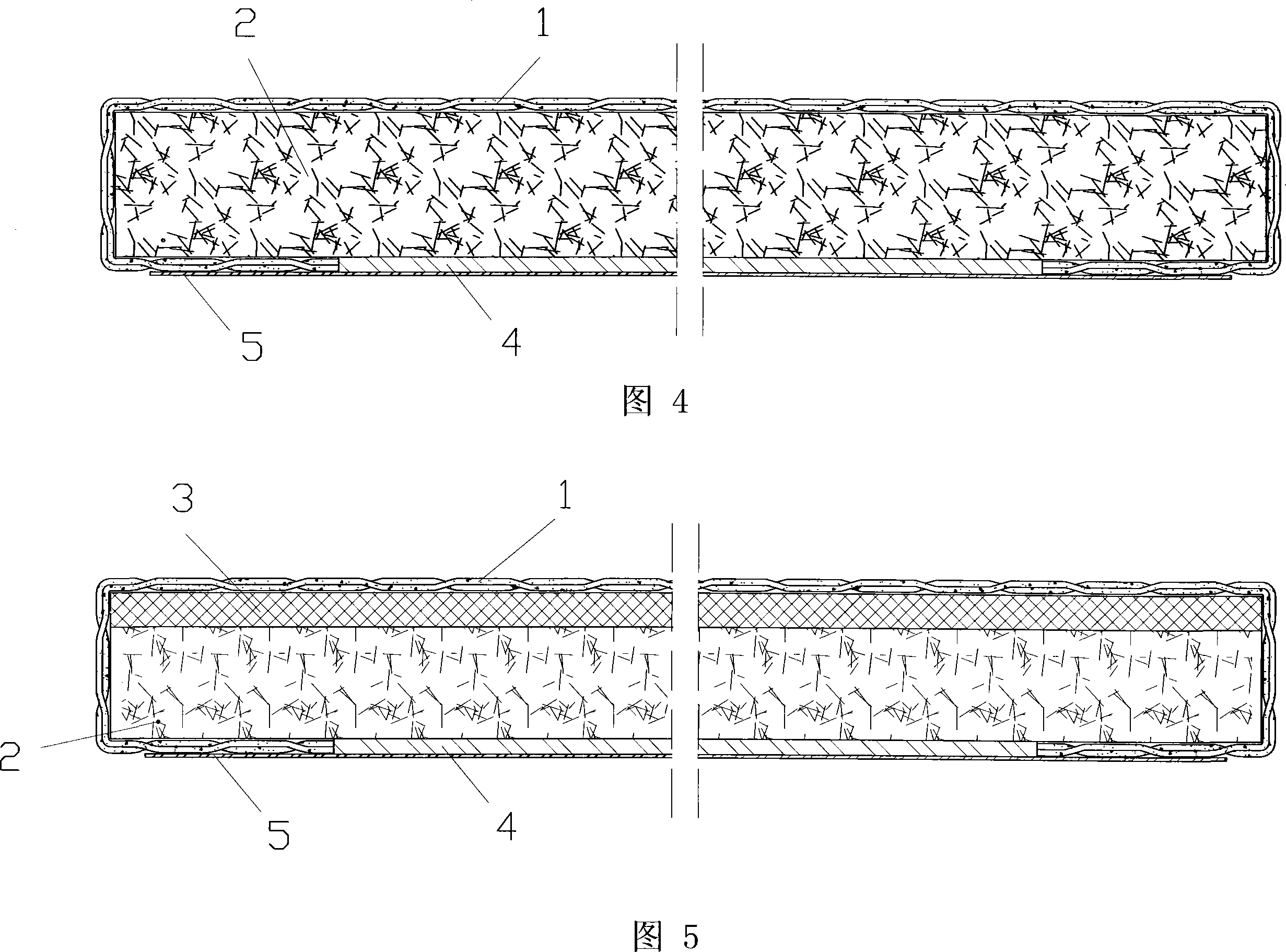

[0029] As shown in FIG. 4, the difference between this embodiment and Embodiment 1 is only:

[0030] A bottom lining 4 is also provided between the core layer 2 and the anti-slip cloth 5. The area of the backing 4 is slightly smaller than that of the tatami, and its edge is in contact with the edge of the folded table 1 that is folded inward. The non-slip mat 5 completely covers the lower surface of the bottom lining 4 and the outer surface of the folded part of the folded table 1 on the bottom of the tatami mat.

[0031] The material used to make the bottom liner 4 can be the same as the material used to make the elastic layer 3, that is, polyurethane foam or polyethylene foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com