Composite rib reinforced ECC-composite square steel tube hollow column

A square steel tube and composite technology, which is used in protective buildings/shelters, building components, climate change adaptation, etc., can solve the problems of brittleness and fragility of the outer concrete, the overall weight of the superimposed column is heavy, and the combination effect is low. , to achieve the effect of superior ability to control cracks, superior seismic performance, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

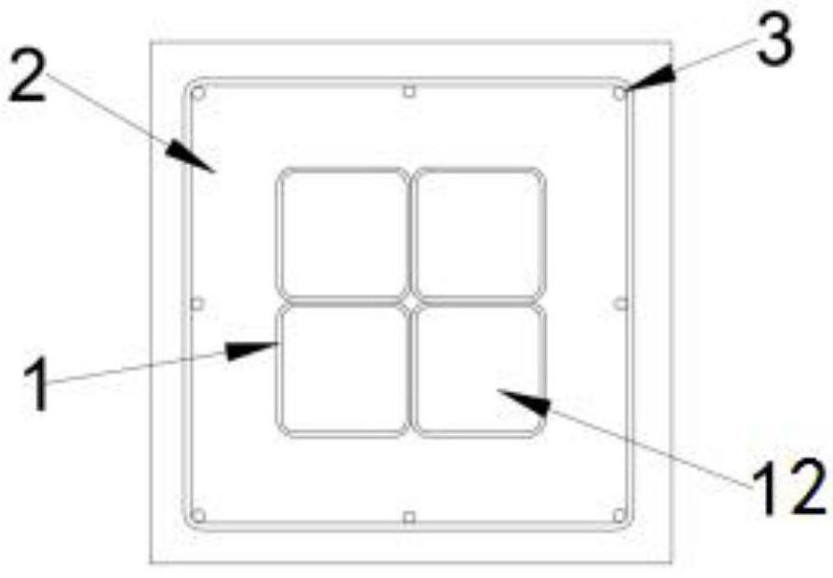

[0028] see Figure 1-3 , a compound-reinforced ECC-compound square steel tube hollow column, comprising a composite square steel tube component 1 , an external ECC 2 , and a composite reinforcement cage 3 .

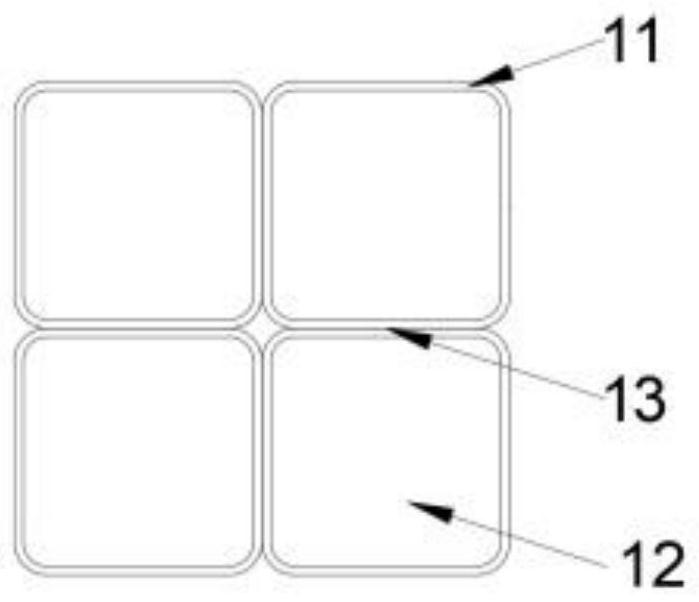

[0029] Such as figure 2 As shown, the composite square steel pipe assembly 1 includes four square steel pipes 11 arranged in the shape of a field, the external ECC2 is outsourced to the composite square steel pipe assembly 1, the axis of the composite square steel pipe assembly 1 coincides with the central axis of the external ECC2, and the composite square steel pipe assembly The end face of 1 is coplanar with the end face of the external ECC2.

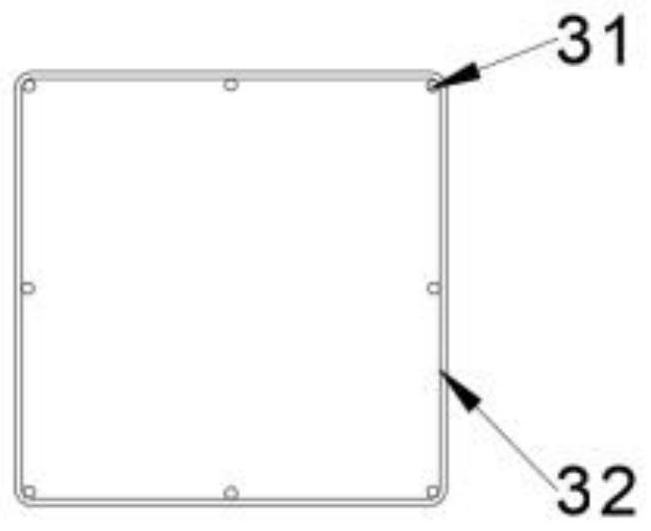

[0030] The composite reinforcement cage 3 is arranged in the external ECC2, and the structure of the composite reinforcement cage 3 is as follows image 3 As shown, the composite reinforcement cage 3 is formed by connecting the longitudinal reinforcement 31 and the FRP stirrup 32. The inner side of the FRP reinforcement 32 ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com