Anti-seismic crisscross-inclined-slot corrugated-steel-plate shear wall

A technology of corrugated steel plates and criss crosses, applied to walls, earthquake resistance, building components, etc., can solve the problems of reducing energy consumption of steel plates and stress concentration of steel plates, so as to weaken stress concentration, improve seismic performance, and avoid internal casualties and facilities damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

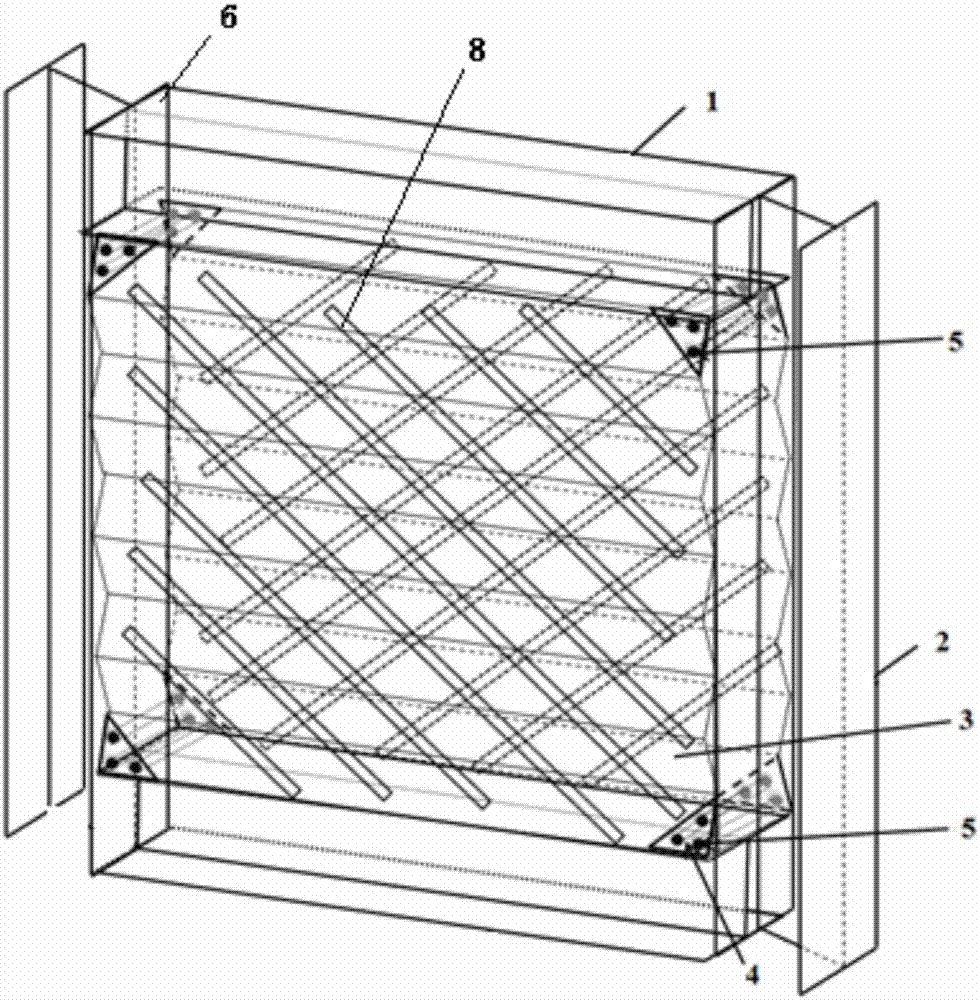

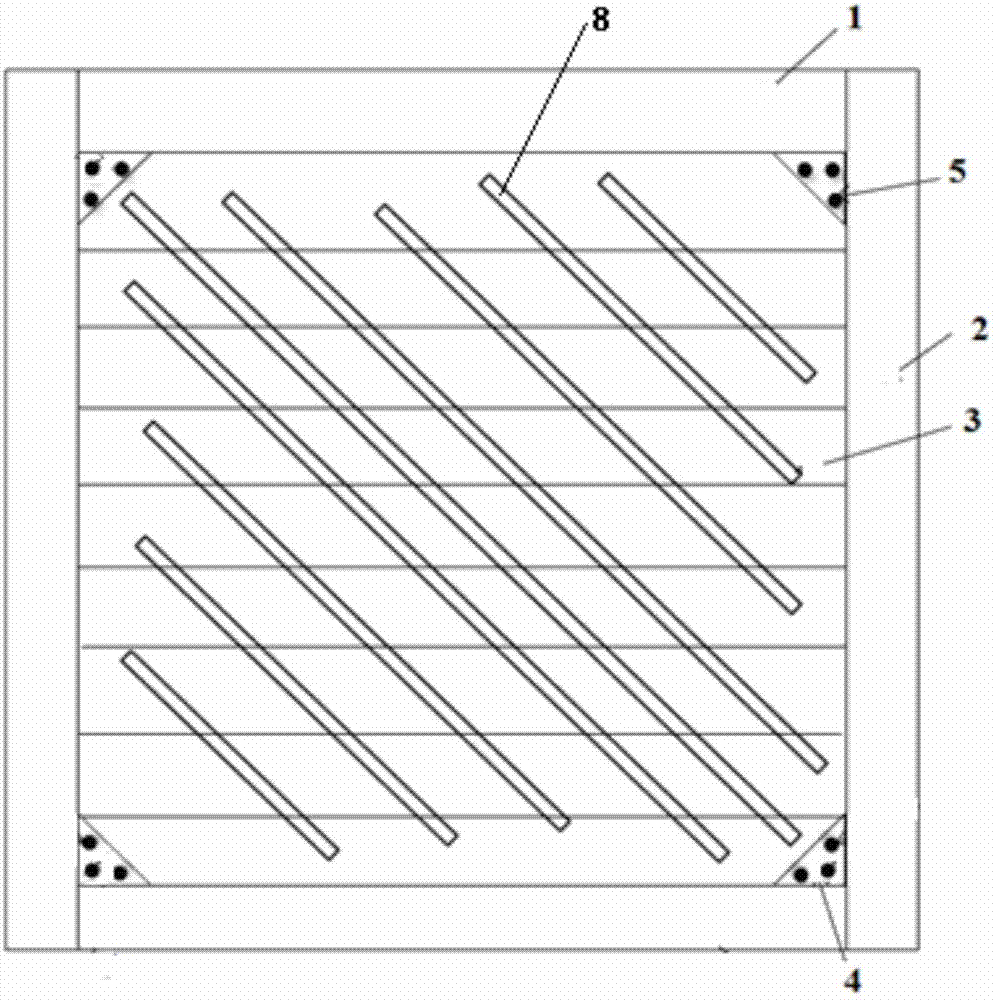

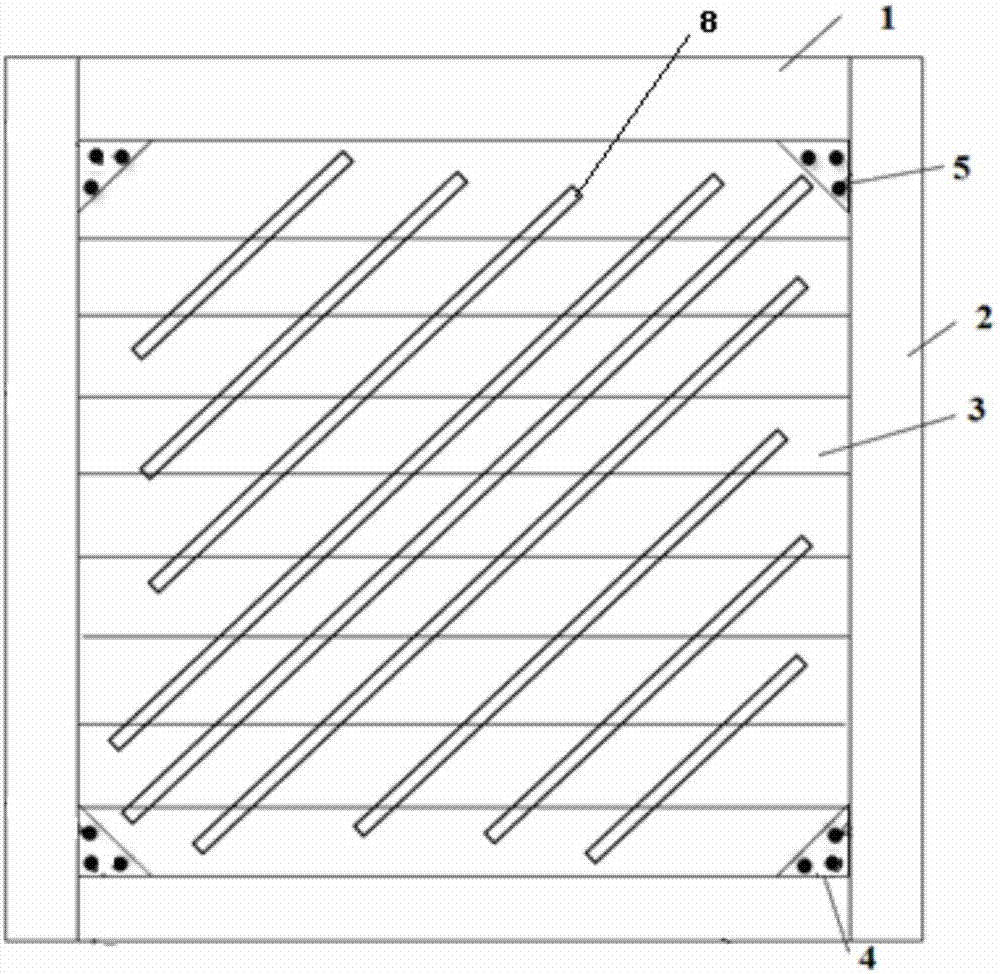

[0021] like Figure 1-Figure 4 Shown is an anti-seismic cross obliquely slotted corrugated steel plate shear wall, including frame beams 1, frame columns 2, corrugated steel plates 3, high-strength bolts 5 and steel backing plates 4;

[0022] The two frame beams 1 and frame columns 2 are fixed together by welding to form a shear wall frame 6;

[0023] The corrugated steel plate 3 is square, and is provided with a plurality of chute 8;

[0024] The four corners of the corrugated steel plate 3 are provided with bolt holes;

[0025] The two layers of corrugated steel plates 3 are connected by high-strength bolts 5 to form a double-layer cross-slanted corrugated steel plate 7;

[0026] Place the double-layer crossed obliquely grooved corrugated steel plate 7 in the frame 6 of the shear wall, and fix it in the frame 6 of the shear wall by welding;

[0027] A steel backing plate 4 is provided between the corrugated steel plate 3 and the high-strength bolt 5 .

[0028] The angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com