1000MPa grade cold rolling hot dip galvanizing two-phase steel and manufacturing method thereof

A manufacturing method and hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc., to achieve the effect of refining grain size, reducing yield strength, and promoting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The chemical compositions of the examples of the present invention are shown in Table 1.

[0026] Table 1 chemical composition (mass percentage)

[0027] make up

No

C

Si

mn

P

S

Al

Cr

Mo

Nb

Ti

N

1

0.12

0.05

1.81

0.006

0.005

0.01

0.33

0.33

0.026

0.015

0.0035

2

0.10

0.05

1.90

0.010

0.004

0.02

0.40

0.30

0.030

0.016

0.0040

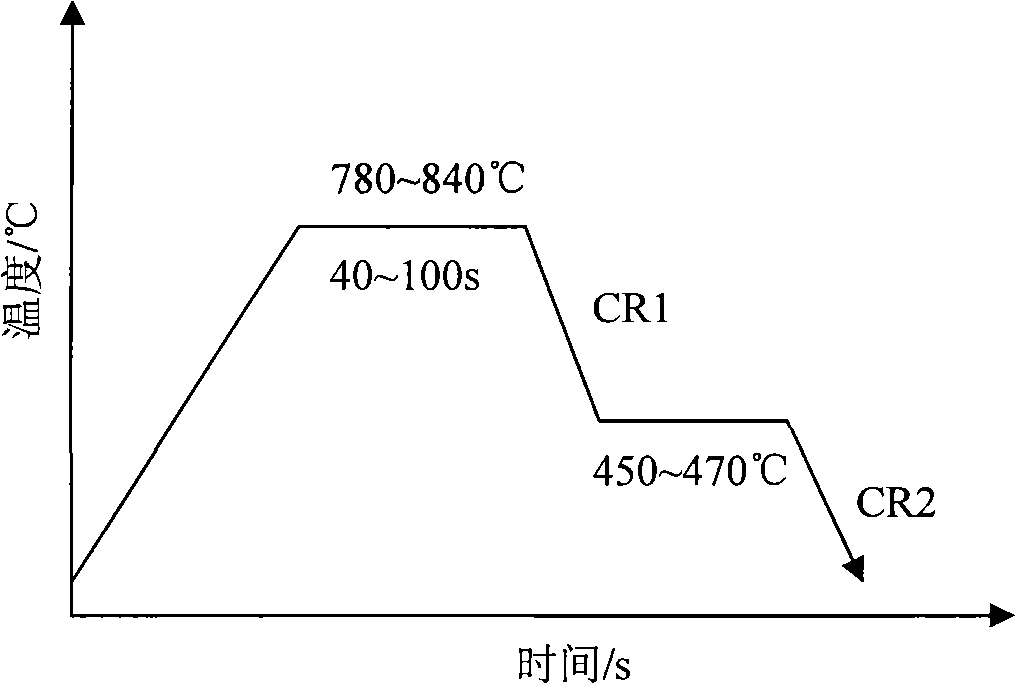

[0028] Table 2 Main process parameters and mechanical properties

[0029]

Example

Annealing temperature / ℃

When keeping warm

Room / s

Yield strong

/ MPa

tensile strength

/ MPa

Elongation

1

820 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com