Steel bar reinforced ECC-steel pipe concrete composite column

A technology of steel pipe concrete and composite columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of insufficient durability, poor synergy between outer layer concrete and inner layer steel pipes, etc., and achieve cost reduction, superior ability to control cracks, The effect of high residual strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

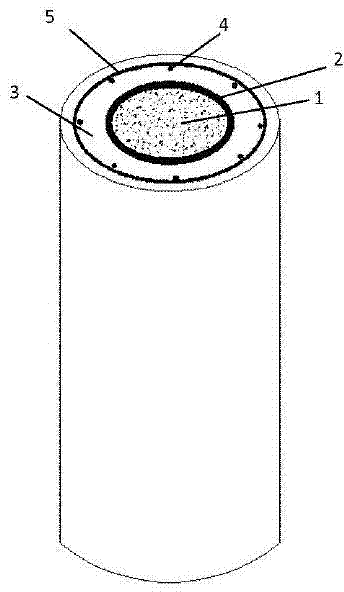

[0048] The reinforced ECC-concrete filled steel tube composite column of this embodiment is as follows: figure 1 and figure 2As shown, it is composed of the outer layer reinforced ECC and the inner layer concrete filled steel tube. The inner layer steel tube concrete is filled with core concrete 1 in the steel tube 2; the outer reinforced ECC is composed of longitudinal bars 4 and circular stirrups 5 to form a steel skeleton , and pouring the external ECC3 composition. The inner steel pipe 2 is an ordinary circular steel pipe, the outer reinforced ECC is flush with the end face of the inner concrete filled steel pipe, and the circular ring formed by the outer reinforced ECC3 coincides with the geometric centroid of the circular section of the inner reinforced steel filled steel pipe.

Embodiment 2

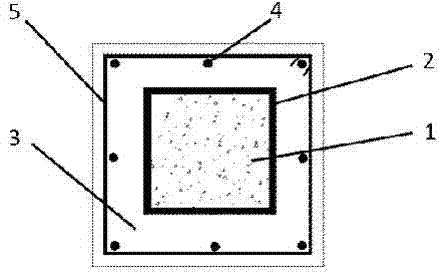

[0050] The reinforced ECC-concrete filled steel tube composite column of this embodiment is as follows: image 3 and Figure 4 As shown, it is composed of the outer layer reinforced ECC and the inner layer concrete filled steel tube. The inner layer steel tube concrete is filled with core concrete 1 in the steel tube 2; the outer reinforced ECC is composed of longitudinal bars 4 and circular stirrups 5 to form a steel skeleton , and pouring the external ECC3 composition. The inner steel pipe 2 is an ordinary square steel pipe, the outer reinforced ECC is flush with the end face of the inner concrete filled steel pipe, and the section formed by the outer reinforced ECC3 coincides with the geometric centroid of the square section of the inner reinforced steel filled steel pipe.

Embodiment 3

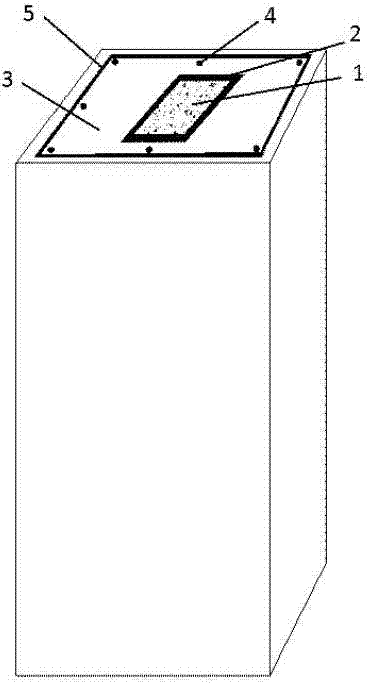

[0052] The reinforced ECC-concrete filled steel tube composite column of this embodiment is as follows: Figure 5 and Figure 6 As shown, it is composed of the outer layer reinforced ECC and the inner layer concrete filled steel tube. The inner layer steel tube concrete is filled with core concrete 1 in the steel tube 2; the outer reinforced ECC is composed of longitudinal bars 4 and circular stirrups 5 to form a steel skeleton , and pouring the external ECC3 composition. The inner steel pipe 2 is an ordinary rectangular steel pipe, the outer reinforced ECC is flush with the end face of the inner concrete filled steel pipe, and the section formed by the outer reinforced ECC3 coincides with the geometric centroid of the rectangular section of the inner reinforced steel filled steel pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com