Basalt type continuous fiber coiled and reinforced bamboo-wood combined pipe

A continuous fiber winding reinforcement technology, applied in the field of basalt continuous fiber winding reinforced bamboo-wood composite pipes, can solve the problems of high density, high cost, and low strength-to-weight ratio, and achieve low density, low cost, and high strength-to-weight ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

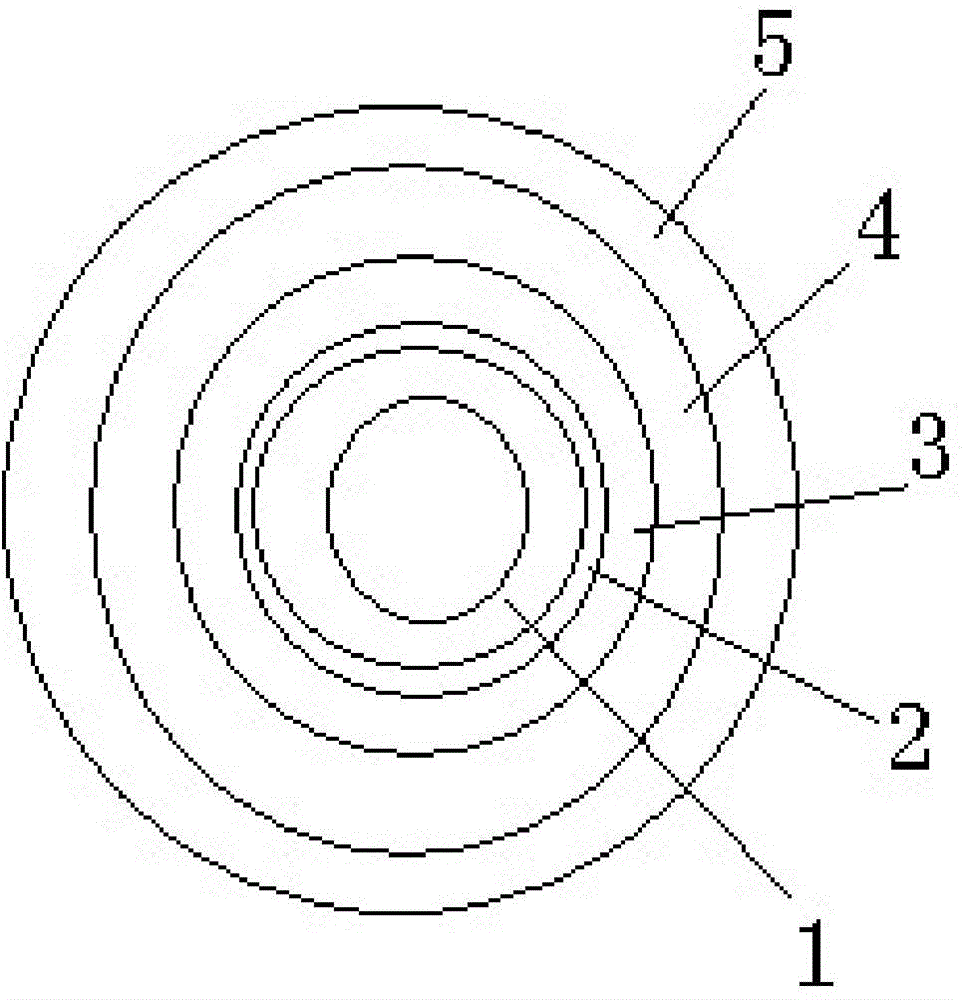

[0012] Basalt continuous fiber winding reinforced bamboo-wood composite pipe of the present invention, its preferred embodiment is:

[0013] Including inner layer fiber reinforced resin, laminated veneer lumber and / or bamboo material, middle layer fiber reinforced resin, veneer laminated lumber and / or bamboo material, surface layer fiber reinforced resin wound sequentially from inside to outside.

[0014] The fiber-reinforced resin is continuous fiber impregnated with resin.

[0015] The resin includes any one or more of the following: polyurethane, epoxy resin, resorcinol, isocyanate, phenolic resin, unsaturated polyester.

[0016] The bamboo material is one or more of the following: bamboo strips, bamboo slices, decomposed bamboo, bamboo rafts, and unfolded bamboo;

[0017] The laminated veneer lumber is one or more of the following: poplar, eucalyptus, birch, fir, masson pine, sylvestris pine.

[0018] The continuous fiber includes any one or more of the following: basalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com