Novel optical cable for communication between underwater equipment and equipment in cabin body

A technology for underwater equipment and internal equipment, which is applied in the field of optical cables for communication between new underwater equipment and equipment inside the cabin, can solve the problems of high bending stiffness and heavy weight, and achieve good bending performance, weight reduction, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

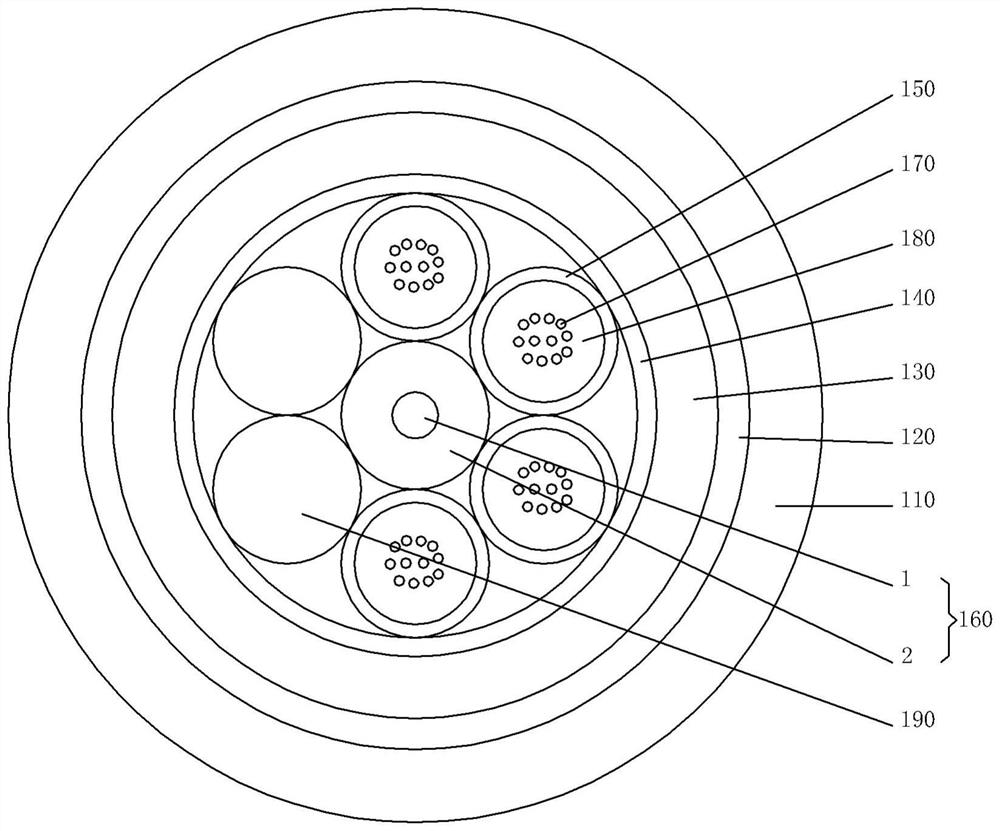

[0021] Optical cables for communication between new underwater equipment and equipment inside the cabin, see figure 1 : The radial center is provided with a central reinforcement 160, a loose tube 150, a strap 140, an inner sheath 130, an aramid braid 120, and an outer sheath 110 in sequence from the inside to the outside, and the central reinforcement 160 is one Aramid extruded flame-retardant sheath, optical fiber 170 is distributed in the inner cavity of loose tube 150, fiber paste 180 is filled in the inner space of optical fiber 170 and loose tube 150, and loose tube 150 is stranded around a central strength member 160, etc. The cable core is effectively circular, the wrapping tape 140 covers the equivalent outer ring of the cable core, the inner sheath 130 covers the outer ring of the wrapping tape 140, and the outer ring of the inner sheath 130 is covered with a layer of aramid braiding layer , the outer ring of the aramid braid is covered with an outer sheath.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com