Plastic-coated wooden building template and preparation method thereof

A technology of building templates and wooden molds coated with plastic, which is applied to the preparation of building components on site, formwork/formwork components, construction, etc., which can solve the problems of poor mechanical properties and low turnover times of building templates, and achieve low cost and high surface quality. Easy to clean and maintain, and the effect of wide template width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

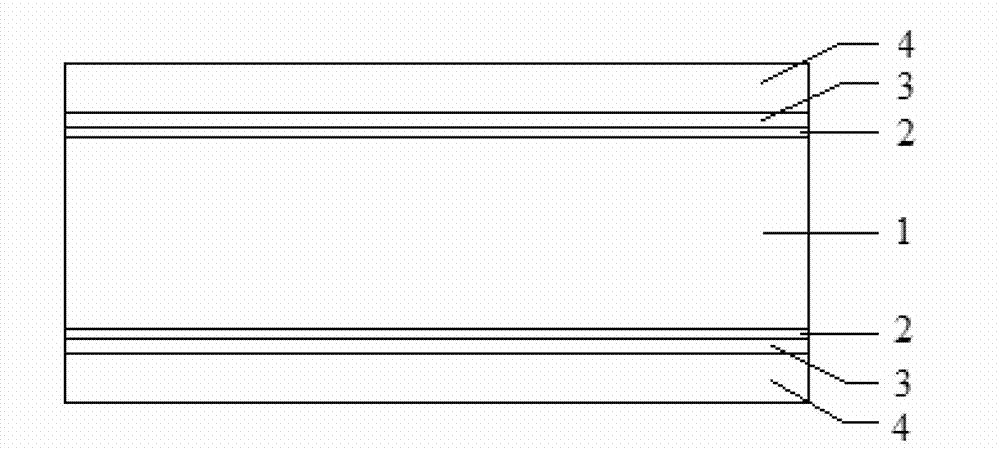

[0023] Specific implementation mode one: reference figure 1 , a wooden mold-coated building template in this embodiment is to paste a layer of veneer 2 on the upper and lower surfaces of the core board 1 made of waste templates. The thickness of the veneer 2 is 0.8-1 mm, and then the A layer of veneer is pasted on the surface of the veneer 2 on the upper and lower surfaces of the veneer, and the thickness of the veneer is 0.5-3mm. Each layer of veneer is composed of a polyolefin material layer 4 and a non-woven fabric 3, and the non-woven fabric 3 is located between the veneer 2 and the veneer. Between the polyolefin material layers 4; the polyolefin material layer 3 is composed of 85%-100% polyolefin and 0-15% filler by mass percentage, and the filler is talcum powder or calcium carbonate powder.

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the thickness of the veneer (2) is 1-2.5 mm, the thickness of the veneer is 1-2 mm, and the polyolefin material layer (4) is made according to The mass percentage is composed of 90%-95% polyolefin and 5%-10% filler. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the thickness of described veneer (2) is 1.8mm, the thickness of veneer is 1.5mm, other is identical with specific embodiment one or two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com