Preparation method of organic and inorganic wood composite material

A composite material and wood technology, which is applied in the field of composite material preparation, can solve problems such as poor mechanical properties and poor durability, and achieve the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

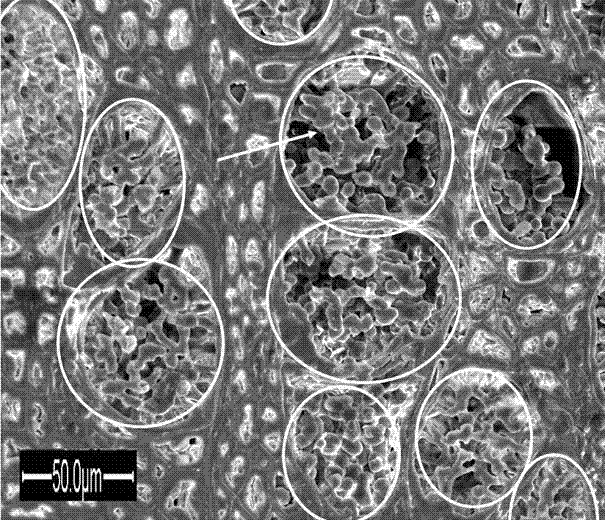

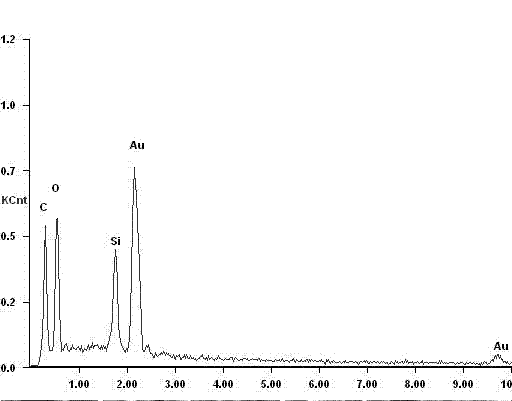

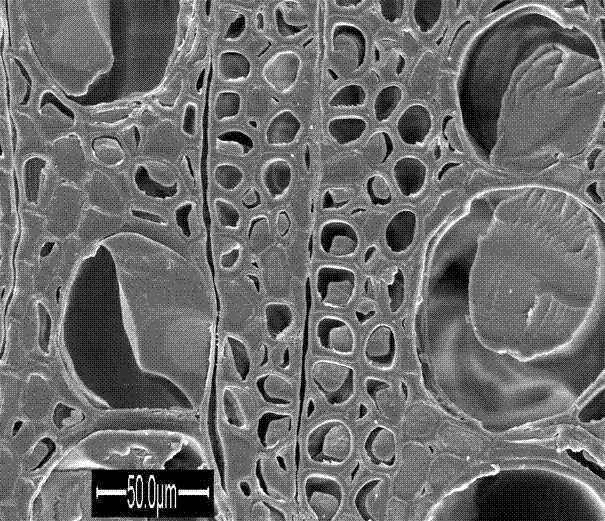

Image

Examples

specific Embodiment approach 1

[0010] Specific Embodiment 1: The preparation method of wood-organic-inorganic hybrid composite material in this embodiment is as follows: 1. Prepolymerization of monomer: add 80g~140g of polymerizable monomer and silane coupling agent to 90ml~100ml THF The mixture, the molar ratio of the polymerizable monomer to the silane coupling agent is 2~20:1, then add 0.3%~0.4% initiator of the polymerizable monomer and silane coupling agent mixture, mix well and continue to stir for 15 minutes , and then polymerized under nitrogen protection and 60°C for 70 minutes, continued to stir for 10 minutes, and cooled to room temperature to obtain the pre-polymerization cooling liquid of the monomer; 2. Preparation of dilute sol: 30~80g organosilane, removed Dissolve the mixture of ionized water and hydrochloric acid in 20ml~30ml of tetrahydrofuran, mix evenly, then add monomer pre-polymerization cooling liquid, stir for 15 minutes to obtain a dilute sol, in which the molar ratio of organosilan...

specific Embodiment approach 2

[0012] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the polymerizable monomers described in step 1 are glycidyl methacrylate (GMA), methyl methacrylate (MMA), butyl methacrylate (BMA), 2-Hydroxyethyl Methacrylate (HEMA), Styrene (St), Vinyl Acetate (VAc), Ethylene Glycol Dimethacrylate (EGDMA), Tripropylene Glycol Diacrylate (TPGDMA) , tetraethylene glycol dimethacrylate (TEGDMA), allyl glycidyl ether (AGE), trimethylolpropane triacrylate (TMPTA), polymaleic acid-phthalate-1,2-propane One or a combination of diesters and polymaleic acid-phthalate-oxydiethyl esters. Others are the same as in the first embodiment.

[0013] In this embodiment, when the polymerizable monomer is a composition, the ratio between the components is arbitrary.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the silane coupling agent in step 1 is γ-methacryloxypropyltrimethoxysilane (KH570), vinyl Trimethoxysilane (SG-Si 171), vinyltris(2-methoxyethoxy)silane (SG-Si 172), vinyltriethoxysilane (SG-Si 151), γ-aminopropyl Triethoxysilane (KH550), γ-aminopropylmethyldiethoxysilane (SG-Si902) or N-β(aminoethyl)-γ-aminopropyltrimethoxysilane (SG-Si900 (SG-Si 1122)). Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com